Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-5 F-5

RANGER 8

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-800-833-9353 (WELD).

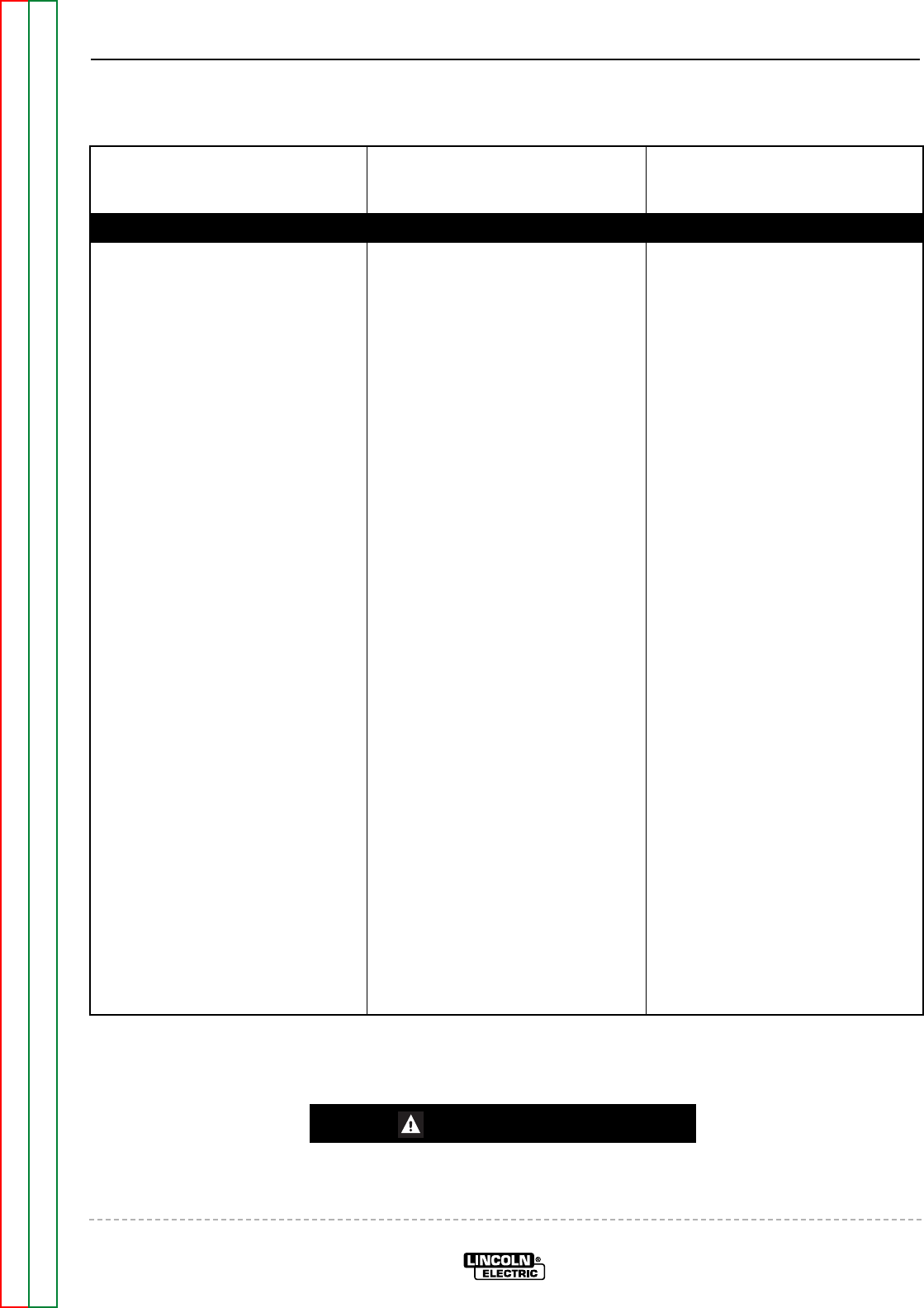

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

No weld output, the auxiliary

power (230-115VAC) is operating

normally. Engine runs normally.

1. Check the open circuit voltage

(OCV) at the welder output ter-

minals, engine at high idle (3650

RPM). Normal maximum is 73

to 80VAC. Normal DC maxi-

mum is 67 to 72VDC. If the

OCV is OK then proceed to

Step #2. If the OCV is not pre-

sent at the welder output termi-

nals, contact your local Lincoln

Authorized Field Service

Facility.

2. Check the welding cables,

clamps and electrode holder for

loose or broken connections.

1. Disconnect lead W1 from the

Output Bridge (D1) and check

for the presence of 80VAC from

lead W1 to lead W2 on the main

stator winding. See wiring dia-

gram. If the AC voltage is NOT

present, the winding in the sta-

tor may be faulty. Check the

winding for continuity and test

to be sure it is NOT grounded to

the stator iron. Replace if nec-

essary. If the correct AC volt-

age is present, proceed to step

#2.

2. Check the Reactor, Range

Switch (S1) and associated

wires for loose or faulty connec-

tions. Check the reactor wind-

ing for continuity and test to be

sure it is NOT grounded to the

reactor iron.

3. Check the Choke (L1), Polarity

Switch (S2) and associated

wires for loose or faulty connec-

tions. Check the choke winding

for continuity and test to be

sure it is NOT grounded to the

choke iron.

4. Check the weld output termi-

nals and associated wires for

loose or faulty connections.

5. Perform the Output Bridge Test.