OM-4405 Page 35

500 h

Repair Or

Replace

Damaged

Cables.

Check

Valve

Clearance.*

1000 h

Blow Out Or

Vacuum Inside.

During Heavy

Service,

Clean Monthly.

OR

Drain Sludge

From Fuel

Tank. See

Section 8-8.

FUEL

SLUDGE

Service Welding Generator

Brushes And Slip Rings. Service

More Often In Dirty Conditions.*

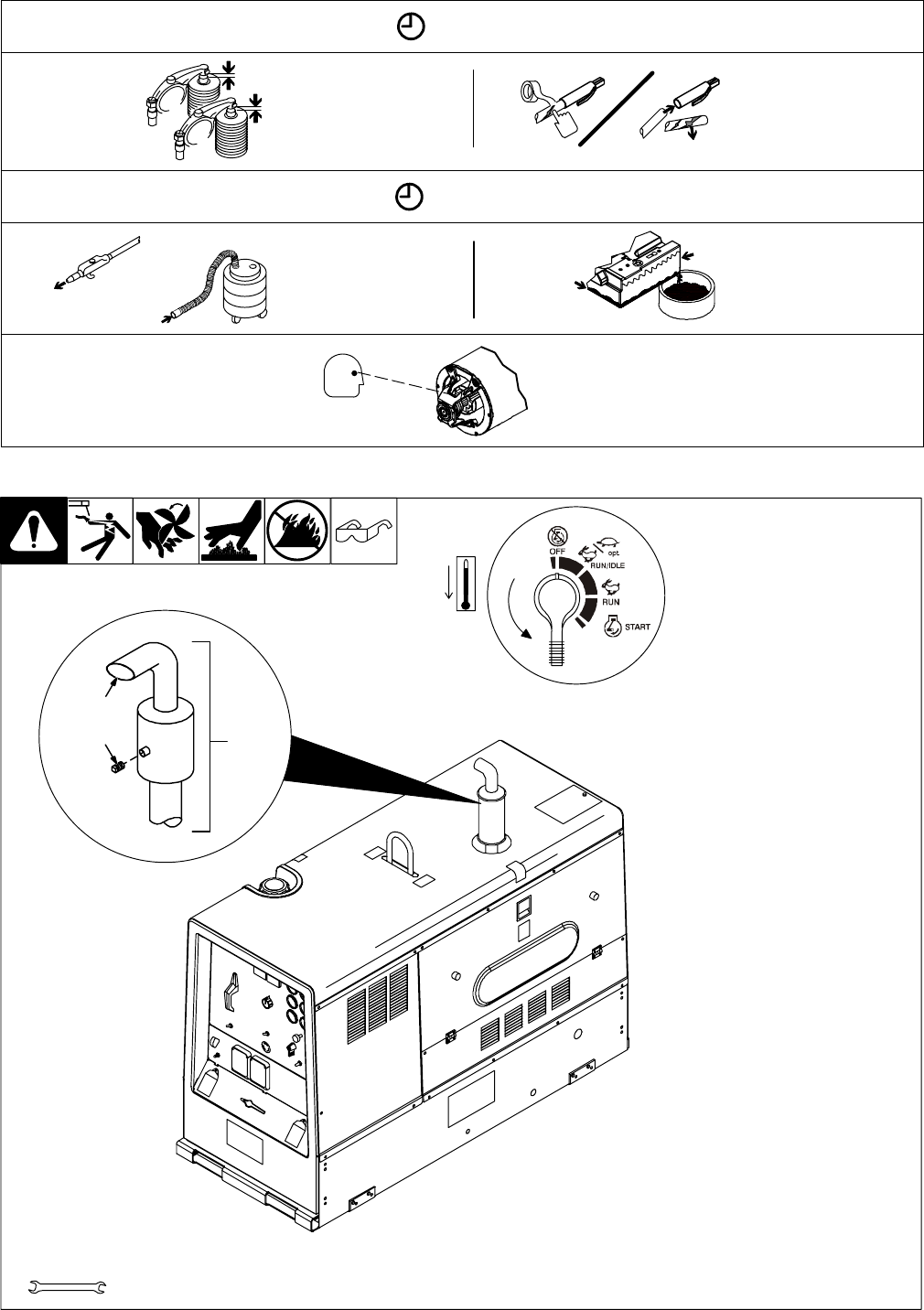

8-3. Inspecting And Cleaning Optional Spark Arrestor Muffler

802 729 / Ref. 201 841

Y Stop engine and let cool.

1 Spark Arrestor Muffler

2 Cleanout Plug

Remove plug and remove any dirt

covering cleanout hole.

3 Exhaust Pipe

Start engine and run at idle speed to

blow out cleanout hole. If nothing

blows out of hole, briefly cover end

of exhaust pipe with fireproof

material.

Y Stop engine and let cool.

Reinstall cleanout plug.

Tools Needed:

3

2

1

3/8 in