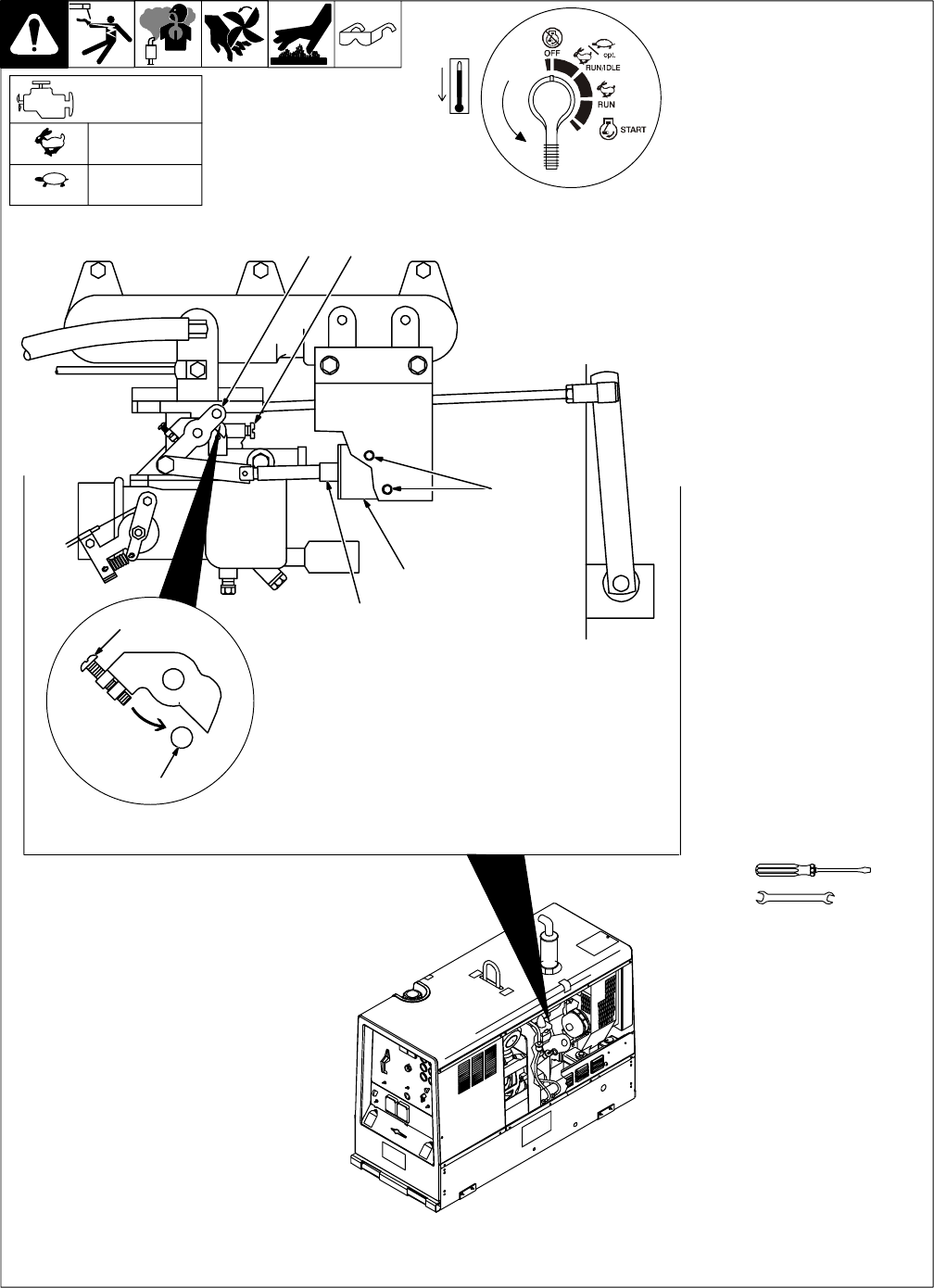

OM-4405 Page 38

8-6. Adjusting Engine Idle Speed

802 731 / Ref. 115 155-A

Y Stop engine and let cool.

Engine idle speed is factory set and

normally should not require adjust-

ment. After tuning engine, check

engine speed with tachometer or

frequency meter. See table for

proper no load speed. If necessary,

adjust idle speed as follows:

Start engine and run until warm.

On CC Models, place Stick/TIG

switch in Stick position.

On CC/CV models, turn Process/

Contactor switch to Stick – Elec-

trode Hot position.

1 Solenoid Bracket Screws

2 Throttle Arm

3 Idle Speed Screw

4 Throttle Stop

Loosen bracket screws and move

arm so screw touches stop. Do not

release arm. Turn idle speed screw

to obtain 550 rpm.

5 Idle Mixture Screw

Turn mixture screw counterclock-

wise until engine falters, then turn

screw clockwise until engine runs

smoothly.

Turn idle speed screw to obtain

1250 rpm.

6 Solenoid

7 Plunger

Slide solenoid inside bracket so

plunger bottoms in solenoid. If nec-

essary, shim solenoid/bracket to

prevent linkage from binding. Do

not readjust idle speed screw when

adjusting solenoid.

Tighten bracket screws. Release

throttle arm. Recheck idle speed

and readjust if necessary.

Y Stop engine.

Close door.

Tools Needed:

1

2

3

4

5

6

7

1/4 in

1850 rpm max

(61.6 Hz)

1250 rpm

(41.6 Hz)

Engine Speed

(No Load)