LN-23P

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-14 F-14

TROUBLESHOOTING AND REPAIR

POTENTIOMETER TEST (cont.)

TEST PROCEDURE

WIRE SPEED CONTROL POTENTIOMETER

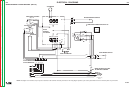

1. Disconnect leads 641, 642 and 535 from the Control

Board. (See Figure F.4)

a. Check resistance between lead 535 and

lead 641 for a reading of 10kΩ +/-10%.

A low reading or an ʻopenʼ reading indicates a

defective potentiometer.

b. Connect the ohmmeter to leads 641 and

642, and rotate the control slowly from min

to max speed setting.

The meter should vary smoothly from 10kΩ

to 0 Ω.

c. Repeat test ʻbʼ with meter connected to

leads 642 and 535.

Any irregularity or ʻskippingʼ in the meter read-

ing indicates a defective potentiometer.

d. Check all three leads to the potentiometer

case. Reading must be >500kΩ.

VOLTAGE CONTROL POTENTIOMETER

For codes above 10892 (8 pin connector)

1. Disconnect the Control Cable from the back of the

feeder.

NOTE: See Figure F.4 for Pin locations

a. Check resistance from Pin F(75) to Pin H

(77) of the box connector for a reading of

10kΩ +/- 10%.

A low reading or an ʻopenʼ reading indicates a

defective.

b. Connect the meter from Pin F(75) to Pin

G(76) and rotate the control slowly from min

to max voltage setting.

The meter should vary smoothly from 0 Ω to

10kΩs.

c. Repeat test ʻbʼ with meter connected to Pins

G and H.

Any irregularity or ʻskippingʼ in the meter read-

ing indicates a defective potentiometer.

d. Check all three leads to the potentiometer

case. Reading must be >500kΩ.

NOTE: Codes below 10892 have a 6 pin connector.

Test points will be pins E(75), D(76) and

F(77)

FIGURE F.4

LN-23P

Control

Board

535

641

642

F

A

B

C

D

E

G

A

B

C

D

E

F

H

Codes Below 10892

Codes 10892 & Above

76

75

77

77

75

76