38

Plast Coat 430

GB

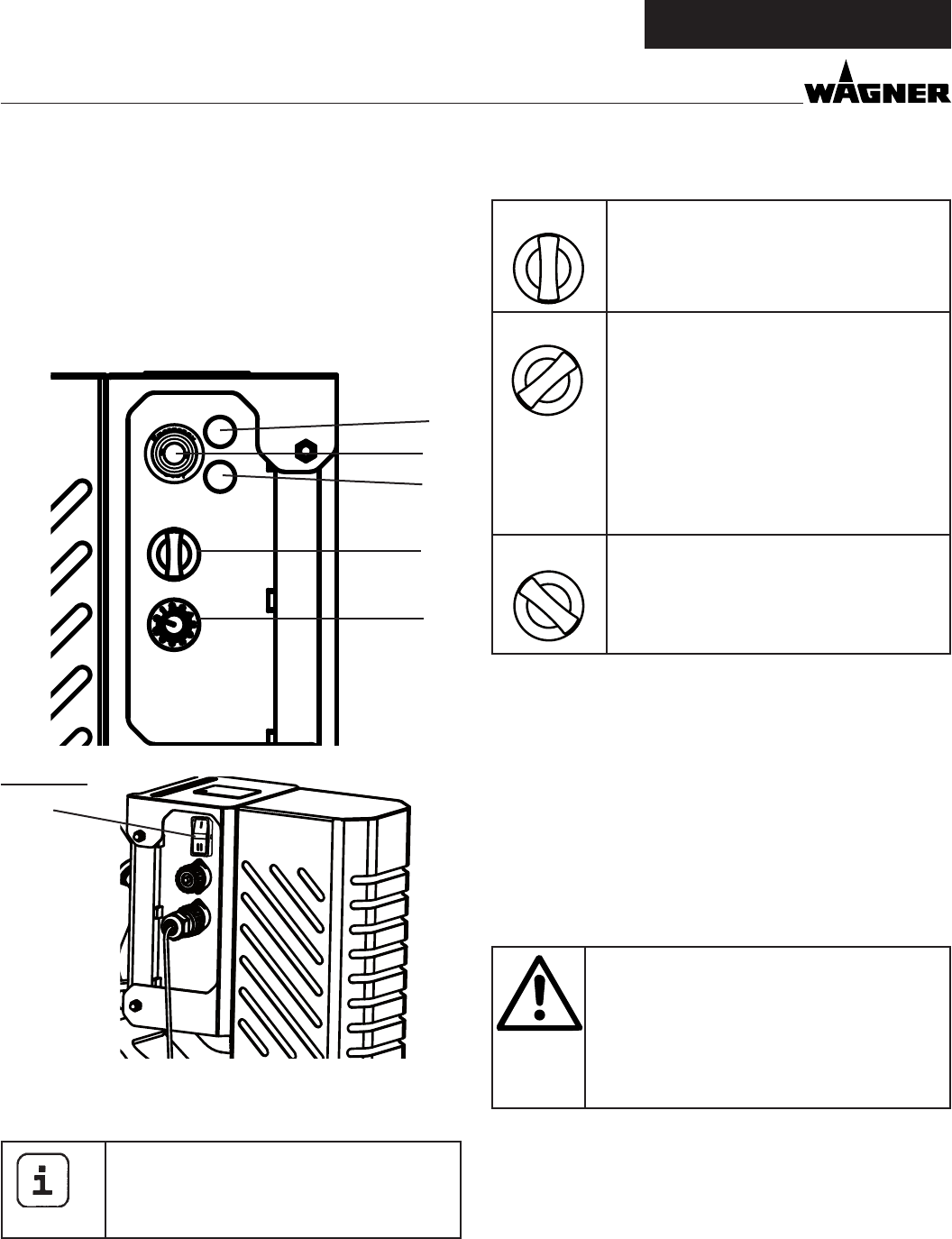

4.1 OPERATING ELEMENTS AND DISPLAYS ON

DEVICE

1 Deliveryvolumecontroller 0-10

2 Selector switch for operating mode

3 Indicator light (Error)

4 Operating light (Power)

5 EMERGENCY STOP switch

6 Switch for activating remote control

Thedeliveryvolumecontroller(Fig. 3, 1) is used to regulate

theconveycapacityfrom0-10smoothly.

Theremotecontrol(availableseparately,art.

no.2308417)canbeusedtoconveniently

controlthepump‘sdeliveryvolumefromthe

spraylance.

overvIew

The selector switch (Fig. 3, 2) oers the following modes:

A

R

F

“A” position = automatic

Basic setting for control with an automatic

spraylance,pneumaticspraylanceorre-

mote control

A

R

F

“F” position = manual activation

Switchesonthemortarsprayingmachine.

This setting is required for:

• suctionunitassembly

When using the pneumatic lance, this set-

ting is also needed for:

• pre-rinsing the mortar hose to improve

thematerial‘sabilitytoslide

• cleaning

A

R

F

“R” position = reverse gear (must be held in

this position).

This setting is required for:

• relievingpressureonthemortarhose

• suctionunitdisassembly

Detailed explanation of selector switch use:

If the selector switch is in the “A” position, the PC430 can be

switched on and o with the material shut-o on the auto-

maticorpneumaticspraylance.

Ifthereisnospraylancetted(e.g.:assembly/disassemblyof

suction unit), the machine is switched on using the “F” switch

position and o using the “A” position.

Since the air supply through the compressor needs to be

switched o to clean the mortar hose, the pneumatic lance

is not controlled using the material shut-o. In this case, the

machine must therefore also be switched on using the “F” po-

sition.

Important: control via the selector switch and

materialshut-oaretreatedequally.

The machine can be switched from the “A” po-

sition (control using material shut-o) to “F” at

anytime.

Wewouldthereforerecommendthatonlyone

person operate the machine.

The operating light (green, Fig. 3, 4) indicates that the machine

isenergisedandready.

The indicator light (red, Fig. 3, 3) indicates a fault. For detailed

information about this kind of fault, refer to the „Rectication

of faults“ section on page 50.

The switch(Fig.3, 6)allowsyou toswitchbetweeninternal

and external control. In Position “I“, the PC 430 is controlled

with the integrated control panel. In Position “II” it is controlled

with the remote control.

2

A

F R

POWER

ERROR

1

4

3

Rear view

6

5