TM-499 Page 45

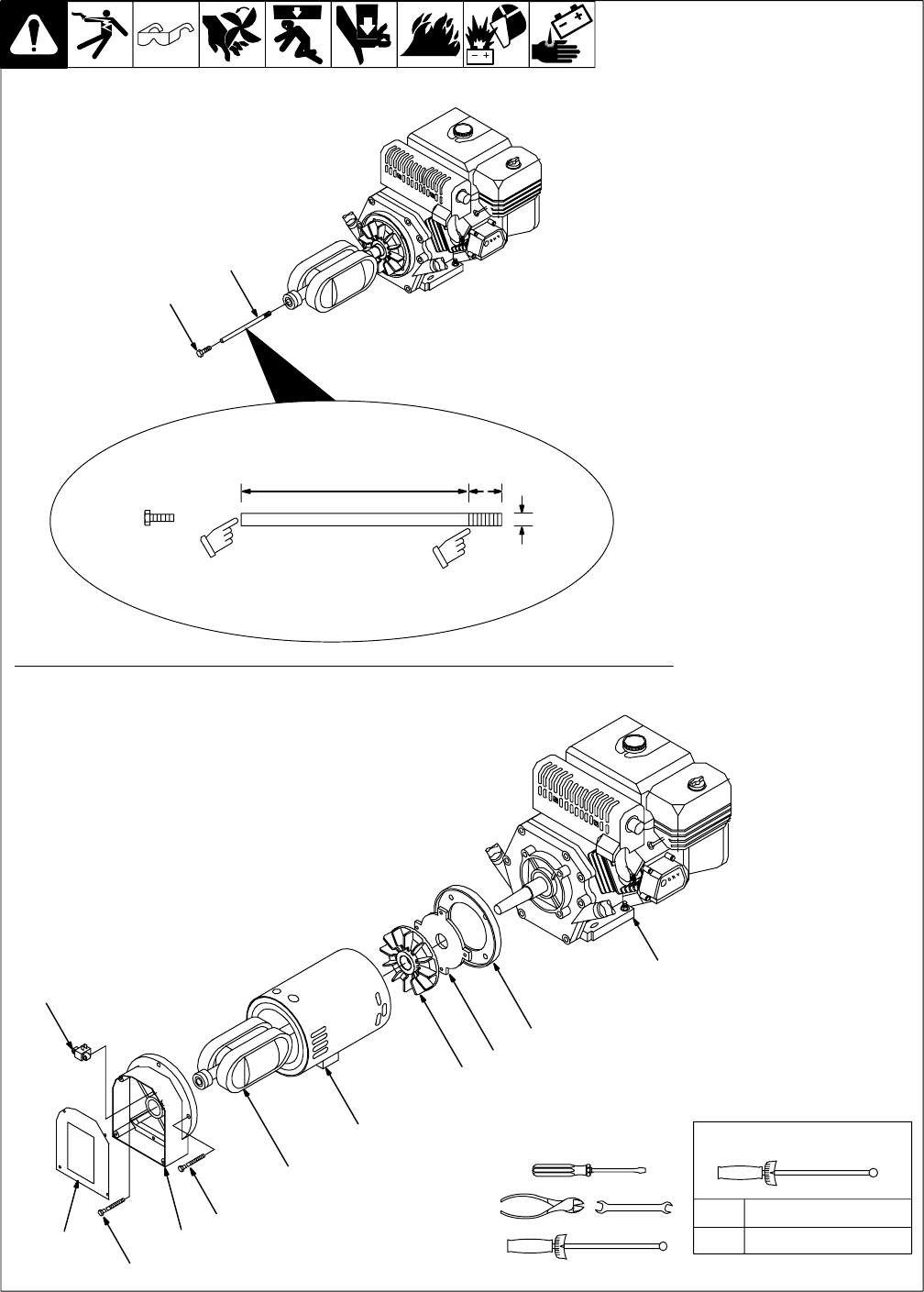

11-2. Removing Rotor And Reassembling Generator

802 524 / 802 509

Y Do not damage rotor or sta-

tor windings during this pro-

cedure.

To remove rotor:

1 Rotor Removal Tool

(Customer Supplied)

2 Screw, 7/16-14 x 1-1/4

(Customer Supplied)

Remove rotor thru-bolt.

Make rotor removal tool from

stress-proof steel rod according to

specifications. Slide threaded end

of tool through rotor. Tighten tool in

engine shaft. Turn screw into rotor

while lightly tapping rotor lamina-

tions. (turning screw into rotor

forces rotor off engine shaft.)

Reassembly

3 Brushholder Assembly

4 Generator End Panel

5 Bearing Carrier

6 Rotor Assembly

7 Stator Assembly

8 Generator Fan

9 Generator Guard

10 Engine Adapter

11 Engine

Reinstall engine and generator

parts using torque values in table.

Reconnect all leads. Use cable ties

to secure leads in wiring harness

and away from moving or hot parts.

Reinstall cover.

A 95 in lb (10.7 N

.

m)

B 205 in lb (23.1 N

.

m)

Torques:

Tools Needed:

3

4

5

6

7

8

9

10

11

A

B

1 in

(25.4 mm)

5/16 in

(8 mm)

7-1/2 in

(191 mm)

1

2

Cut screwdriver

slot in end of rod.

Removing Rotor

Reassembling Generator

24 threads

per inch