OPERATION

B-5 B-5

RANGER 8

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Welding Process

Stick (Constant Current) Welding

Connect welding cables to the "TO WORK” and

"ELECTRODE” studs. Start the engine. Set the

"Polarity” switch to the desired polarity. Set the

“RANGE” switch to a setting that is equal to or slightly

greater than the desired welding current. (The

“RANGE” dial marking indicates the maximum

current

for that range). Fine adjustment of the welding current

is made by adjusting the output “CONTROL” or remote

control. For best arc stability, use settings 5

through 10.

The Ranger 8 can be used with a broad range of AC

and DC stick electrodes. See “Welding Tips 1” includ-

ed with the Ranger 8 for electrodes within the rating of

this unit and recommended welding currents of each.

TIG (Constant Current) Welding

The K930-[ ] TIG Module installed on a Ranger 8 pro-

vides high frequency and shielding gas control for AC

and DC GTAW (TIG) welding processes. The TIG

Module allows full range output control. Afterflow time

is adjustable from 0 to 55 seconds.

When using the Ranger 8 for AC TIG welding of alu-

minum, the following settings and electrodes are

recommended:

The K930-[ ] TIG Module should be used with the

Ranger 8 on high idle to maintain satisfactory opera-

tion. It can be used in the AUTO position but the delay

going to flow idle after welding is ceased will be

increased if the AFTERFLOW CONTROL is set above

10 seconds.

Wire Feed Welding Processes

(Constant Voltage)

The only Innershield

®

electrode recommended for use

with the Ranger 8 is NR

®

-211-MP. The electrode sizes

and welding ranges that can be used with the Ranger

8 are shown in the following table:

The Ranger 8 is recommended for limited “MIG” weld-

ing (GMAW - gas metal arc welding). The recom-

mended electrodes are .030” and .035” L-50 and L-56.

They must be used with a blended shielding gas such

as C25 (75% Argon - 25% CO

2

). The welding ranges

that can be used with the Ranger 8 are shown in the

following table:

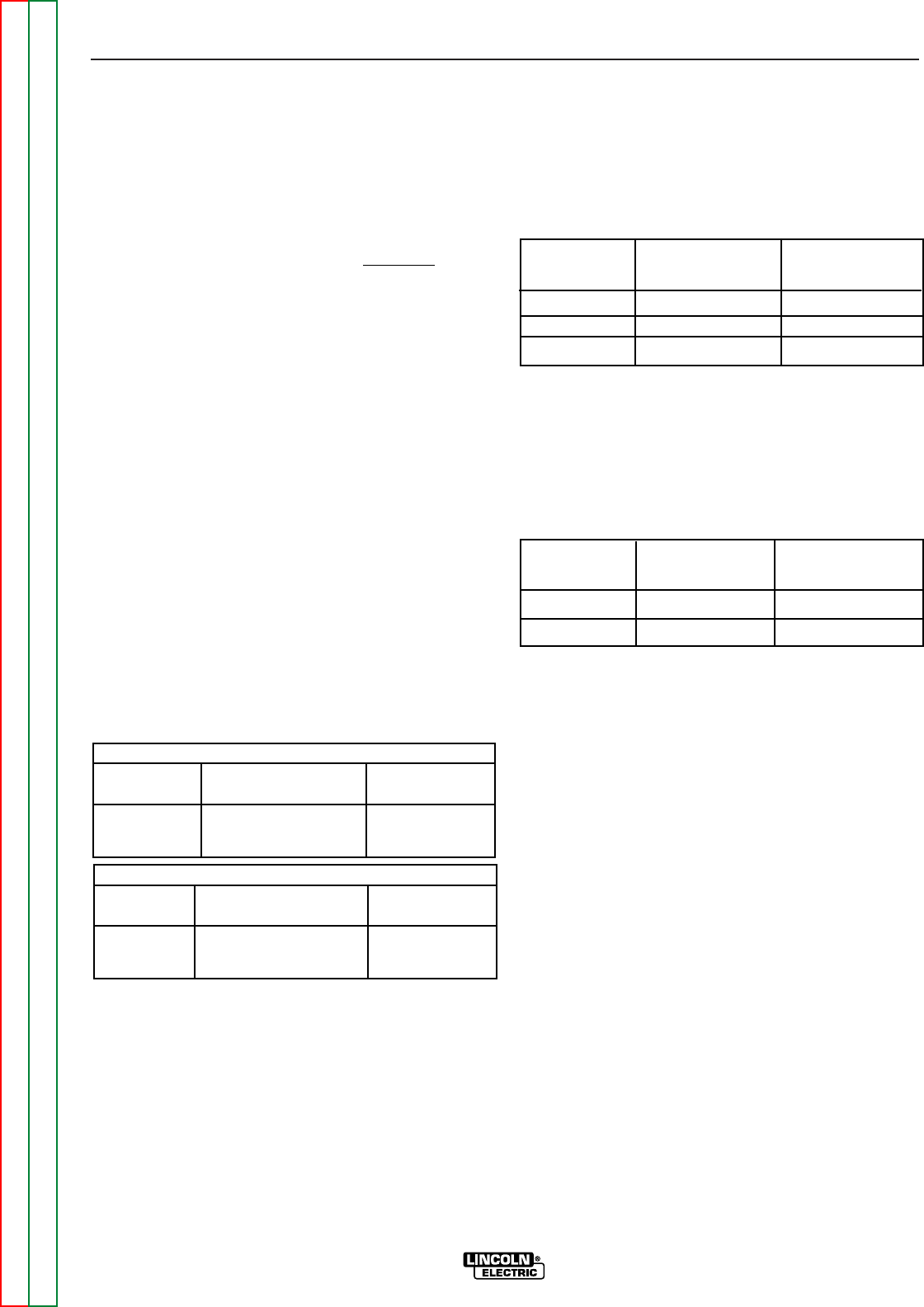

SETTINGS FOR 1% THORIATED TUNGSTEN

TUNGSTEN RANGE SWITCH APPROXIMATE

DIAMETER (in.) SETTINGS CURRENT RANGE

1/8 70, 90, 125, or 175 80 - 225 Amps

3/32 50, 70, 90, or 125 50 - 180 Amps

1/16 50, 70, or 90 45 - 120 Amps

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.035 80 - 110 75A to 120A

.045 70 - 130 120A to 170A

.068 40 - 90 125A to 210A

Diameter Wire Speed Approximate

(in.) Range In./Min. Current Range

.030 80 - 110 75A to 120A

.035 70 - 130 120A to 170A

SETTINGS FOR PURE TUNGSTEN

TUNGSTEN RANGE SWITCH APPROXIMATE

DIAMETER (in.) SETTINGS CURRENT RANGE

1/8 70, 90, or 125 80 - 150 Amps

3/32 50, 70, or 90 45 - 130 Amps

1/16 50, or 70 40 - 80 Amps