-22-

G0646/G0647 50/65 Ton Ironworker

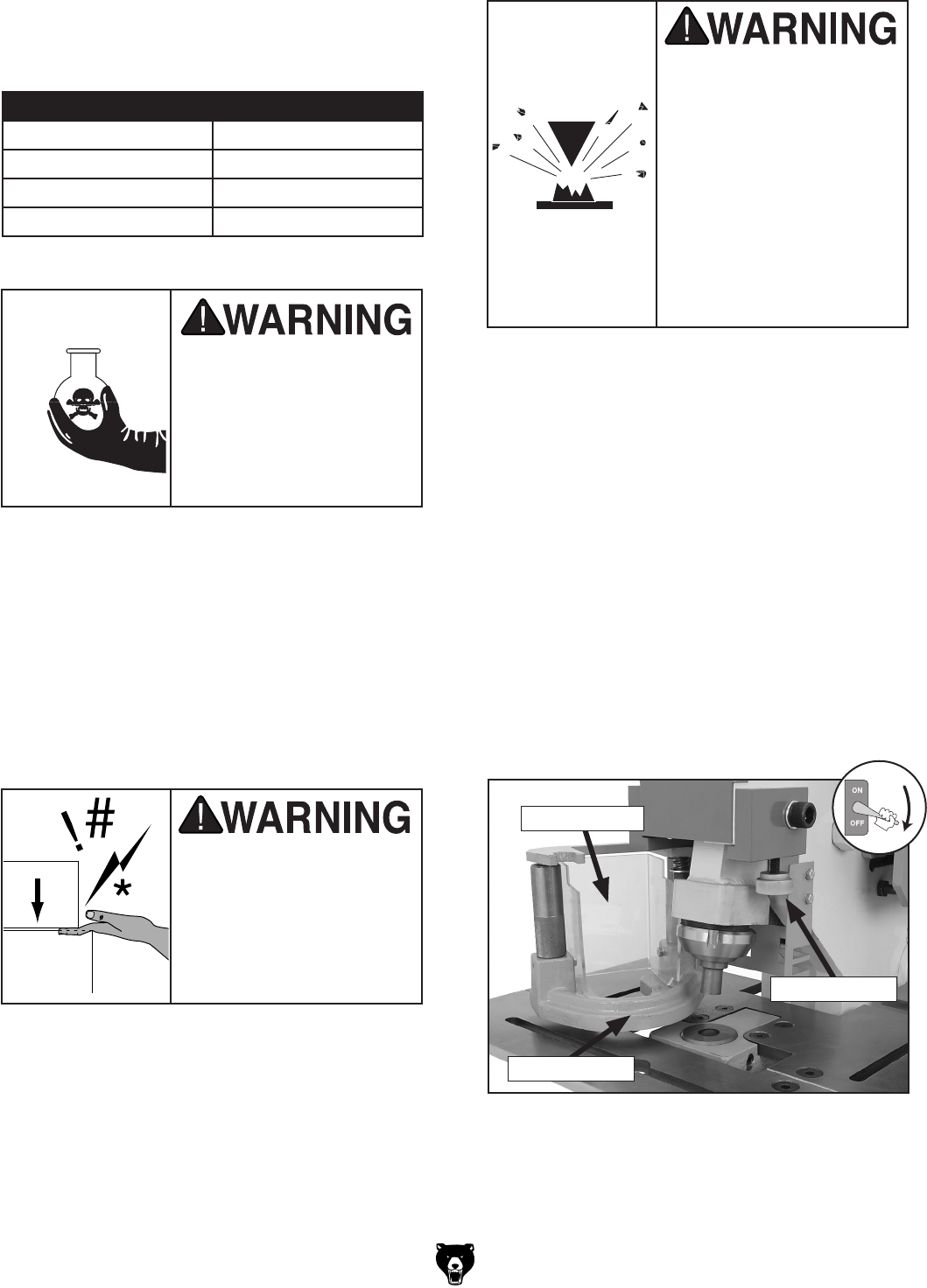

3. Brush one of the lubricants from Figure 18 or

an equivalent onto the punch, die, and both

sides of the workpiece.

Brand Type

B.P. Servora 68

Castrol Ilobroach 219

Duckhams Adfornal EP7

Shell Garia 927

Figure 18. Recommended cutting lubricants.

workpiece lubricants

4. Position the workpiece under the punch and

secure it in position with the table guides.

5. Set the controls to Punch and Normal,

then use the foot actuator to punch the

workpiece.

Note: When the punching operation is com-

plete, the punch will automatically raise up

out of the workpiece.

The force of this ironwork-

er can quickly smash or

remove fingers or hands.

Always keep clear of all

cutting stations before

using the foot actuator to

begin the operation.

Tooling and workpiece

could break apart under

pressure, sending metal

debris toward the opera

-

tor at a high rate of speed.

Always keep all safety

guards and access panels

in the correct position and

secured when perform-

ing cutting operations

to reduce the risk of this

hazard.

Removing/Installing Punch Tooling

Tools Needed Qty

Hex Wrench 6mm ..............................................

1

Spanner Wrench (included) ...............................

1

To remove punch tooling:

1. Set the controls to Notch and Inch, use the

foot actuator to raise the punch to the upper

-

most position, then stop the motor.

2. DISCONNECT MACHINE FROM POWER!

3. Loosen the knurled knob securing the right

side of the stripper and safety guard assem

-

bly, then swing it away from the punch and

die, as shown in

Figure 19.

Figure 19. Punch stripper and safety guard

assembly positioned away from the punch and

die.

Safety Guard

Stripper Base

Knurled Knob

Poison Hazard! Use prop-

er protection equipment

when handling cutting

fluid and

only dispose by

following

federal, state,

and fluid

manufacturer

requirements

.