GENERAL MAINTENANCE

This welder has been engineered to give many years of trouble-free service providing that a few very

simple steps are taken to properly maintain it. Before performing any maintenance or service on your

welder, read and understand all warnings in this manual. Unless instructed otherwise, always unplug

the welder prior to maintaining or servicing it.

1. Keep the hood closed at all times unless the wire needs to be changed or the drive tension

needs adjusting.

2. Keep all consumables (contact tips, nozzles, and gun liner) clean and replace when

necessary.

3. Replace the power cord, ground cable, ground clamp, or gun assembly when they become

damaged or worn.

4. Periodically clean dust, dirt, grease, etc. from your welder. Every six months or as necessary,

remove the side panels and air-blow any dust and dirt that may have accumulated inside the

welder.

MAINTAINING THE WELDER

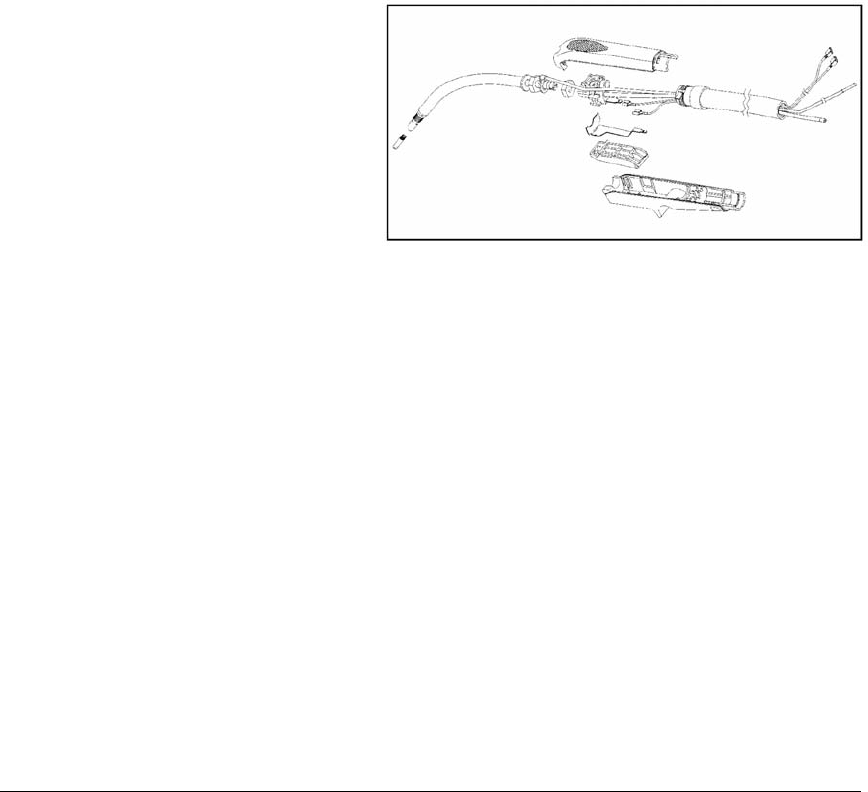

Welding Gun Liner

The gun liner is intended to provide a replaceable, unrestricted path for the welding wire to pass

through the gun assembly. Over time it will accumulate dust, dirt, and other debris. Replacement is

necessary when these accumulations begin to restrict the free flow of wire through the gun assembly.

When removing or installing a gun liner, care must be taken not to kink or otherwise damage it or

replacement will be necessary.

To Replace a Gun Liner

1. Turn the VOLTAGE switch to the OFF position.

2. Remove the nozzle and contact

tip from the gun.

3. Remove the welding wire from the

gun assembly.

4. Remove the four (4) phillips head

screws from the gun clamp.

5. Remove the gas line from inside

of welder

6. Remove the electrical connections

from inside of welder.

7. Remove the gun assembly from the front of the welder.

8. Lay out the gun assembly in a straight line.

9. Remove the four (4) screws from the handle of the gun assembly.

10. Unscrew the liner from the brass block and remove it from the gun assembly.

11. Slide the new liner through the gun cable, fasten it to the block and re-assemble the handle.

12. Reinstall the gun assembly into the welder.

Contact Tip Maintenance and Replacement

The purpose of the contact tip is to transfer welding current to the welding wire while allowing the wire

to pass through it smoothly.

1. Always use a contact tip stamped with the same diameter as the wire with which it will be

used.

2. If the wire burns back into the tip, remove the tip from the gun and clean the hole running

through it with an oxygen-acetylene torch tip cleaner. This is especially important to do after

an aluminum wire burn-back.

3. Over time, the hole in the contact tip will become worn by the wire passing through it.

16