Page 36

iQ Series, Ultrasonic Hand Held Systems User’s Manual

Dukane Manual Part No. 403-577-01

Theory of Operation

Plastic welding is the most common application of

ultrasonic assembly. To perform ultrasonic plastic

welding, the vibrating tip is brought into contact with

one of the work pieces. Pressure is applied and ultrasonic

energy travels through the material generating frictional

heat at the contact point of the two parts. The frictional

heat melts a molded ridge of plastic on one of the pieces

and the molten material ows between the two surfaces.

When the vibration stops, the material solidies forming a

permanent bond.

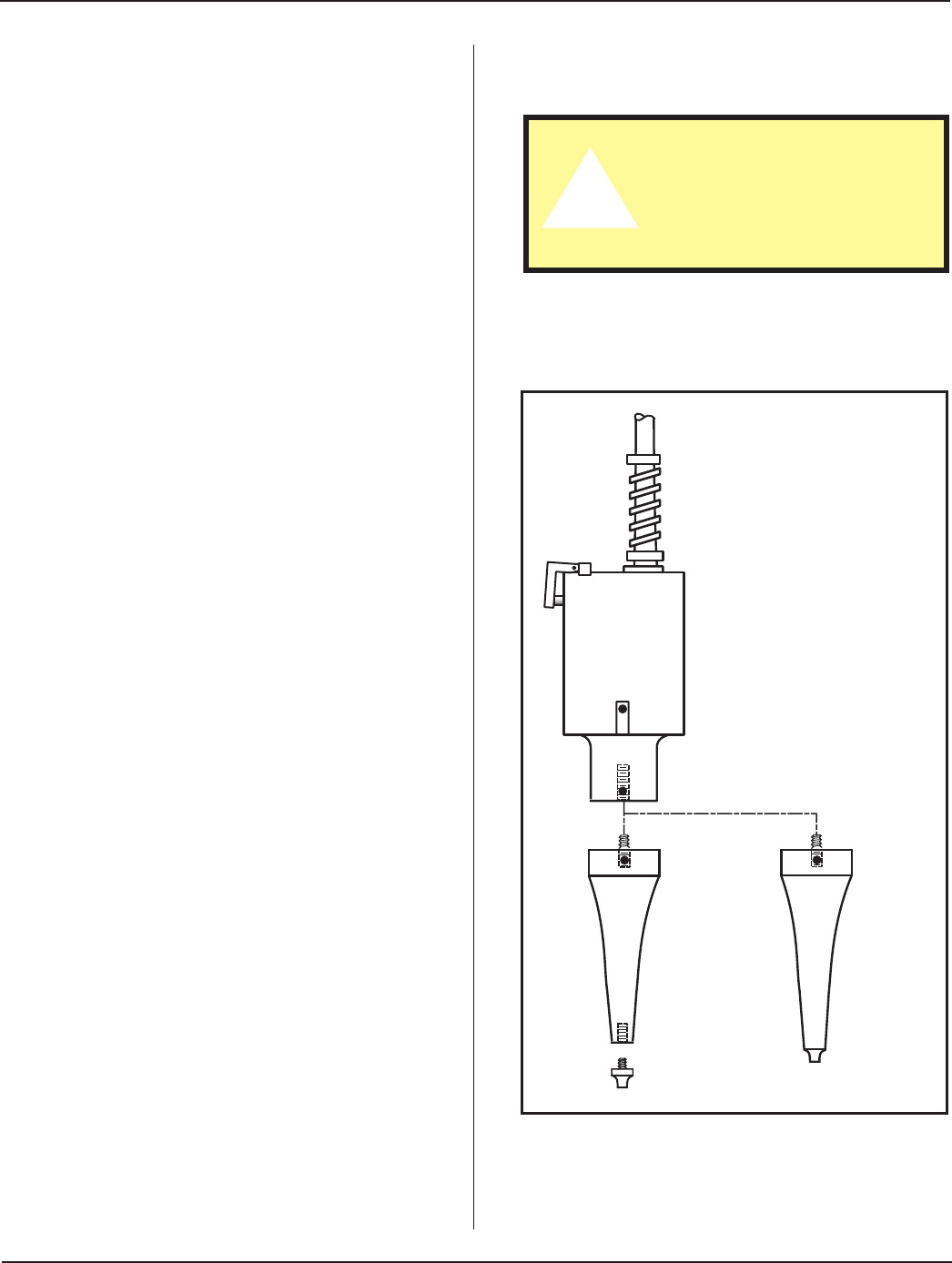

Probe Conguration

A basic ultrasonic probe package consists of:

1. A probe which houses the transducer to convert the elec-

trical energy supplied by the generator into mechanical

vibrations.

2. A horn to transfer the mechanical vibrations from the

probe to the parts to be welded.

Optional components include special replaceable tips

which can be threaded on to the tip of the horn, and a

booster to amplify the mechanical vibrations of the horn.

A basic hand–held probe system is shown in Figure 6-2.

The hand probe is easily identied by its trigger actuator

and permanently attached cable. Normally a booster is not

used with a hand probe as this increases the length and

weight and reduces its versatility. The optional threaded

titanium tip can be used when the application calls for

a staking prole or a pointed spot weld. Replaceable

tips are not commonly used in high–volume production

environments.

Standard

Horn

Hand

Probe

Tip

Custom

Horn

Figure 6–2 Hand Probe, Horn and Tip

CAUTION

Never use the hand probe if

the cable insulating jacket is

cut or damaged in any way.