E-5

THEORY OF OPERATION

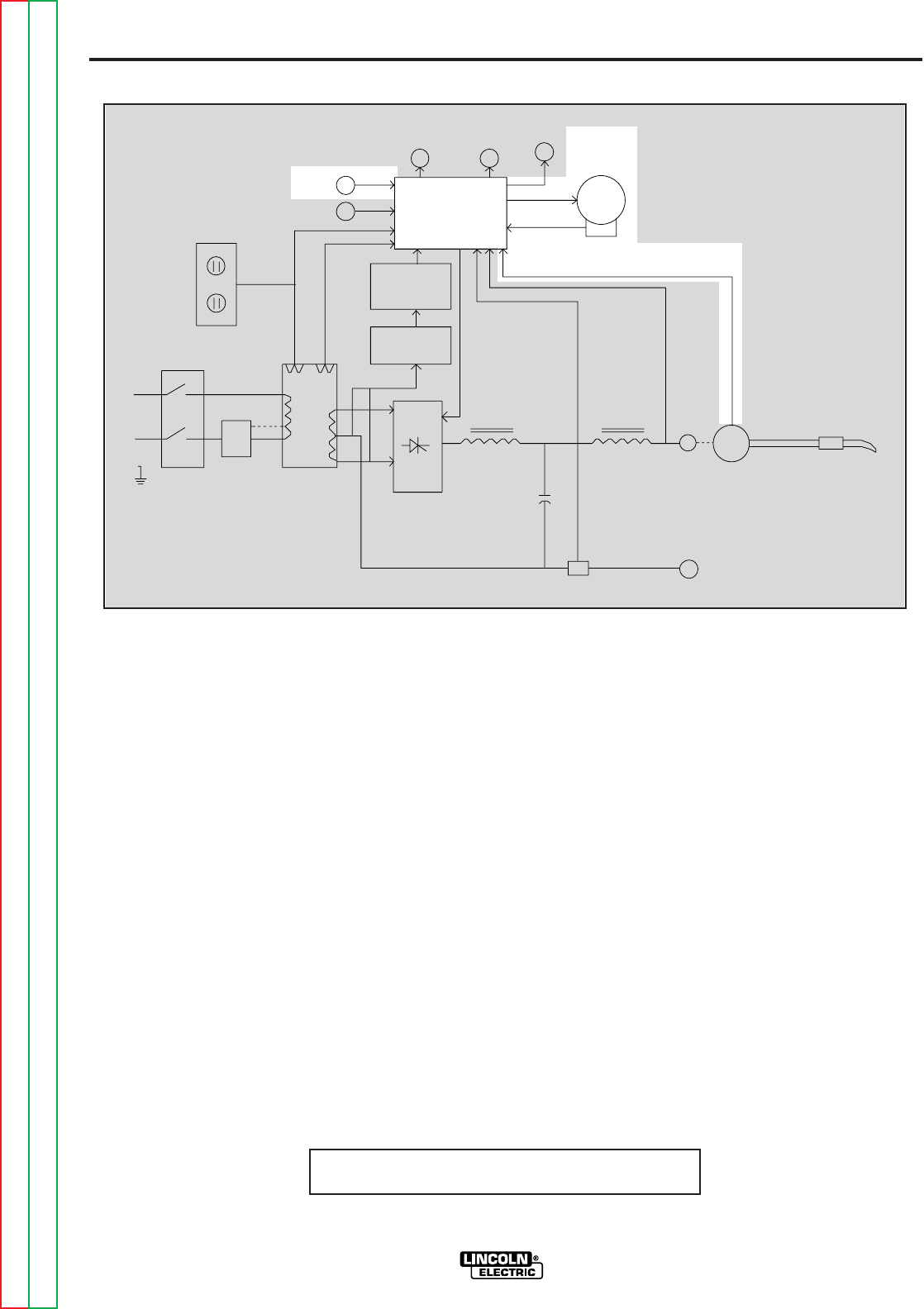

POWER MIG 255C

E-5

WIRE DRIVE MOTOR

AND FEEDBACK

The wire drive motor is controlled by the control board.

A motor speed feedback signal is generated at the

motor tach and sent to the control board. The control

board compares this feedback signal with the com-

mands set forth by the Wire Speed Control poten-

tiometer and sends the appropriate armature voltage to

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

FIGURE E.5 — WIRE DRIVE MOTOR AND FEEDBACK.

LINE

SWITCH

RECONNECT

MAIN

TRANSFORMER

SNUBBER

BOARD

RECTIFIER

DIODE

BRIDGE

ARC

VOLTAGE

WIRE

SPEED

GAS

SOLENOID

FAN

MOTOR

CONTROL

BOARD

WIRE

DRIVE

MOTOR

TACH

GUN TRIGGER

FEEDBACK

115 VAC

30 VAC

G

A

T

E

S

I

G

N

A

L

SCR

RECTIFIER

POWER

ENHANCEMENT

CHOKE

OUTPUT

CHOKE

C

A

P

A

C

I

T

O

R

S

F

E

E

D

B

A

C

K

NEGATIVE

TERMINAL

POSITIVE

TERMINAL

SHUNT

SPOOL

GUN

AUX

the wire drive motor. The drive motor speed is thus

controlled which in turn regulates the electrode wire

feed speed through the gun.

The control board also provides a 3-24 VDC operating

voltage for the optional spool gun. To achieve full WFS

control at the spool gun, the WFS knob on front of the

PM-255C must be set at max.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC