G0451 14" Sliding Table Saw

-47-

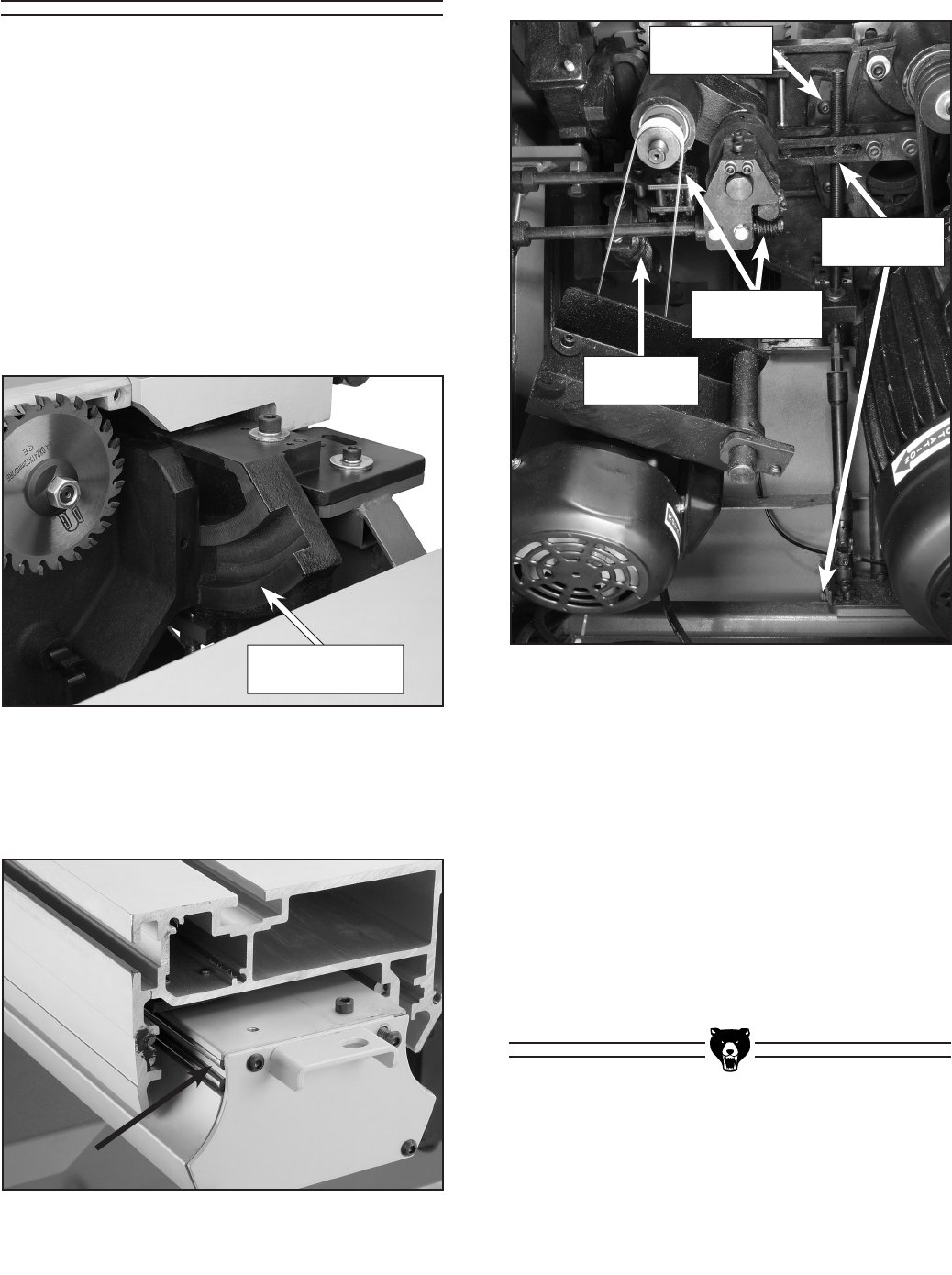

Lubrication

The bearings are sealed and pre-lubricated and

require no lubrication during their usable life.

However, your saw components will operate

at their best if the bearing surfaces are kept

clean—this is especially important for the trun

-

nion bearings.

Lubricate the areas indicated below every 6-12

months, depending on frequency of use.

1. Blade angling trunnions. These should be

lubricated with 6 or 7 drops of light machine

oil (see

Figure 87).

2. Sliding table ways. Spray or wipe on a light

machine oil such as WD-40

®

the entire length

of the steel rods (see

Figure 88).

Figure 87. Blade angling trunnions.

3. Scoring blade worm gears. Lubricate with

an automotive wheel bearing grease.

Blade Angling

Trunnion

Figure 88. Sliding table ways.

4. Blade height linkage. Lubricate with an

automotive wheel bearing grease.

5. Blade height bearing (Hidden behind the

motor in Figure 89). Lubricate with an auto-

motive wheel bearing grease in a grease

gun.

6. Blade tilt worm gear. Lubricate with an

automotive wheel bearing grease.

7. Blade height slide. Lubricate with an auto

-

motive wheel bearing grease.

Figure 89. Gear lubrication.

Blade Height

Slide

Scoring Blade

Worm Gears

Blade Height

Linkage

Blade Tilt

Worm Gear