21

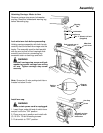

Bevel Lock Lever

The purpose of the bevel lock lever is to lock

the motor at any angle. To check follow these

steps:

1. Unlock the bevel lock lever. Move the

bevel index pin to the left and rotate the saw

to approximately 30°. Lock the bevel lock

lever.

2. Use both hands as shown and try to force

the motor out of position. If the motor moves,

the bevel lock lever needs to be tightened.

On the other hand if it is extremely hard to

lock the bevel lock lever it has been over

-tightened.

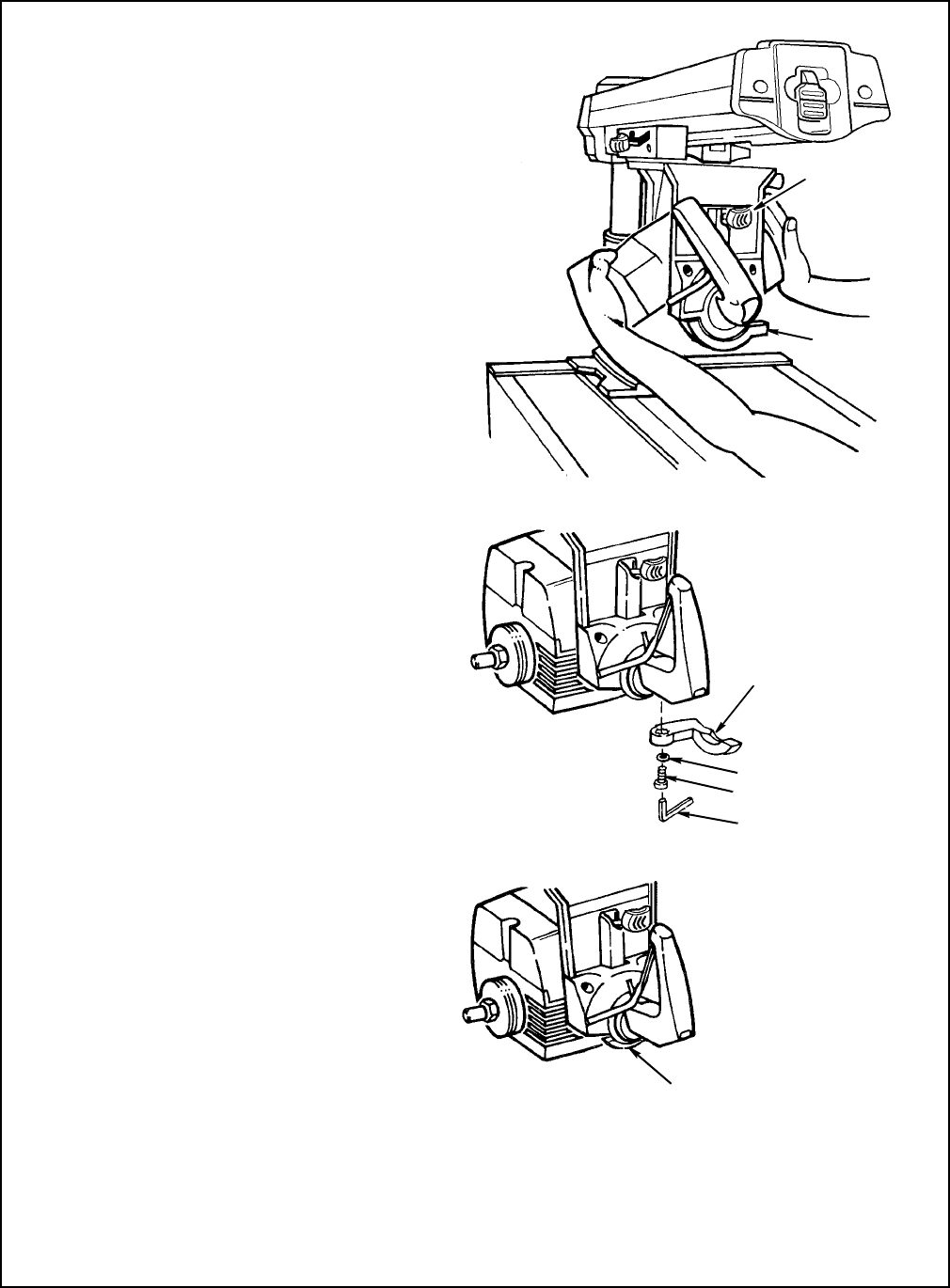

3. Follow these steps to adjust:

a. Remove the socket cap screw with hex

wrench as shown.

b. Use the bevel lock lever as a wrench to

tighten or loosen the clamp bolt. Do not

over tighten.

c. Repeat steps 1 and 2. Re-adjust if nec-

essary.

d. Replace bevel lock lever in the locked

position.

e. Tighten the socket cap screw.

Note:

The clamp bolt has a left handed thread.

Therefore, to increase the clamping effect, rotate the

bevel lock lever - when used as a wrench -from right to

left, or clockwise when viewed from above. If you acci-

dentally rotate it the wrong way and disengage the bolt

from the matching steel nut, it will be necessary to

remove the Yoke Handle, and Bevel Scale, in order to

reinstall the bolt into the nut.

Bevel Index

Pin

Bevel Lock

Lever

Bevel Lock

Lever

Lockwasher

Socket Cap Screw

1/8" Hex “L” Wrench

Bevel Lock Lever

In Locked Position

Adjustments