-48-

For Machines Mfg. Since 8/09

Model SB1027

MAINTENANCE

Coolant Reservoir

A small amount of coolant is lost during normal

operation. Check the coolant reservoir regularly

and fill it if necessary. We recommend changing

the coolant every three months or sooner if it

develops an unpleasant odor.

The coolant reservoir holds approximately five

gallons (19 liters) of fluid.

Checking Coolant Level

Tools Needed Qty

Hex Wrench 3mm .................................................1

Piece of Wire ..........................................................1

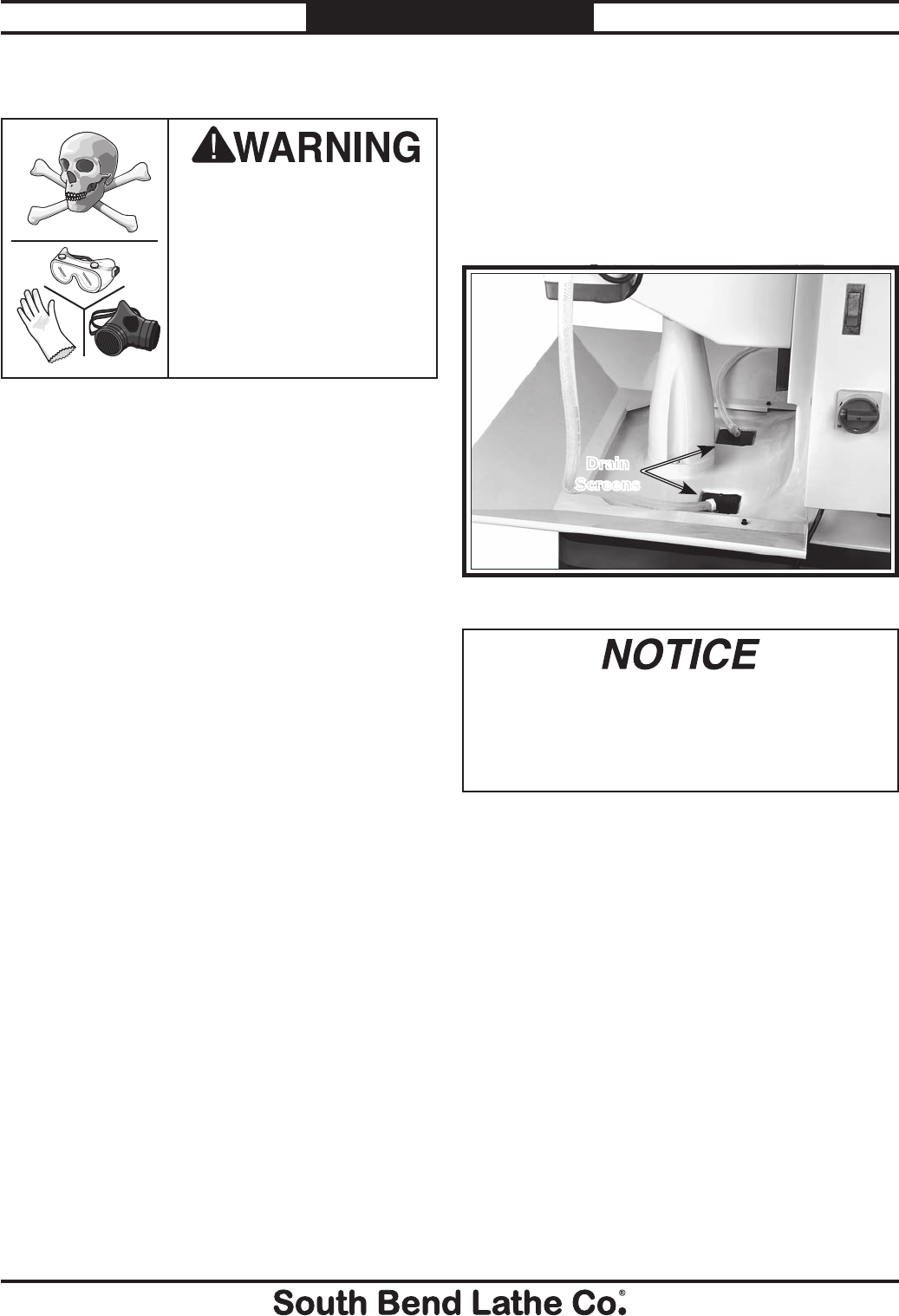

Figure 56. Locations of the coolant drain screens.

Drain

Screens

Running the coolant pump without adequate

coolant in the reservoir may permanently

damage the coolant pump. This action is

considered abusive and is not covered by the

warranty.

3. If the level of coolant in the reservoir is less

than 2", add more fluid through the screen to

fill the tank.

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment

when handling cutting

fluid. Follow federal, state,

and fluid manufacturer

requirements for proper

disposal.

To check the coolant level:

1. DISCONNECT MILL FROM POWER!

2. Clean away debris and grime from the

coolant drain screens on the base of the mill

(see Figure 56), then insert a clean and dry

piece of wire through one of the screens to

check the level of the coolant.