TROUBLESHOOTING & REPAIR

F-6 F-6

CLASSIC I

Observe Safety Guidelines

TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed.

Call 1-800-833-9353.

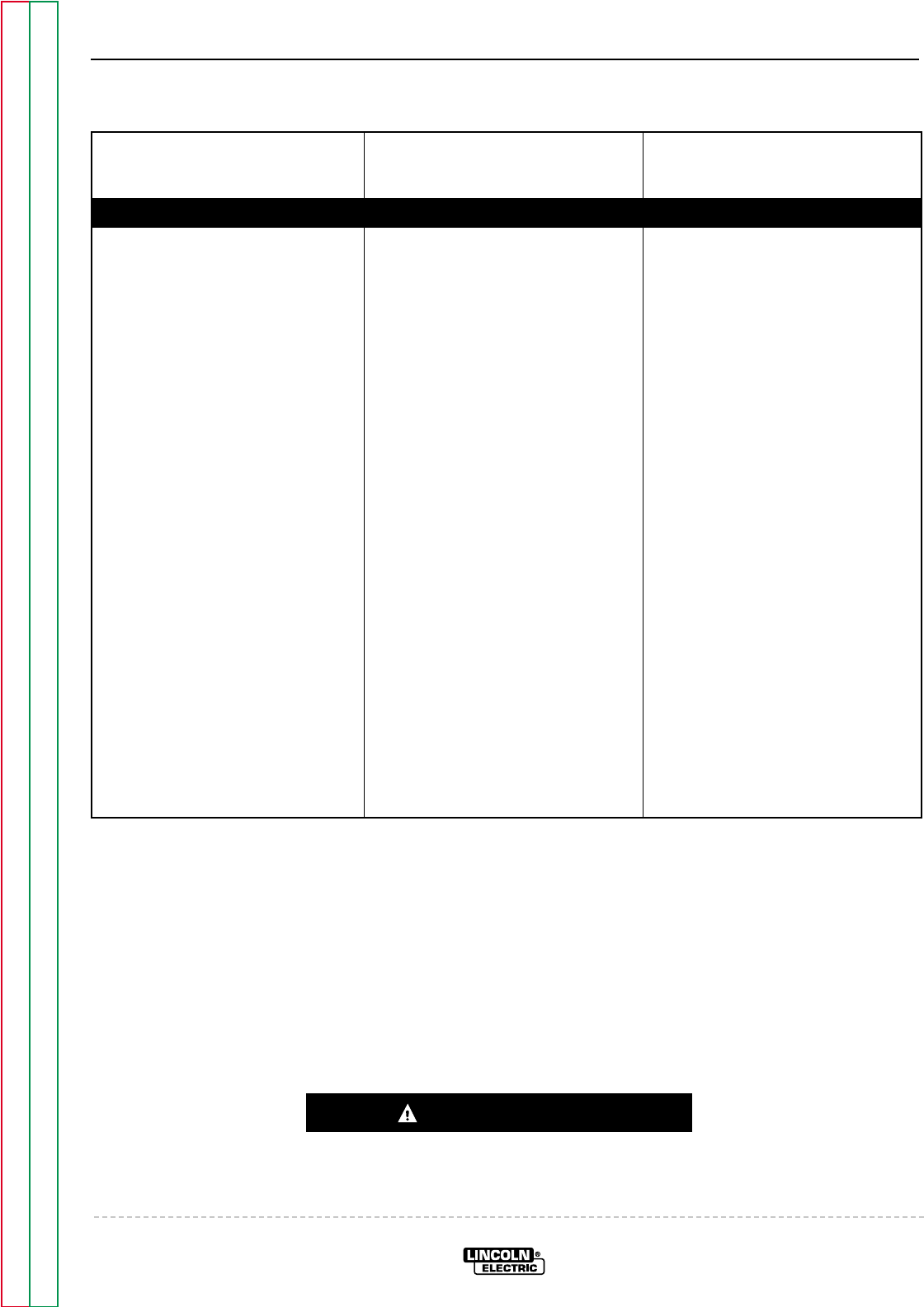

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

The welding output varies abnor-

mally. The auxiliary output remains

constant. The engine is operating

correctly.

1. Check for loose or faulty weld-

ing cables.

2. This may be a normal condition.

The machine will normally lose

some output as the components

are heated.

3. Check for loose, worn, dirty or

poorly seated main DC genera-

tor brushes.

4. The main armature commutator

may need cleaning.

1. Check the fine current control

field rheostat for resistance and

proper operation. Normal resis-

tance is 64 ohms. Check asso-

ciated wires for loose or faulty

connections. See the Wiring

Diagram.

2. Perform the Main Generator

Shunt Field Winding Test.

3. Check the current range

selector switch and contacts for

proper operation.

4. While the machine is loaded,

check the interpole and series

coils for signs of “arcing.” This

condition would indicate short-

ed turns in the “arcing” coil.

5. The main armature may be

faulty. Check for grounds.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC