27

This concludes adjusting your saw where you have removed all "looseness" or slack between the

different parts of the saw. The next section deals with actually aligning the sawblade to get accu-

rate cuts.

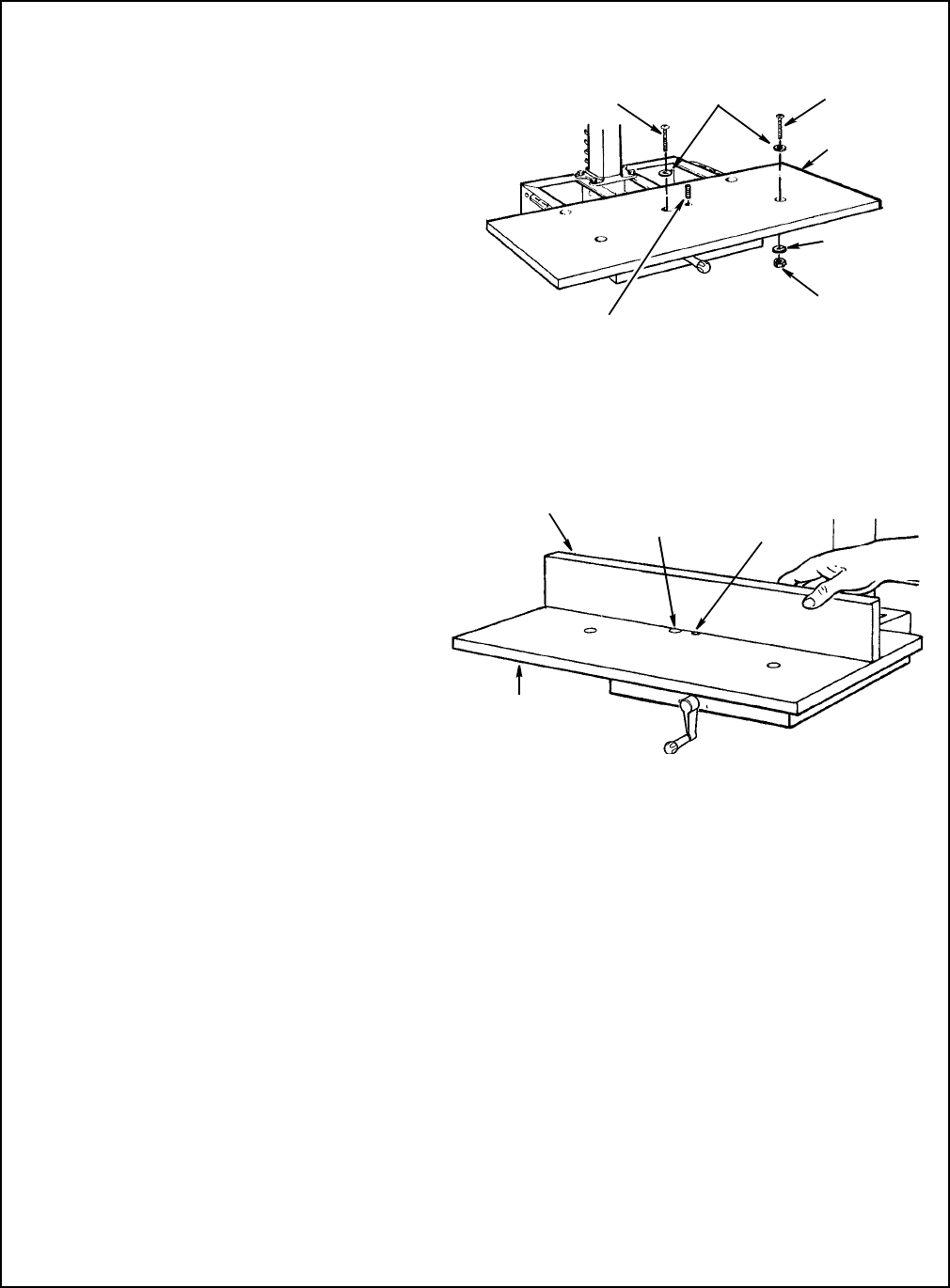

5. Drop a flat washer into each counter-

bored hole.

6.

Start 1-3/4" long pan head screw through

center hole and into U-clip, but do not fully

tighten.

7. Start cup point set screw through leveling

hole and into tee nut, but do not fully tighten.

8. Put 1" long pan head screw in each of

four remaining holes and through matching

holes in table supports. Place lockwasher

and nut on the end of each screw, and

tighten with screwdriver.

Make Front Table Flat

1. Place rear table on its edge, across cen-

ter of front table. Check for gap between sur-

faces.

Ifthereisagap,close gap by raising or low-

ering center of front table:

to raise center, tighten cup point set screw

against frame;

to lower center, tighten center (1-3/4" long)

pan head screw.

2. When gap is closed, make sure cup point

set screw touches frame (look underneath

table), and center (1-3/4" long) pan head

screw is tightened.

1/4-20 x 1-3/4"

Pan Head Screw

17/64"

Flat Washer

1/4-20 x 1"

Pan Head Screw

Front Table

Lockwasher

Hex Nut

1/4-20 x 1"

Cup Point Set Screw

Rear Table

Board

Hold Down

Screw

Leveling

Set Screw

Front Table

Adjustments