TROUBLESHOOTING & REPAIR

F-10 F-10

CLASSIC I

Observe Safety Guidelines

TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed.

Call 1-800-833-9353.

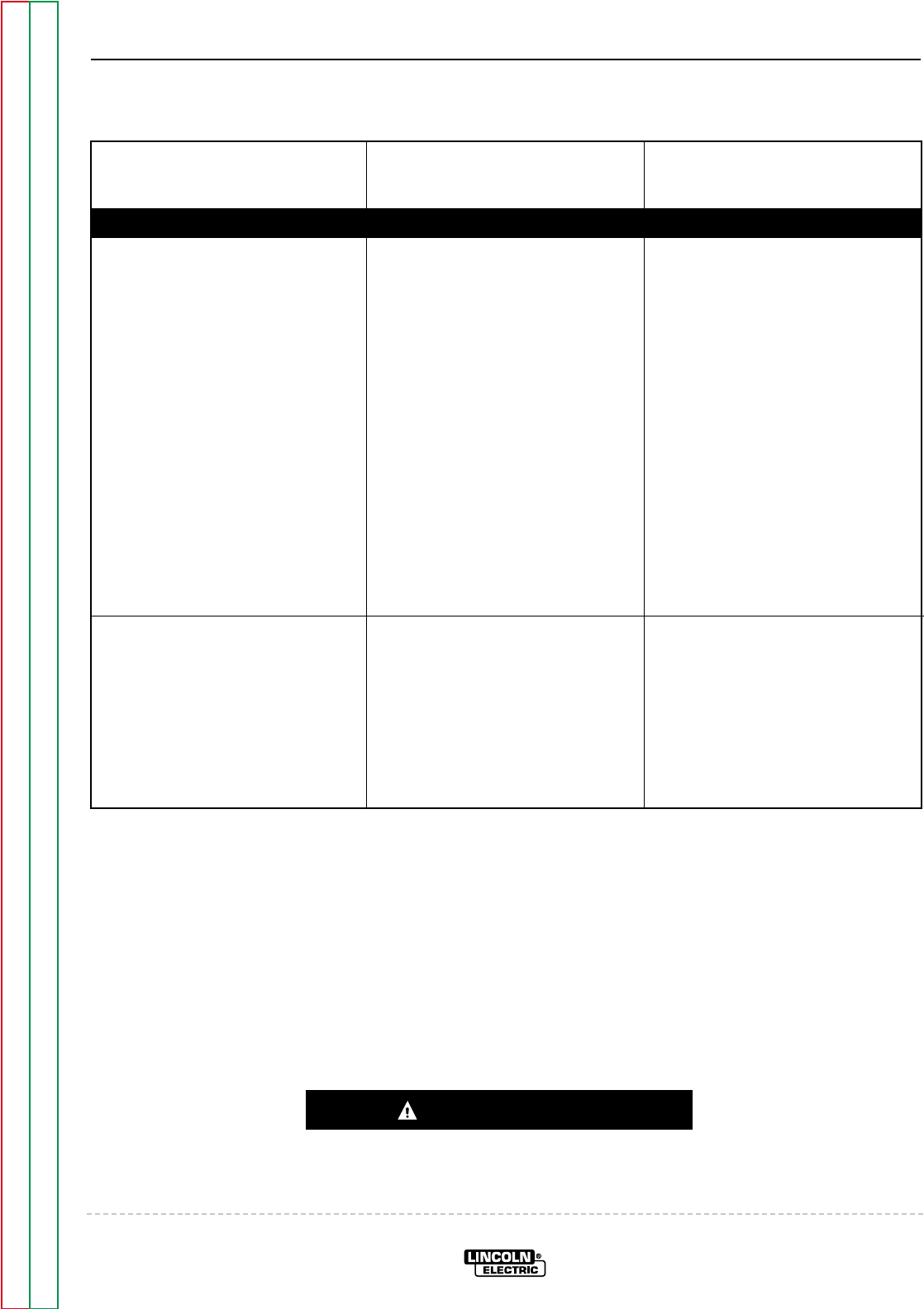

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

FUNCTION PROBLEMS

The engine will NOT go to high

speed when a load is applied to the

welding output terminals. The

engine does go to high speed when

a load is applied to the DC auxiliary

power receptacle.

1. Check welding cables for loose

or faulty connections.

1. Check the reed switch (CR2) for

proper operation. The reed

switch should close when there

is current flow in the welding cir-

cuit.

2. Locate the red lead connected

to the idler PC board. While

leaving the red lead connected,

jumper the red lead to frame

ground. If the engine goes to

high speed, the fault is in the

reed switch or associated leads.

See the Wiring Diagram.

3. If the engine does NOT go to

high speed (in step 2), the idler

PC board may be faulty.

The engine will NOT go to high

speed when a load is applied to the

DC auxiliary receptacle. The

engine does go to high speed when

a load is applied to the welding out-

put terminals.

1. Check the auxiliary power plug

and associated leads for loose

or faulty connections.

2. The load may be too small. The

load must be above 150 watts.

1. Check the black “B” leads con-

nected to the idler PC board and

associated connections. See

the Wiring Diagram.

2. The idler PC board may be

faulty.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC