DIAGRAMS

G-4 G-4

RANGER 8

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

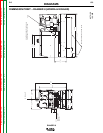

CONNECTION OF RANGER 8 TO LN-7 & K240 CONTACTOR KIT

WARNING: Turn the power off when making connections.

N.A. Use power source polarity switch to set for desired elec-

trode polarity. Position the output selector switch on the

power source to the CV position.

N.B. 3 conductor #16 power cord physically suitable for the

installation and plug rated at 115 volts 15 amperes AC.

N.C. Plug into 115 volt AC receptacle on welder control panel or

other 115 volt AC supply rated at a minimum of 500 volt-

amperes.

N.D. Leads #21 and GND do not appear on LN-7’s with codes

below 7026.

N.E. Welding cables must be of proper capacity for the current

and duty cycle of immediate and future applications.

N.F. If LN-7 is equipped with a meter kit, extend lead #21 using

#14 or larger insulated wire physically suitable for the

GND. 32 2 4 31

TO LN-7

32

2

4

31

POWER

SOURCE

AUTO.

EQUIP.

WORK

ELECTRODE

POWER

SOURCE

75

76

77

K240 CONTACTOR KIT

21

115V (50/60HZ.)

(NOTE : 600 AMP CAPACITY)

ELECTRODE CABLE TO LN-7

TO WORK

CONTROL CABLE

CONNECT THE CONTROL CABLE

GROUND LEAD TO THE FRAME

THE TERMINAL STRIP OR TO

AN UNPAINTED FRAME SCREW.

N.D.

N.J.

N.F. & N.G.

N.B.

N.C.

TERMINAL MARKED NEAR

CONNECTION OF LN-7 & K240 CONTACTOR KIT WITH 115 VOLT AC AUXILIARY POWER AND CV OUTPUT

WELDER STANDARD OUTPUT TERMINALS

S17742

10-2-92

installation. An S16586-”length” remote voltage sensing

work lead may be ordered for this purpose. Connect it

directly to the work piece independent of the welding work

cable. For convenience, this extended #21 lead should be

taped to the welding work lead.

N.G. Tape up bolted connection where lead #21 is extended.

N.H. Idler switch on power source must be in high idle position.

N.J. If an optional remote output control is used, connect it to

this terminal strip or 6 pin Amphenol receptacle. NOTE:

Terminal strip or 6 pin Amphenol receptacle not available

on all power sources.

CAUTION: Any speed up of the engine RPM by changing the

governor setting or over-riding the throttle linkage will

cause an increase in the AC auxiliary voltage. If this volt-

age goes above 140 volts, the LN-7 control circuit will be

damaged. The engine governor setting is pre-set at the

factory - do not adjust above RPM specifications listed in

engine welder operating manual.

M17486

ELECTRODE CABLE

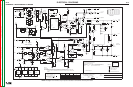

LN-25

WIRE FEEDER

REMOTE CONTROL

TO WORK

ELECTRODE

N.A. WELDING CABLE MUST BE SIZED FOR CURRENT AND DUTY CYCLE OF APPLICATION.

TO WORK

WORK CLIP LEAD

TO WORK

6 PIN

AMPHENOL

N.C. IF OPTIONAL REMOTE OUTPUT CONTROL IS USED, PLACE OUTPUT CONTROL SWITCH

IN "OUTPUT CONTROL REMOTE" POSITION.

RANGER 8 / LN-25 ACROSS THE ARC CONNECTION DIAGRAM

CRM 21883

OPTIONAL K444-1

N.B. USE POLARITY SWITCH TO SET FOR DESIRED ELECTRODE POLARITY. POSITION THE OUTPUT SELECTOR

SWITCH TO THE WIRE FEED (CV) POSITION.

WARNING

Do not operate with panels open.

Disconnect NEGATIVE (-) BATTERY LEAD

before servicing.

Do not touch electrically live parts.

Keep guards in place.

Keep away from moving parts.

Only qualified personnel should install,use

or service this equipment.