MAINTENANCE

D-2D-2

LN-23P

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

GUN AND CABLE MAINTENANCE

Remove spatter from tip after each ten minutes of arc

time or as required.

Replace worn contact tips and thread protectors as

required.

Replace worn spring liners in nozzles. The life of the

spring can be doubled by rotating it 180°.

Clean cables after using approximately 300 pounds of

electrode. Remove the cable from the wire feeder and

lay it out straight on the floor. Remove the contact noz-

zle tip from the gun. Using an air hose and only partial

pressure, gently blow out the cable from the gun end.

(Too much pressure at the start will cause the dirt to

form a plug.) Flex the cable over its entire length and

again blow out the cable. Repeat this procedure until

no further dirt comes out.

Before any gun is disassembled, remove unit from the

wire feeder or shut off the power source.

WIRE DRIVE ASSEMBLY MAINTENANCE

Every 500 pounds of electrode, the drive roll section

should be inspected and cleaned out if necessary. Do

not use a solvent for cleaning the idle roll as it may

wash lubricant out of the bearing.

Replace drive rolls as required. Drive rolls should be

worn on both sides before replacing. See “A” of this

section.

Check the motor brushes every six months. Replace if

they are less than 1/4" long.

Every year examine the gear box and paint the gear

teeth with moly-disulfide filled grease.

SAFETY PRECAUTIONS

Have qualified personnel do the maintenance

work. Turn the engine off before working inside

the machine. In some cases, it may be

necessary to remove safety guards to perform

required maintenance. Remove guards only

when necessary and replace them when the

maintenance requiring their removal is

complete. Always use the greatest care when

working near moving parts.

-----------------------------------------------------------------------

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

------------------------------------------------------------------------

See additional warning information

throughout this operatorʼs manual and

the Engine manual as well.

-----------------------------------------------------------

WARNING

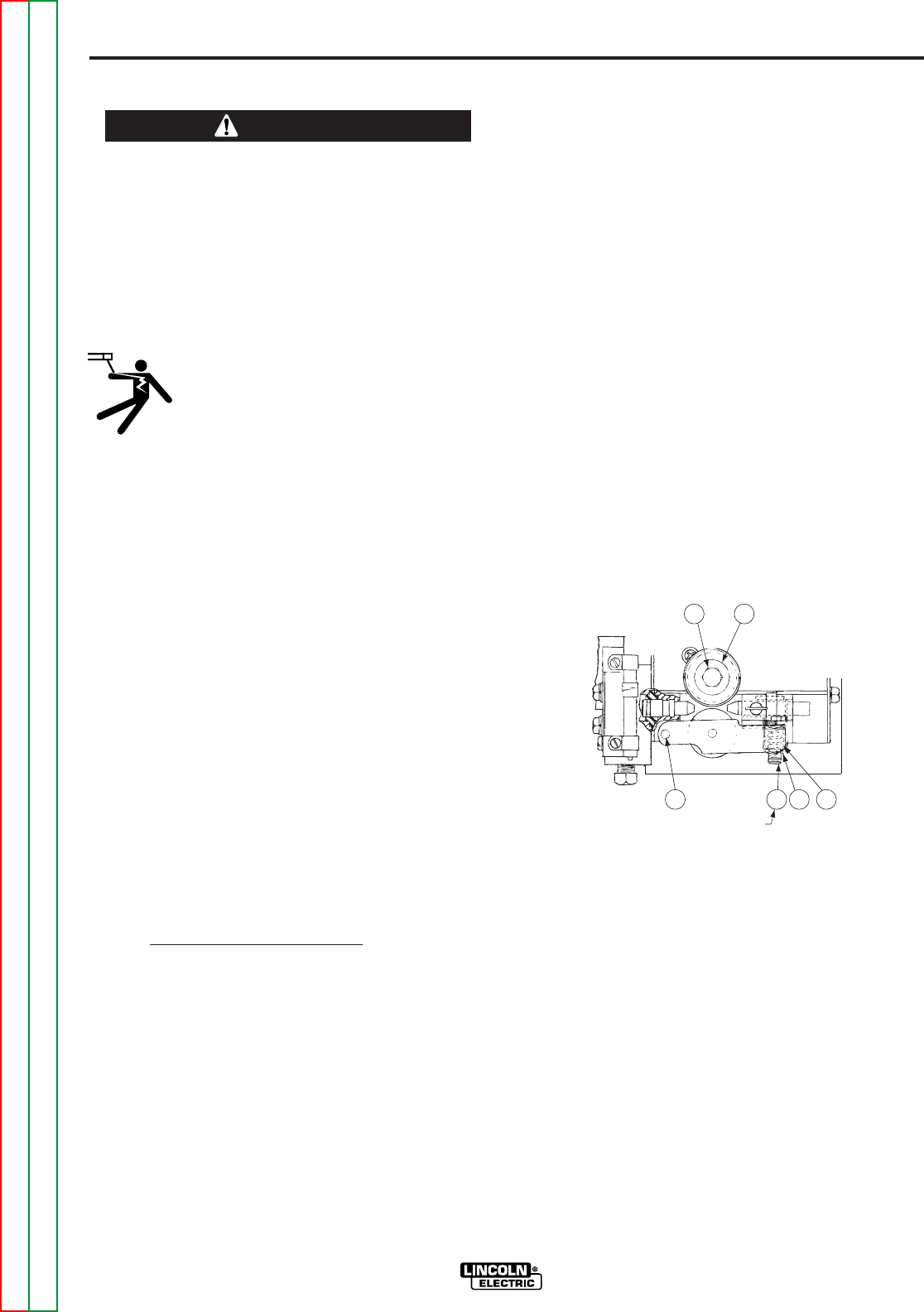

REPLACING OR REVERSING DRIVE ROLLS (See

Figure D.1)

Loosen idle roll tension screw (Item 1) to release pres-

sure between idle roll and drive rolls.

Remove hex head screw (Item 2) with a 1/2" wrench

and remove the drive roll clamping collar (Item 3).

Remove drive rolls from shaft.

Wipe the drive roll surfaces clean. Then install new

drive rolls. If reversing drive rolls, turn drive rolls over so

unworn teeth face each other.

Replace clamping collar and hex head screw.

Tighten the idle roll tension screw until it bottoms and

then back it out two complete turns. If feeding problems

persist, do not increase the tension. check for other

issues such as the wire spool binding or a dirty or dam-

aged gun cable

REMOVING IDLE ROLL ASSEMBLY

Remove the idle roll tension screw (Item 1), tension

spring retainer (Item 4), and tension spring (Item 5).

Pivot the idle roll assembly away from the gearbox and

lift it off the pivot pin (Item 6).

To re-assemble, replace idle roll assembly, tension

spring, retainer, and tension screw. Adjust the tension

screw as described above.

23

614

5

IDLE ROLL TENSION

ADJUSTING SCREW

FIGUIRE D.1