23

3. Rotational Alignment Check:

While holding the arm with one hand, hold

fingers of other hand as shown, between col-

umn tube and column support. Apply gentle

side-to-side pressure at end of arm. Any

side-to-side or rotational movement can be

felt with finger at arrow location.

Alignment Adjustments

Note:

If Vertical Alignment was OK and adjustment is

not

needed, proceed to step 6.

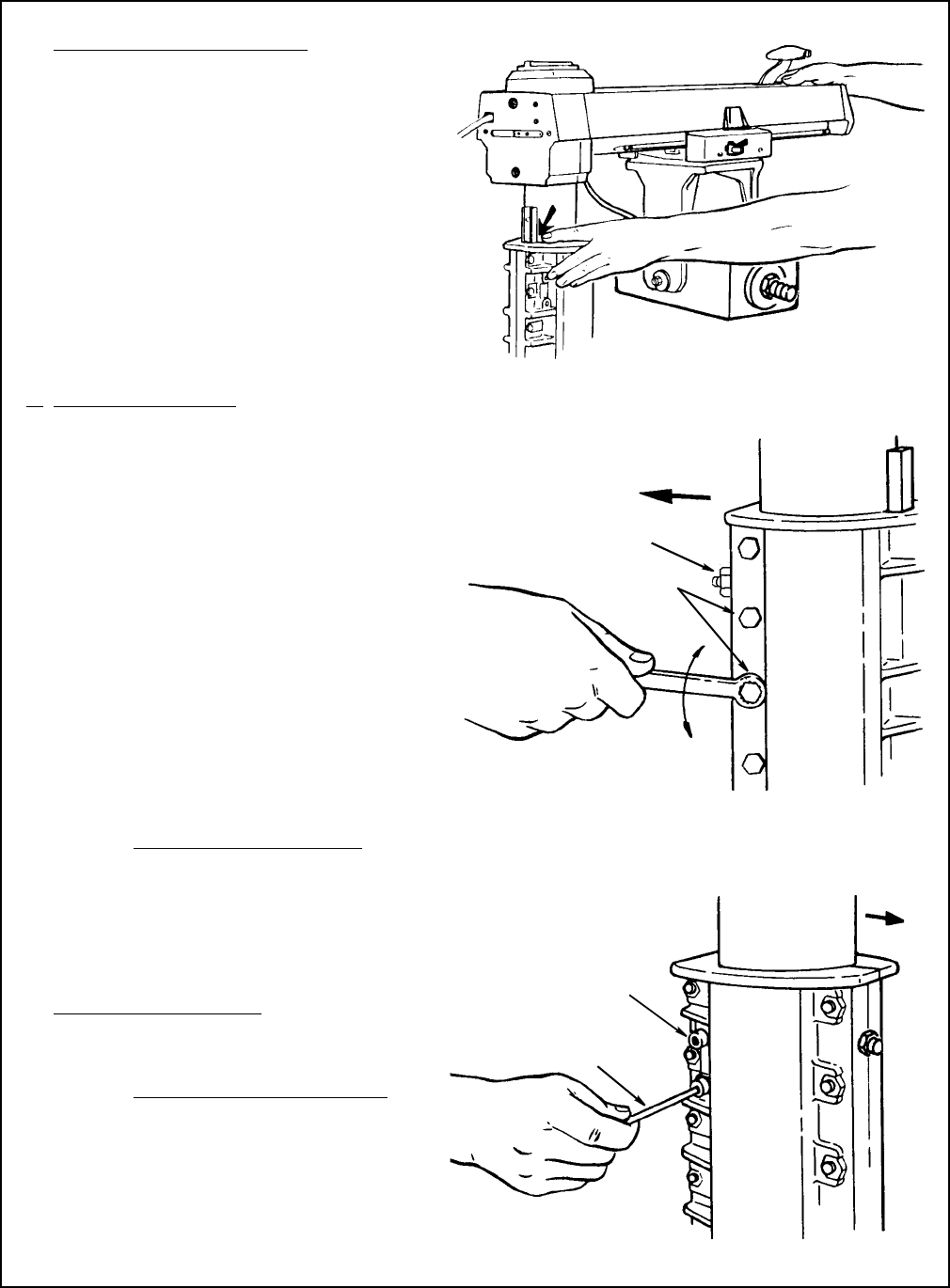

1. Loosen (2) 1/4 - 20 Gib socket cap

screws on the left side at the rear of the col-

umn support slightly (1/2 turn).

2.

Vertical Adjustment:

Using the closed end of a box wrench, tighten

all of the 5/16-18 black screw heads on the col-

umn support casting 1/16th to 1/8th of a turn.

Tighten the (2) 5/16-18 silver screw heads

slightly more than the black ones to achieve a

close fit to the column tube (Fig. 2). (A 1/4"

drive ratchet with a six point socket may be

needed to get enough torque on bolts.) Loosen

nut on brass set screw. Tighten the brass set

screw firmly and retighten nut (Fig. 2).

3. Elevate and then lower the Arm using the

elevation crank.

4. If the column tube binds and elevation is

difficult, go back to step 2 and loosen the

screws until you achieve smooth but firm ele-

vation, recheck step 3.

5. Repeat "Vertical Alignment Check

".

a. If vertical misalignment still exists,

repeat steps 2 through 4.

b. If vertical misalignment no longer

exists, and you have achieved smooth but

firm elevation, proceed to step 6.

6. Rotational

Adjustment:

Tighten the (2) 1/4-20 Gib socket cap screws

until no noticeable rotational play exists. (Fig. 3).

7. Repeat "Rotational Alignment Check"

a. If rotational misalignment still exists,

repeat step 6.

b. If rotational misalignment no longer

exists, and you have achieved smooth but

firm elevation, this alignment procedure is

complete.

Fig. 1

Front

Bright Plated

Bolts

Tighten

Loosen

Fig. 2

Brass Set Screw

Front

Gib Socket

Capscrews

Hex “L” Wrench

(Supplied)

Fig. 3

Adjustments