OM-4405 Page 28

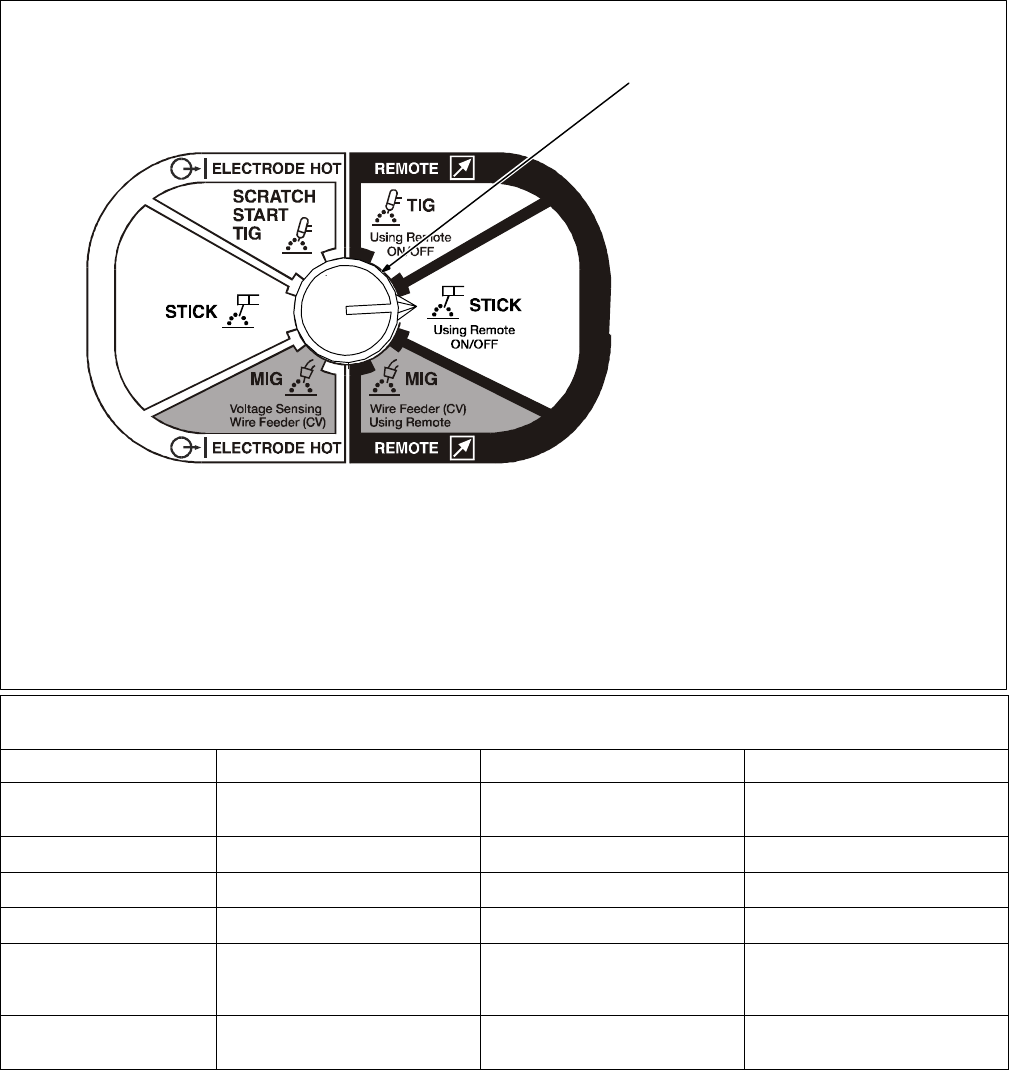

6-3. Process/Contactor Switch On CC/CV Models

1

1 Process/Contactor Switch

Y Weld output terminals are en-

ergized when Process/Con-

tactor switch is in an Electrode

Hot position and the engine is

running.

Use switch to select weld process

and weld output on/off control (see

table below and Section 6-4).

Place switch in Remote positions to

turn weld output on and off with a de-

vice connected to the remote 14 re-

ceptacle.

Place switch in Electrode Hot posi-

tions for weld output to be on whenev-

er the engine is running.

Use Stick position for air carbon arc

(CAC-A) cutting and gouging.

When switch is in a Stick position, the

arc drive (dig) circuit provides addi-

tional amperage during low voltage

(short arc length conditions) to pre-

vent “sticking” electrodes.

The arc drive (dig) circuit is disabled

when switch is in MIG or TIG

positions.

. Place switch in Electrode Hot -

Stick position when using option-

al auxiliary power plant (see Sec-

tion 7-2).

. The engine auto idle function

does not work in the Remote-TIG

mode.

Process/Contactor Switch Settings

Switch Setting Process Output On/Off Control Engine Auto Idle

Remote – TIG

GTAW With HF Unit, Pulsing

Device, Or Remote Control

At Remote 14 Receptacle Not Active

Remote – Stick Stick (SMAW) With Remote On/Off At Remote 14 Receptacle Active

Remote – MIG MIG (GMAW) At Remote 14 Receptacle Active

Electrode Hot – MIG MIG (GMAW) Electrode Hot Active

Electrode Hot – Stick

Stick (SMAW),

Air Carbon Arc (CAC-A) Cutting

And Gouging

Electrode Hot Active

Electrode Hot – Scratch

Start TIG

Scratch Start TIG (GTAW) Electrode Hot Active