22

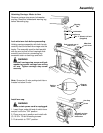

Arm to Column Adjustment

If you can move the end of the radial arm up

and down when the arm is unlocked, adjust

as directed below:

a. Remove two (2) screws from rear cover

plate. Tighten evenly top two 3/8-16 bolts

until the play is removed and the arm will still

move side to side freely. There should be no

vertical or horizontal movement in the arm

when miter/arm lock is locked and unlocked.

b. Bottom two nuts should be snugged

evenly, but not nearly as tight as top two bolts.

c. Re-install Rear Cover Plate.

Adjusting Column Tube in Column Support

This adjustment will remove any looseness

between the column tube and column sup-

port while serving two purposes:

• To insure accurate cuts; and

• To allow the column tube to raise and

lower smoothly.

Note:

The following adjustment is

very critical

.

All future alignment procedures rely on this adjustment

being performed correctly. All looseness must be

removed.

This section is set up in two sections:

Alignment checks and adjustments. It is very

important that the column tube and the

inside of the column support are coated with

a film of uncontaminated lubricant.

Alignment Checks

Two checks are required, these are adjusted

at the factory, but may have shifted during

shipment.

1. Index and lock arm at 0° Miter.

2.

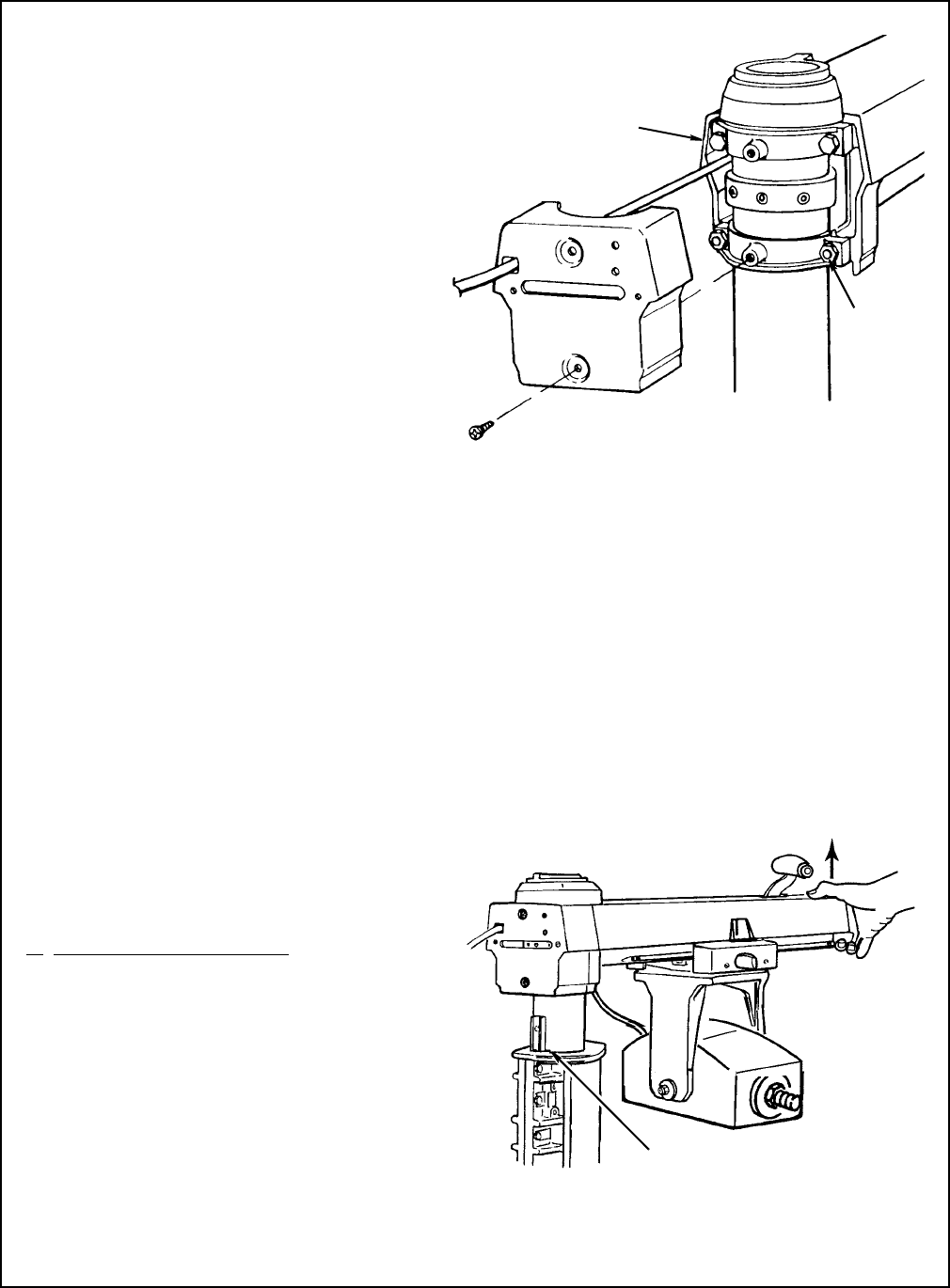

Vertical Alignment Check:

The two piece column support needs to be

compressed by tightening the black and sil-

ver screws to properly control the movement

of the column tube. Precise alignment is

done only by tightening or loosening the sil-

ver 5/16-18 screws in combination with the

brass set screw. Push up slightly on the end

of the arm. Look for a noticeable movement

between the column tube and the column

support.

3/8-16 Bolts

3/8-16 Nuts

Upward

Pressure

Look for Movement

Between Column Tube

and Support

Adjustments