TM-499 Page 22

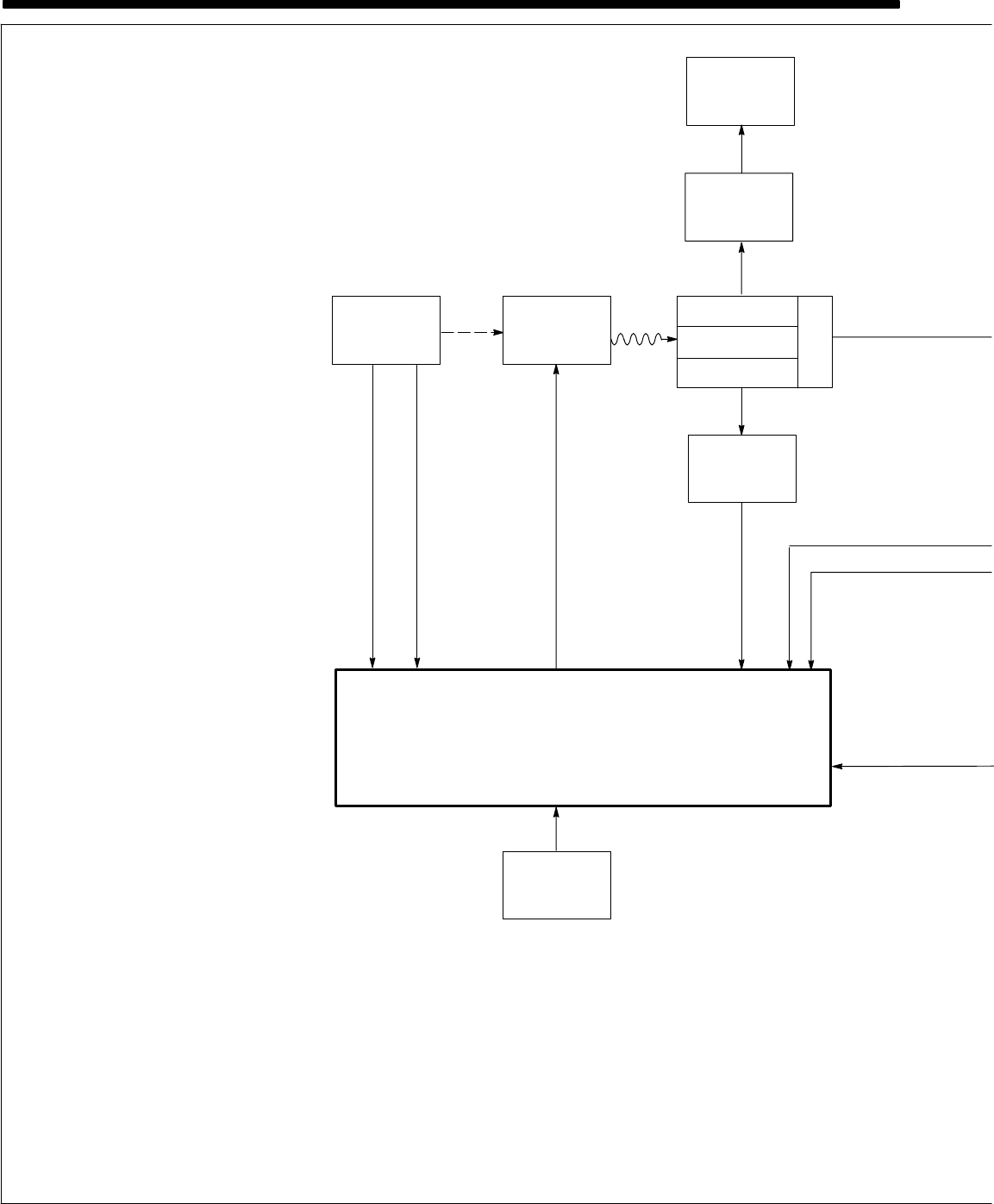

1 Engine

Supplies force to turn revolving

fields.

2 Revolving Field (Rotor)

Turns at 3700 rpm maximum (60

Hz) for weld and power. The speed

and excitation current of the field

coils determine voltages in stator

windings.

3 Stator Windings

Supply power to exciter, generator

power, and weld circuits.

4 Integrated Rectifier SR1

Changes ac output of stator

windings to dc to supply excitation

current to the exciter revolving field.

5 Control Board PC1

Adjusts weld output by changing

revolving field current after

comparing feedback to amperage

setting of R1.

Uses current feedback signal for

foldback circuit to prevent stator

failure from short-circuit conditions.

Use voltage feedback signal to

maintain open-circuit and genera-

tor power voltages regardless of

Current Control R1 setting.

Monitors engine speed and stops

weld and power output when speed

drops below 2700 rpm.

6 Current Control R1

Changes output of stator weld

windings by adjusting field current

level in revolving field.

7 Generator Power Circuit

Breakers

Protect ac receptacles from over-

load.

8 Generator Power AC

Receptacles

Provide connection points and

power for auxiliary equipment.

SECTION 8 − THEORY OF OPERATION

Integrated

Rectifier

SR1

Revolving

Field

(Rotor)

Engine

Exciter

Stator Windings

Weld

6

4

213

Control

Board

PC1

Circuit

Breakers

Generator

7

8

Generator Power

5

Power AC

Receptacles

Current

Control R1

AC Supply

Engine Speed Feedback Signal

Excitation DC Supply

Generator Power