40

Chapter 3 - Preparations

3-2. Cutter Installation Method 1 (With Nose Unit)

3. Cutter Installation and Alignment

10

Lower the spindle until the tip of the nose unit

touches the table.

When the nose touches the table, operation stops auto-

matically.

11

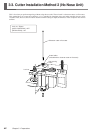

Insert the cutter (diameter 4.36 mm), then bring

the tip lightly into contact with the table.

When you insert the cutter, orient it so that it will not

catch on the collet.

12

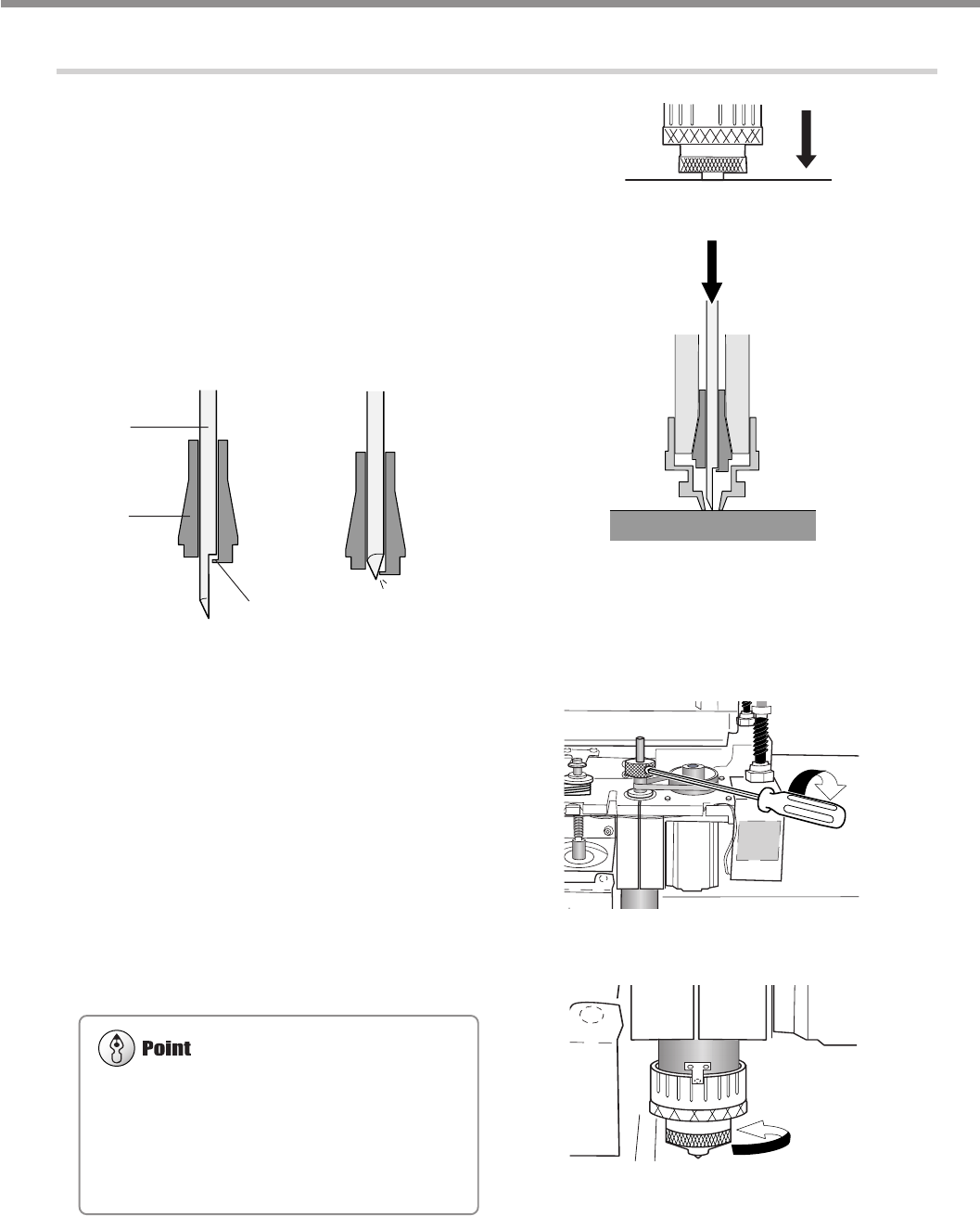

Use the included hexagonal screwdriver to

tighten the tool securing screw. Raise the

spindle.

13

Tighten the nose unit by 4 to 8 ticks on the scale.

The amount you tighten the nose unit determines the

cutting-in depth. Adjust it to suit the task. An amount

of 4 to 8 scale ticks corresponds to 0.1 to 0.2 mm (0.004

to 0.008 in.). One scale tick is 0.0254 mm (0.001 in.),

and one full turn is 25 scale ticks, or 0.635 mm (0.025

in.).

Stopper

Cutter

Collet

Yes No