-66-

For Machines Mfg. Since 5/11

13" x 40" Heavy 13

®

EVS Lathe

MAINTENANCE

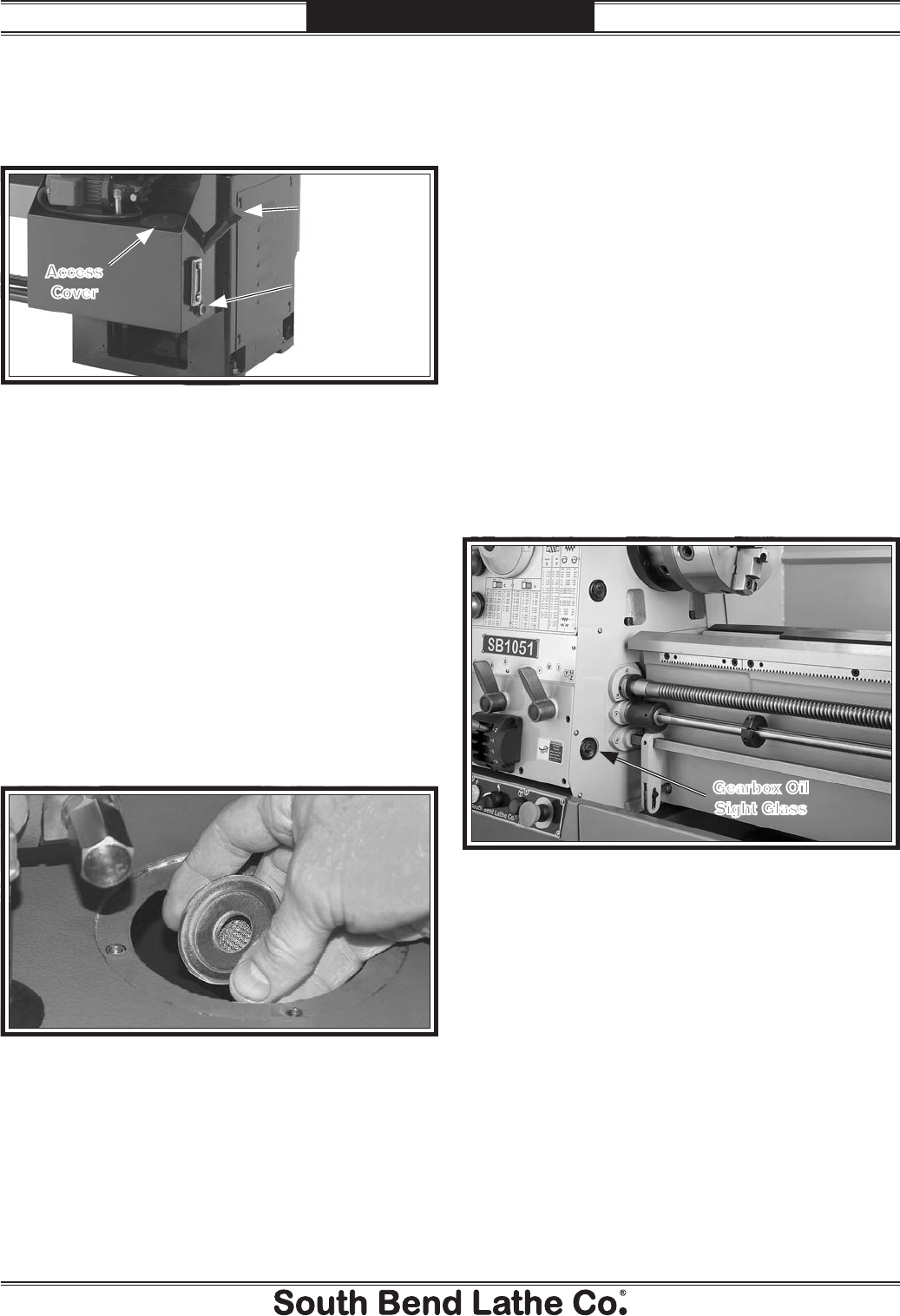

9. Clean away grime and debris from the oil

tank access cover (see Figure 100), then

unthread the four cap screws to remove the

cover.

10. Using mineral spirits and shop rags,

thoroughly clean the inside of the oil tank.

Make sure to soak up any excess mineral

spirits to avoid contaminating the new oil.

11. Reach into the tank and remove the filter

screen (see Figure 101) from the bottom of

the suction pipe. Thoroughly clean it with

mineral spirits and compressed air, allow to

dry, and re-install it.

Figure 101. Suction pipe filter screen.

Tip: Place one or more magnets at the bottom of

the tank to collect any fine metal particles.

This will make cleaning easier the next

time and reduce the risk of metal particles

entering the pump.

12. Re-install the drain plug, fill the tank with

oil, then re-install the fill spout cover.

Quick-Change Gearbox

Oil Type ......Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount ............................................ 1.4 Quarts

Check/Add Frequency ....................................Daily

Change Frequency ...................................Annually

Checking Oil Level

The gearbox reservoir has the proper amount of

oil when the sight glass, shown in Figure 102, is

approximately halfway full.

Figure 100. Headstock oil fill spout and drain plug.

Oil Fill

Spout

Drain

Plug

Access

Cover

8. Remove the oil fill spout cover, place the

catch pan under the oil tank drain plug (see

Figure 100), and remove the drain plug to

empty the tank.

Figure 102. Location of quick-change gearbox oil sight

glass.

Gearbox Oil

Sight Glass