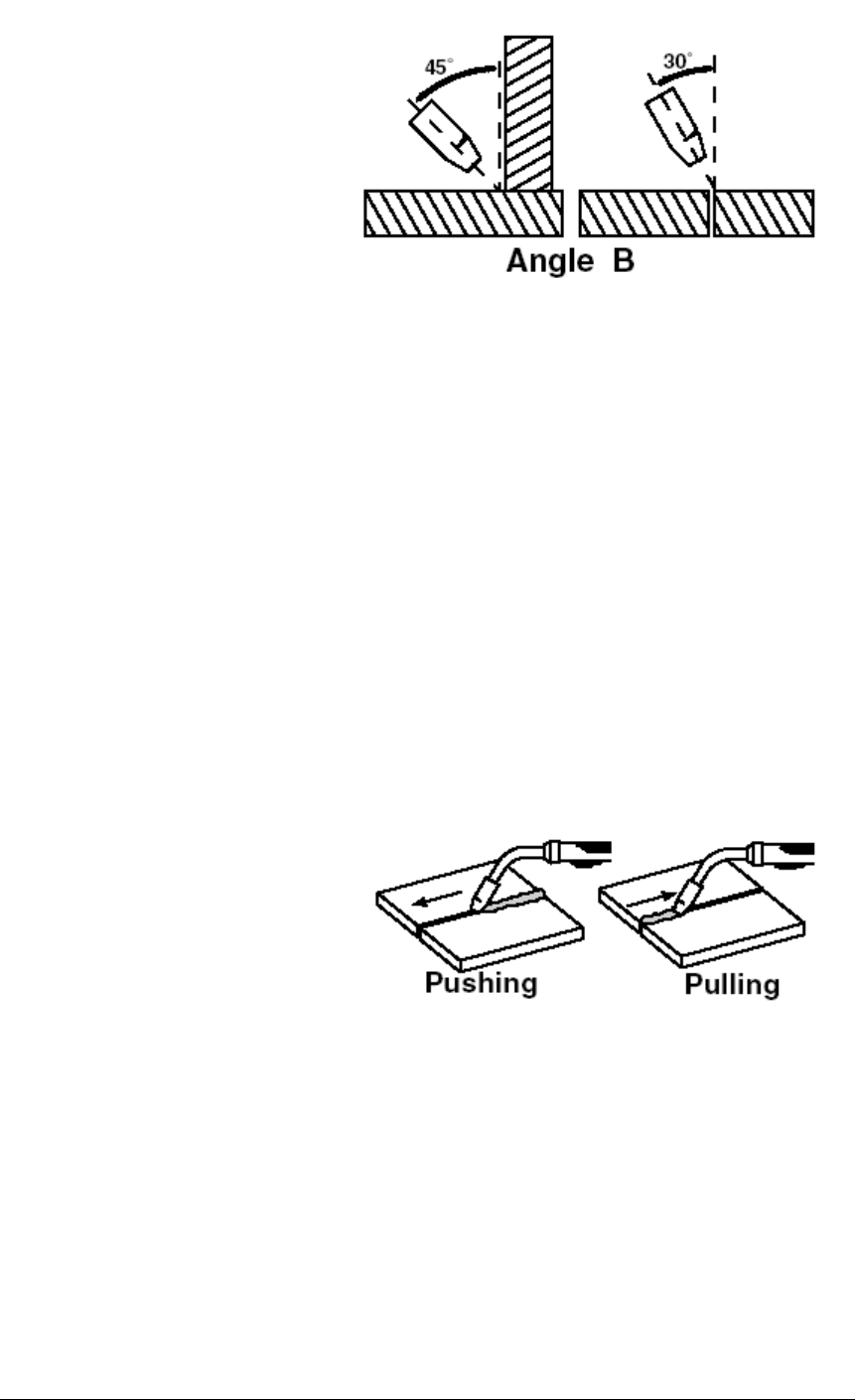

2. Angle B can be varied for two reasons: to improve the ability to see the arc in relation to the

weld puddle and to direct

the force of the arc. The

force of the welding arc

follows a straight line out of

the end of the nozzle. If

angle B is changed, so will

the direction of arc force

and the point at which

penetration will be

concentrated. On a butt

weld joint, the only reason

to vary angle B from

perpendicular (straight up)

to the work piece would be to improve visibility of the weld puddle. In this case, angle B can

be varied anywhere from zero to 45 degrees with 30 degrees working about the best.

On a fillet weld joint, the nozzle is generally positioned in such a manner so as to split the

angle between the horizontal and vertical members of the weld joint. In most cases, a fillet

weld will be 45 degrees.

Distance from the Work Piece

The end of the welding gun is designed with the contact tip recessed from the end of the nozzle and

the nozzle electrically insulated from the rest of the gun. This permits the operator to actually rest the

nozzle on the work piece and drag it along while welding. This can be very helpful to beginning

welders to steady the gun, allowing the welder to concentrate on welding technique. If the nozzle is

held off the work piece, the distance between the nozzle and the work piece should be kept constant

and should not exceed 1/4 inch or the arc may begin sputtering, signaling a loss in welding

performance.

WELDING TECHNIQUES

MOVING THE GUN

Gun travel refers to the movement of the gun along the weld joint and is broken into two elements:

Direction and Speed. A solid weld bead requires that the welding gun be moved steadily and at the

right speed along the weld joint. Moving the gun too fast, too slow, or erratically will prevent proper

fusion or create a lumpy, uneven bead.

1. TRAVEL DIRECTION is the

direction the gun is moved

along the weld joint in

relation to the weld puddle.

The gun is either PUSHED

into the weld puddle or

PULLED away from the

weld puddle. For most

welding jobs you will pull the

gun along the weld joint to take advantage of the greater weld puddle visibility. However,

there are a few applications where pushing the gun may provide some advantages:

VERTICAL WELDING can be done by starting at the top of a weld joint and pulling the gun

down toward the bottom. However, in the event that puddle control becomes difficult (such as

the puddle wanting to run downward), starting a vertical weld at the bottom of a weld joint and

pushing the gun up toward the top will help to overcome this problem.

2. TRAVEL SPEED is the rate at which the gun is being pushed or pulled along the weld joint.

For a fixed heat setting, the faster the travel speed, the lower the penetration and the lower

and narrower the finished weld bead. Likewise, the slower the travel speed, the deeper the

penetration and the higher and wider the finished weld bead.

15