Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

LN-23P

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

Since the K350 (-1) adapter is the communication link between the feeder and the power source,symptoms that

seem to indicate a defective feeder may be due to a defective adapter or control cable. If a working feeder and

cable is available, connecting it will help to isolate the problem. If this is not convenient, either replace the

adapter or follow the troubleshooting steps for the K350.

F-6 F-6

TROUBLESHOOTING AND REPAIR

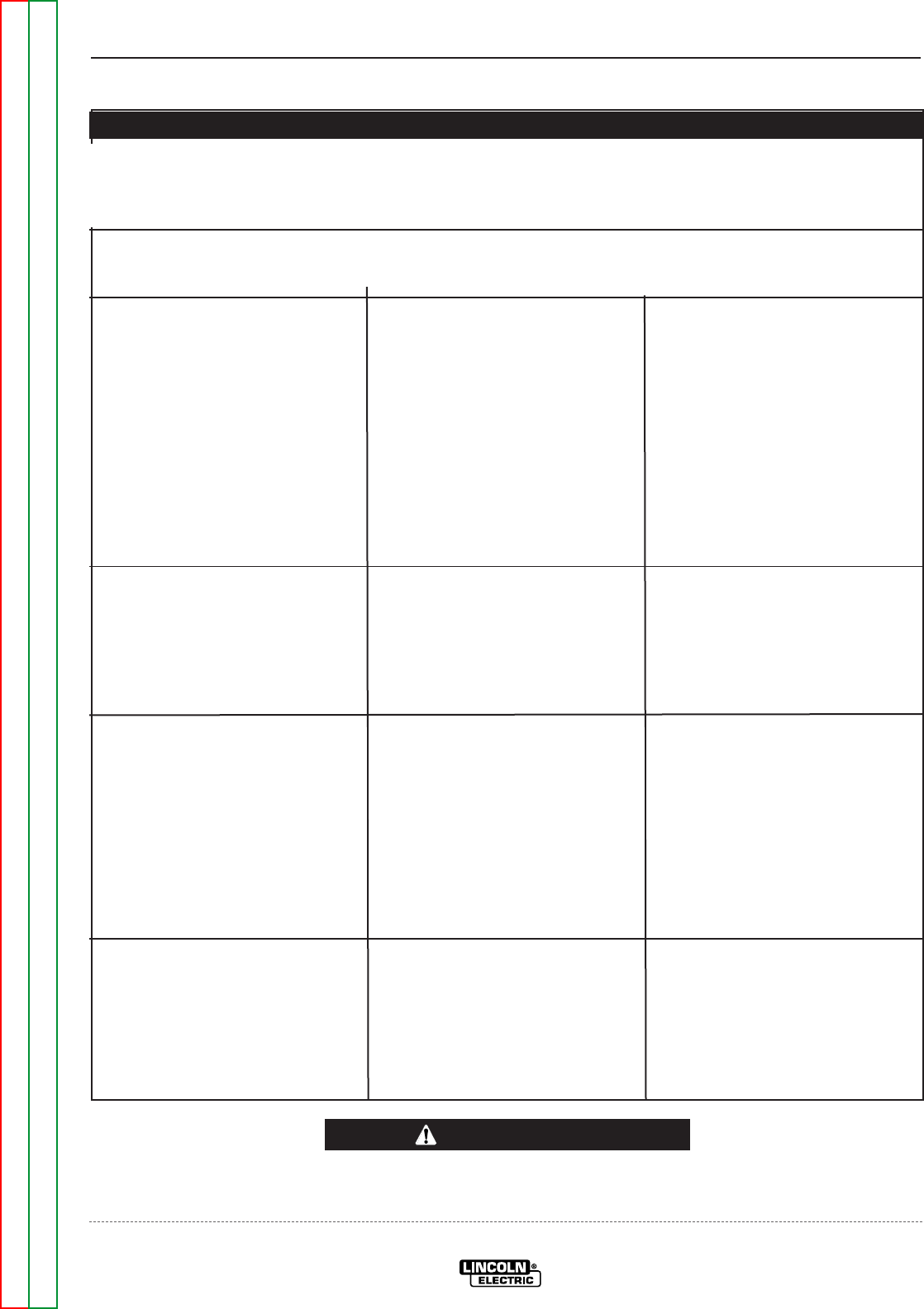

K350 ADAPTER PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

Motor wonʼt run. No voltage on the

meter. Feeder checks OK and

power source has output.

NOTE: Symptoms on this page

assume that the LN-23P is

connected to Feeder “A”

terminal strip

1. Disconnect the Work Sensing

lead from the terminal strip and

with power applied to the K350,

check for continuity from the #21

terminal to #521 on Feeder ”A”

Terminal strip.

2. Check for 24VAC at terminals

605 &606 at PC Board.

1. If reading is 0 ohms, check the

control cable to the LN-23P.

2. If the voltage is 0, check for

120vac at terminals #31 & #32.

3. Make sure the power source is

supplying 120vac to the cable.

4. Perform the K350 Adapter test.

Motor wonʼt run when trigger is

pulled. OCV shows on voltmeter.

1. Temporarily jumper #602 from

terminal strip to #610.

1. If motor runs, check connections

to relay. Replace 2CR relay.

If motor does not run check

leads 602 & 604 from terminal

strip to PC Board and to 2CR.

No voltage control or cannot obtain

desired voltage.

1. Run test with the power source

in ʻLOCALʼ control.

2. Check the Voltage Control

potentiometer.

1. If desired voltage can be

achieved;

• Check cable from power

source to adapter.

• Check connections from

Feeder “A” terminal strip to

1CR.

2. Perform the Potentiometer

test.

Feeder A works OK, Feeder B does

not

1. Make sure 2CR relay operates

when Feeder “B” trigger is

pulled.

1. If relay does not operate:

• Check wiring from Feeder”B”

terminal strip.

• Perform the K350 Adapter

test.