-78-

For Machines Mfg. Since 5/11

13" x 40" Heavy 13

®

EVS Lathe

SERVICE

Brake & Switch

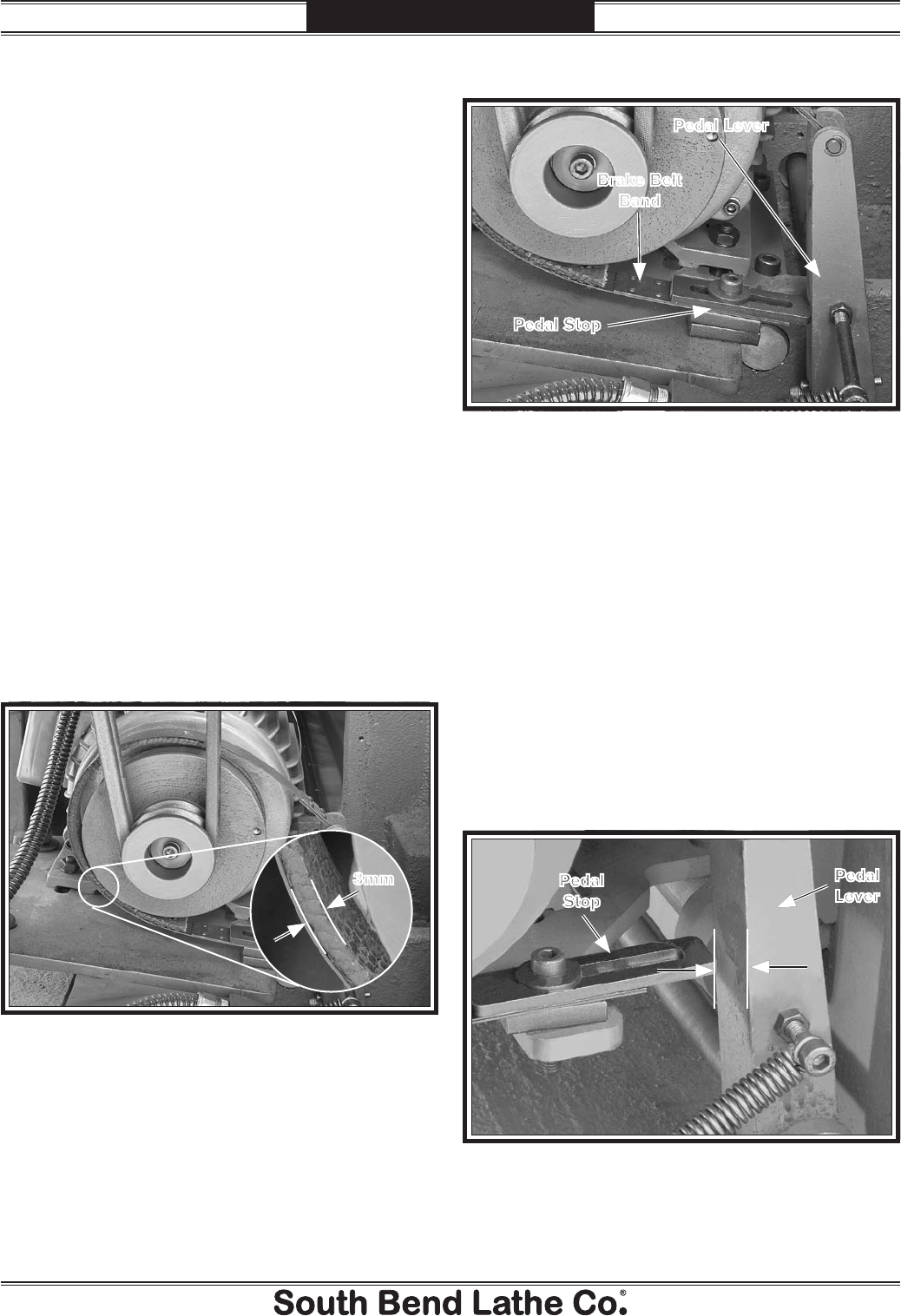

As the brake lining wears, the foot pedal

develops more travel. If the brake band is not

adjusted to compensate for normal wear, the

limit switch will still turn the lathe off, but the

spindle will not stop as quickly. It is especially

important that the brake is kept properly

adjusted so you can quickly stop the spindle in

an emergency.

Tools Needed: Qty

Phillips Screwdriver #2 ........................................1

Hex Wrench 6mm .................................................1

To adjust the brake and brake switch:

1. DISCONNECT LATHE FROM POWER!

2. Put on a respirator and eye protection to

protect yourself from hazardous brake dust.

3. Remove the motor access panel from the left

cabinet.

4. Measure the remaining brake band lining at

the thinnest point, which is usually at the

8 o'clock position, as shown in Figure 126.

When the brake band is new, the lining

is approximately 6mm thick. If the lining

thickness wears to 3mm or less, the brake

band must be replaced. Otherwise, the rivets

that secure the lining to the band will soon

grind into the brake hub. If the hub becomes

damaged, it must be replaced.

Figure 126. Minimum brake belt thickness.

3mm

5. Remove the pedal stop shown in Figure 127.

6. Move the brake band to the right one hole,

and re-install the pedal stop, tightening the

cap screw until it is just snug.

Note: If installing a new brake band, install the

cap screw so there is one hole to the left for

future brake adjustment.

7. Firmly push the pedal lever to the right until

it stops and the brake band is fully clamped

around the brake hub.

8. Tap the pedal stop into position so there

is approximately a 25mm gap between the

pedal lever and the stop (see Figure 128),

then firmly tighten the pedal stop cap screw.

Figure 127. Brake belt adjustment components.

Pedal Stop

Pedal Lever

Brake Belt

Band

Figure 128. Brake pedal travel adjustment.

Pedal

Lever

Pedal

Stop