F-15

TROUBLESHOOTING AND REPAIR

F-15

LN-10

Observe all Safety Guidelines detailed throughout this manual.

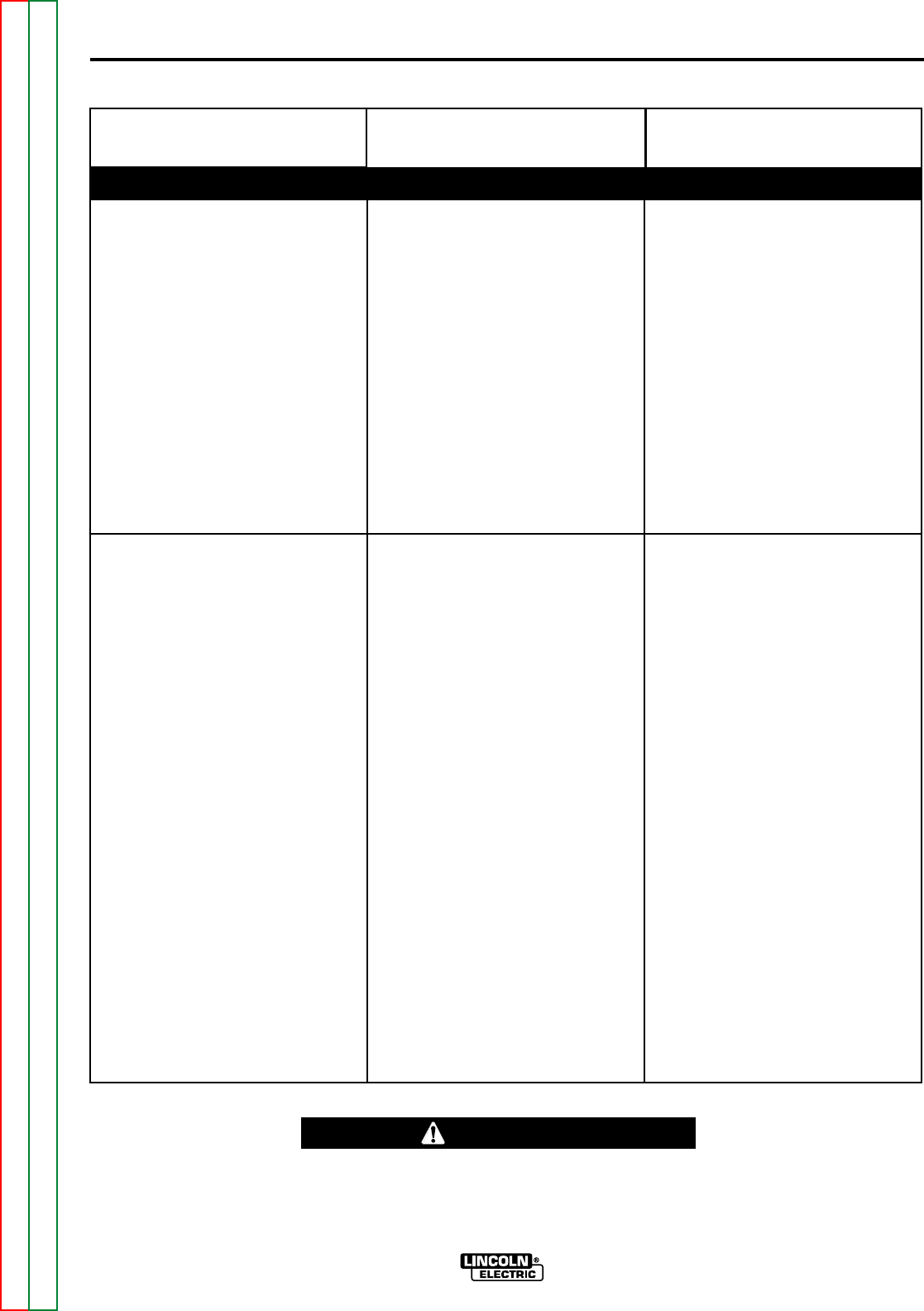

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

The welding arc is variable or

“hunting”.

Poor arc striking with sticking or

“blast-offs”. The bead may be nar-

row, ropey and have porosity.

1. The electrode or work cables

may have faulty connections.

2. Make sure the welding proce-

dures are correct for the

process being used.

3. Make sure the DIP switches on

the control board are set

correctly.

4. The gas shielding may not be

sufficient or contaminated.

5. The power source may be

faulty.

1. Make sure the welding proce-

dures are correct for the

process being used.

2. The gas shielding may not be

sufficient or contaminated.

3. Make sure the set screw in the

connector block is in place and

tightened against the liner

bushing.

4. Weld procedures and/or para-

meters incorrect for process

being performed.

5. The power source may be

faulty.

1. If the drive rolls are turning

erratically perform the Wire

Drive Motor Test and Tach

Adjustment and Feedback

Test.

1. If the drive rolls are turning

erratically perform the Wire

Drive Motor Test and Tach

Adjustment and Feedback

Test.

2. Make certain weld procedures

and parameters are correct for

the process being performed.

WELDING PROBLEMS

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric

Service Department for technical troubleshooting assistance before you proceed. Call 1-800-833-9353.

-----------------------------------------------------------------------------------------------------------------------------

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC