V300-PRO

INSTALLATION

A-6 A-6

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTPUT CABLES

Select the output cable size based upon the following

chart.

Cable sizes for Combined Length of Electrode and

Work Cable (Copper) 75° rated:

Duty Length Up 61-76m

Cycle Current 61m (200 ft.) (200-250 ft.)

100% 250 1/0 1/0

60% 300 1/0 2/0

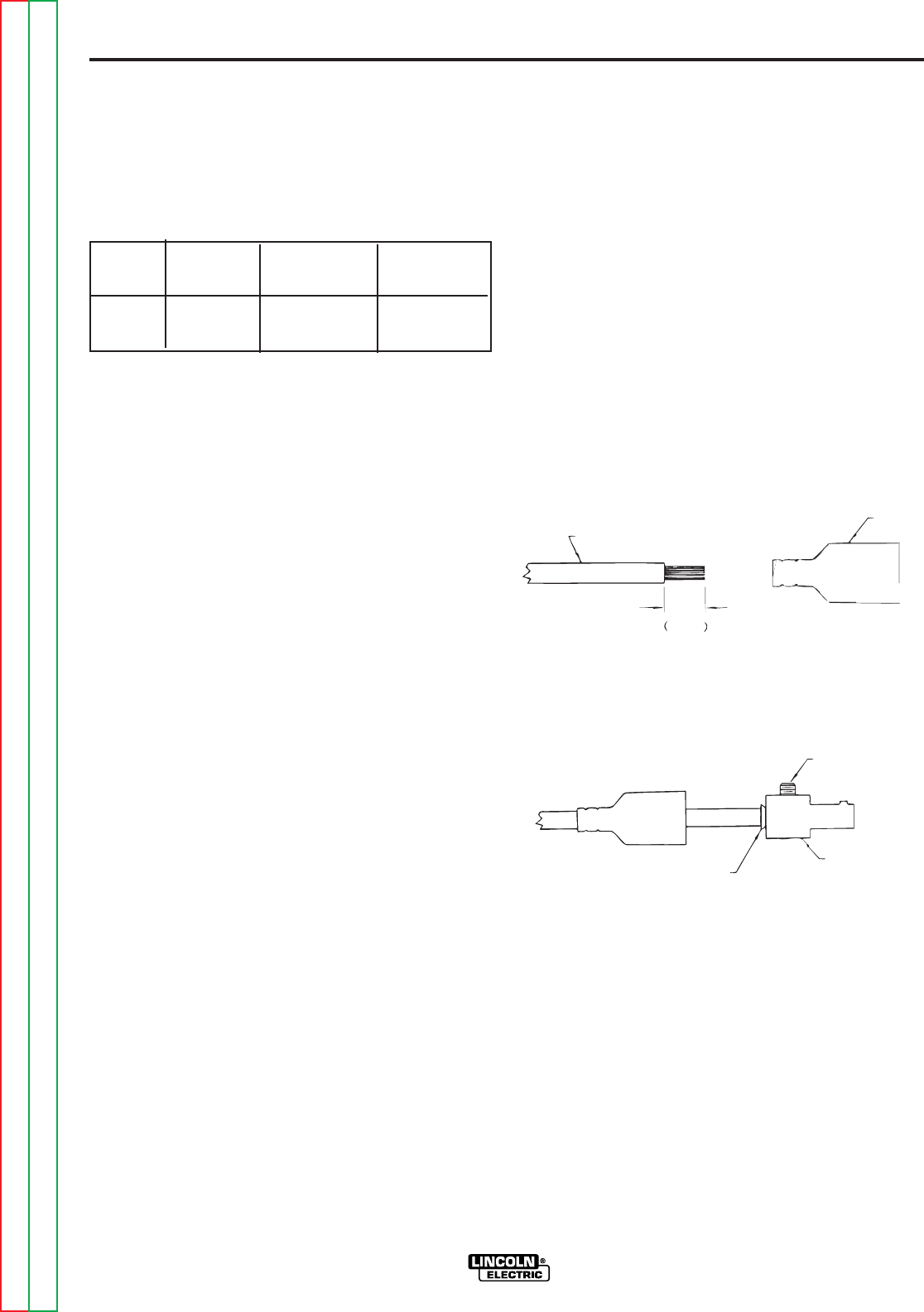

QUICK DISCONNECT PLUGS (K852-7)

A quick disconnect system is used for the welding

cable connections. The welding plug included with the

machine is designed to accept a welding cable size of

1/0 to 2/0.

1. Remove 1 inch (25mm) of welding cable insulation.

2. Slide rubber boot on to the cable end. The boot

end may be trimmed to match the cable diameter.

Soap or other lubricant will help to slide the boot

over the cable.

3. Slide the copper tube into the brass plug.

4. Insert the cable into the copper tube.

5. Tighten set screw to collapse copper tube. The

screw must apply pressure against welding cable.

The top of the set screw will be well below the sur-

face of the brass plug after tightening.

6. Slide the rubber boot over the brass plug. The rub-

ber boot must be positioned to completely cover all

electrical surfaces after the plug is locked into the

receptacle.

25 mm

1 in.

WELDING CABLE

BOOT

TRIM

SET SCREW

BRASS PLUG

COPPER TUBE

reverse 25mm & 1in