Installation Model 7500ZA

Teledyne Analytical Instruments 10

• Entry of dust into the instrument may result in poor performance.

Use clean tubing and couplings.

•

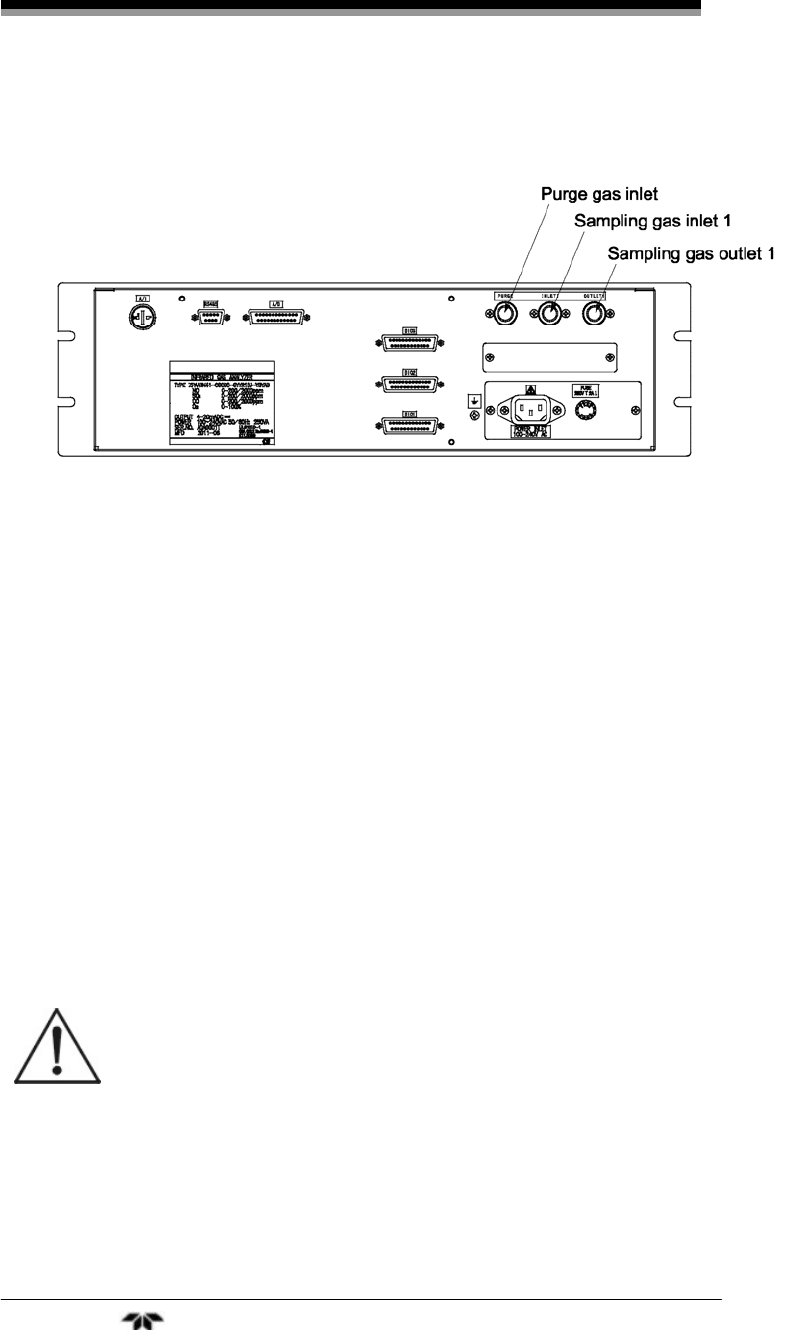

Sample inlet: Attach clean, dry sample gas to the inlet port.

Note that the calibration gases ( zero and span)

also connect to this port.

Input gas flow t should be constant within the

range of 0.5 L/min ±0.2 L/min.

Sample outlet: Attach tubing for exhausting sample or calibration

gases. The exhaust line should be directed to an

appropriate safe vent depending on the nature of

the sample/calibration gas used.

Purge gas inlet: Used to connect a purge gas for purging the

internal housing of the analyzer. Use dry N

2

or

instrument air for purge gas. (Flow rate is 1L/min

or more. Keep dust or moisture/mist from

entering the purge line.

CAUTION: THIS INSTRUMENT IS DESIGNED TO HANDLE

HAZARDOUS GASES. WHENEVER A FITTING IS

OPENED, USE A NEW FERRULE AND CONE TO

SECURE A GAS TIGHT SEAL. EACH FITTING MUST

BE LEAK CHECKED WHENEVER A CONNECTION

HAS BEEN OPENED OR DISTURBED IN ANY

MANNER.

The internal piping diagram for the Model 7500ZA is shown

below.