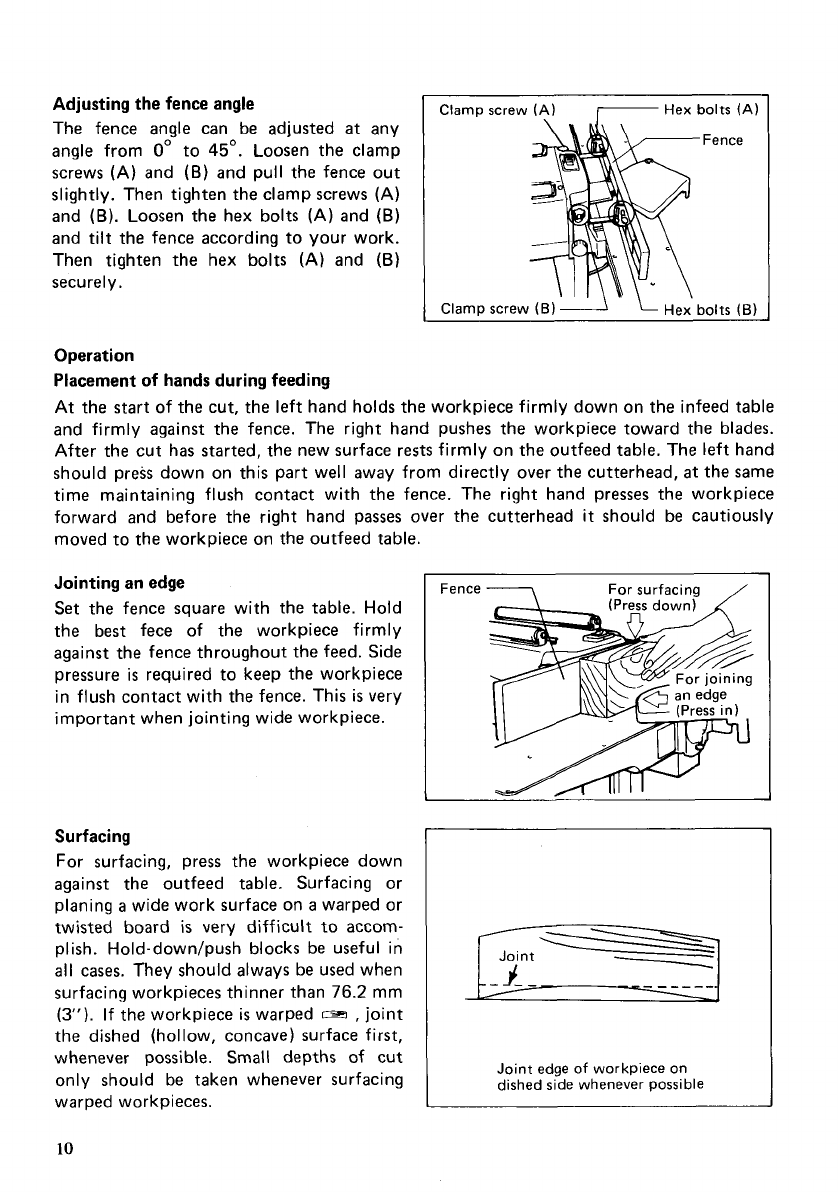

Adjusting the fence angle

I

ClamD

screw

(A)

7

Hex bolts

(A)

The fence angle can be adjusted

at

any

angle from

0’

to 45’. Loosen the clamp

screws

(A)

and

(B)

and pull the fence out

slightly. Then tighten the clamp screws (A)

and

(B).

Loosen the hex bolts

(A)

and

(B)

and

tilt

the fence according to your work.

Then tighten the hex bolts

(A)

and

(B)

securely.

-Fence

bolts

(6)

Operation

Placement of hands during feeding

At the start

of

the cut, the left hand holds the workpiece firmly down on the infeed table

and firmly against the fence. The right hand pushes the workpiece toward the blades.

After the cut has started, the new surface rests firmly on the outfeed table. The left hand

should press down on this part well away from directly over the cutterhead,

at

the same

time maintaining flush contact with the fence. The right hand presses the workpiece

forward and before the right hand passes over the cutterhead

it

should be cautiously

moved to the workpiece on the outfeed table.

Jointing an edge

Set the fence square with the table. Hold

the best fece of the workpiece firmly

against the fence throughout the feed. Side

pressure

is

required to keep the workpiece

in flush contact with the fence. This

is

very

important when jointing wide workpiece.

Surfacing

For surfacing, press the workpiece down

against the outfeed table. Surfacing or

planing

a

wide work surface on

a

warped or

twisted board

is

very difficult to accom-

plish. Hold-down/push blocks be useful in

all

cases.

They should always be used when

surfacing workpieces thinner than

76.2

mm

(3”).

If the workpiece

is

warped

m

,

joint

the dished (hollow, concave) surface first,

whenever possible. Small depths of cut

only should be taken whenever surfacing

warped workpieces.

Fence

L-1

Joint

I

Joint edge of workpiece on

dished side whenever possible

10