OPERATION

B-4 B-4

CLASSIC I

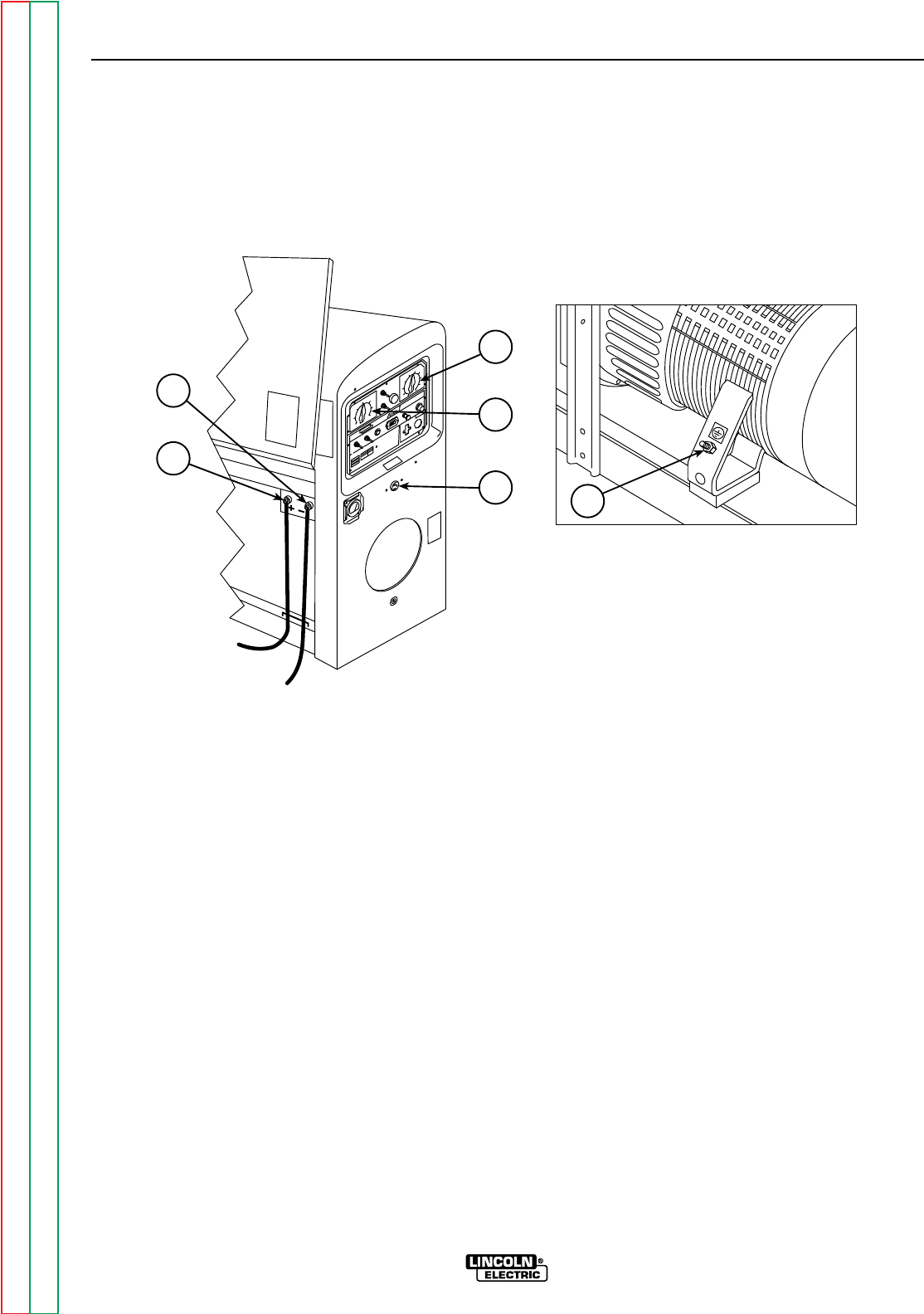

FIGURE B.1 – OUTPUT CONTROLS

1. CURRENT RANGE SELECTOR

2. FINE CURRENT ADJUSTMENT

3. 115 VOLT DC RECEPTACLE

4. WELD OUTPUT TERMINAL (–)

5. WELD OUTPUT TERMINAL (+)

6. GROUND STUD

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following features:

1. CURRENT RANGE SELECTOR: Selects ranges

of continuous current output for constant current

stick or TIG applications and constant voltage wire

feed applications (with optional Wire Feed Module).

See

Control of Welding Current

for more informa-

tion.

2. FINE CURRENT ADJUSTMENT: Allows fine

adjustment of current within the selected output

range. See

Control of Welding Current

for more

information.

3. 120 VOLT DC RECEPTACLE: Connection point for

supplying 120V DC power to operate DC electrical

devices.

4. WELD OUTPUT TERMINAL (–) WITH FLANGE

NUT: Provides the connection point for either the

electrode holder or the work cable.

5. WELD OUTPUT TERMINAL (+) WITH FLANGE

NUT: Provides the connection point for either the

electrode holder or the work cable.

6. GROUND STUD: Provides a connection point for

connecting the machine case to earth ground. See

Machine Grounding

in the

Installation

section of

this manual.

CONTROLS AND SETTINGS

The welder/generator controls are located on the

Output Control Panel of the machine case front.

E

ngine idler control and start/stop controls are also on

the case front. Welding output terminals and ground

stud are located on the machine right side, under the

door. See Figure B.1, B.2 and B.3 and the explanations

that follow.

6

3

5

4

2

1

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC