Page 40

iQ Series, Ultrasonic Hand Held Systems User’s Manual

Dukane Manual Part No. 403-577-01

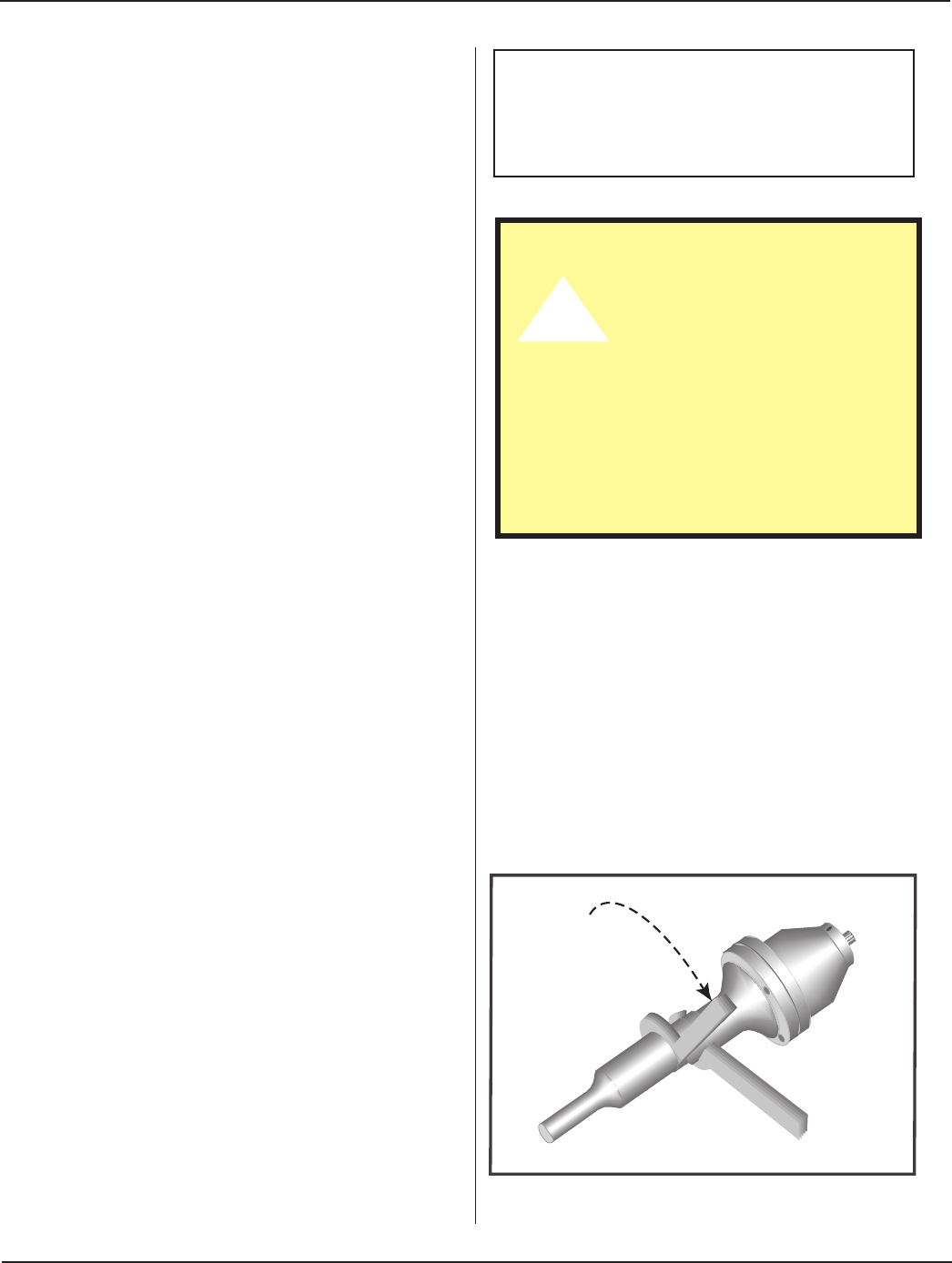

Attaching The Horn to

a Booster, Booster to a

Probe, or Horn to a Probe

1. Inspect all surfaces to be joined for stress cracks,

chips, or gouges. Any of these irregularities will affect

operation and could lead to further equipment damage.

Contact the Dukane Ultrasonic Tooling Department

concerning a damaged booster.

2. Ensure that the mating surfaces of the two components

are clean and smooth. These surfaces must make inti-

mate contact for the mechanical energy to pass from

one component to the next. Pitting or a buildup of old

grease and dirt on a mating surface will interfere with

the energy transfer and reduce the power delivered.

3. Make sure that the stud in the horn or booster is tight.

See the preceding mounting stud assembly instructions

for torque specications.

4. Remove any foreign matter from the threaded stud and

mating hole.

5. Apply an extremely thin layer of a high temperature,

high pressure silicon grease to the surface that mates

with the horn. The grease will allow both surfaces to

intimately mate and become acoustically transparent

which improves the energy transfer. We recommend

Dow–Corning #4 (or #111 as an alternate). A small

packet of Dow–Corning #4 is supplied with the system.

If you cannot use a silicon–based grease in your facility,

a petroleum–based grease may be used. However, it is

likely to leave carbonaceous deposits on the surface,

and require more frequent joint maintenance. Grease

may be omitted if mylar washers are preferred on sys-

tems that require frequent changes. Mylar is plastic and

will creep under compression, so mylar is not recom-

mended for system that are not changed frequently.

Failure to follow these instructions, may result in the

mating surfaces bonding and difculty removing the

horn from the booster or the booster from the probe.

Figure 6–5 Stack Assembly Procedure

Tighten

CAUTION

Never leave a horn or booster

assembly hand tight. Torque

it to the proper specications

before proceeding. If the as-

sembly is installed without

being properly torqued down,

the assembly may vibrate

severely, damaging the mat-

ing surfaces and causing

the generator to overload.

NOTE

Always remove a probe stack from the

machine in which it is mounted before

attaching or removing a horn.