42

Plast Coat 430

GB

6 COMMISSIONING

6.1 INSTALLATION LOCATION

Themortarsprayingmachineandthebucketfromwhichthe

material to be processed is to be pumped have to be set up on

an even and rm underground. This ensures that the machine

andbucketcannotslideawayorfallover.

6.2 INITIAL STARTINGUP

6.2.1 SCOPE OF SUPPLY

Themachineissuppliedbythemanufacturerinthefollowing

individual components:

• Completebasicmachinecomprisingdriveunit,controlunit

and transport frame with wheels

• Pump unit complete

• Tool:Specialkey

• Hose package

• Spraylance

• Pump sliding means

6.2.2 ASSEMBLY

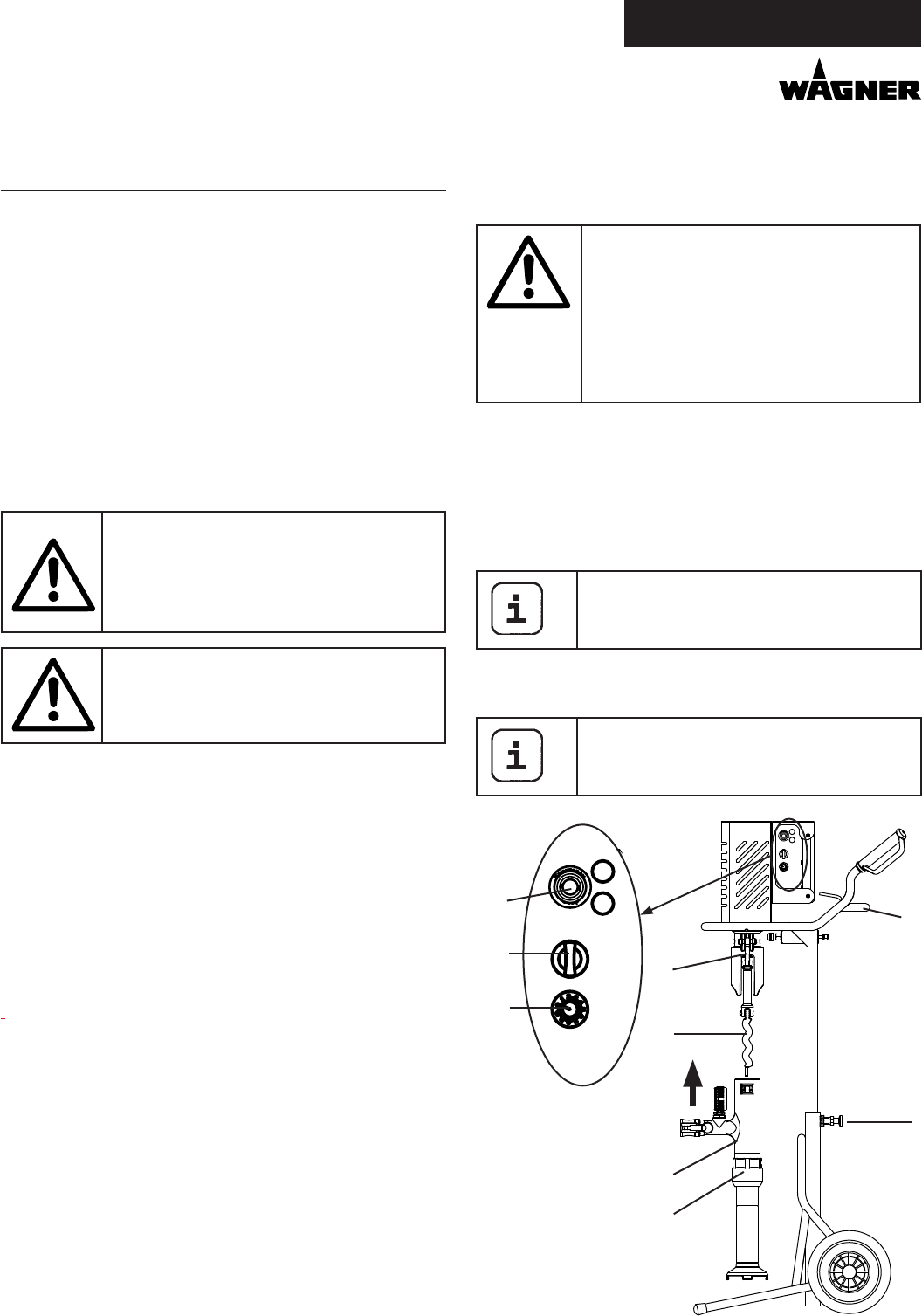

Pullsafetypin(1)toreartoreleaselock.PullPC430upbyits

frame (2) until the machine engages in the top position.

Sprayrotor(3)withasuitablepumplubricant(orderno.9992

824).

Moveselectorswitch(4)to“A”andsetdeliveryvolumecon-

troller (5) to „0“.

Connectmainsplugtomainspowersupply.

commIssIonIng

• Beforeconnectingtheunittothemainssupply,ensurethat

the line voltage matches that specied on the rating plate.

Min. wire cross-section 3 x 1.5 mm

2

. Unroll the

extension cable completely. Ensure that the

coupling pieces and plugs are free of dam-

age.

Laythedevicesupplycablesothatthereisno

danger of stumbling.

Protect against damage, for example against

being driven over.

6.1.1 CONNECTION TO MAINS POWER SUPPLY/

EXTENSION CABLE

Connection to the mains network only via a special feed-

ing point, for example via a distribution board for con-

struction sites, with residual current protective device

with INF ≤ 30 mA.

The operation light (6) shows operational readiness.

Fold locking pins (7) up towards the magnet holders in the

handletopreventthembeingtwistedduringassembly.

Only the person controlling the machine

may assemble the pump unit.

Never operate mortar spraying machine

with an exposed rotor.

Do not reach into the rotor when it is

moving. Risk of crushing.

Caution if you have long hair. Only wear

close-tting clothes at work.

Slide pump unit (8) over rotor (3) from below and press up-

wards.

Setdeliveryvolumecontroller(5)to1or2.

Set selector switch (4) to “F” to switch on pump. The pump unit

isautomaticallydrawnupbytherotor.

As soon as the pump unit is in its end position, fold the two

locking pins (7) down and use nuts to x the pump unit.

Ifnecessaryrotatepumpunit(8)byhandto

move locking pins (7) into end position.

Set selector switch (4) to “A” to switch o pump.

Disconnect mains plug.

After assembling the pump unit, secure the

union nut (9) on the pump unit, using the

specialkeytodoso.

A

F R

POWER

ERROR

4

6

2

1

3

A

F

R

POWER

ERROR

5

7

8

9