TM-499 Page 25

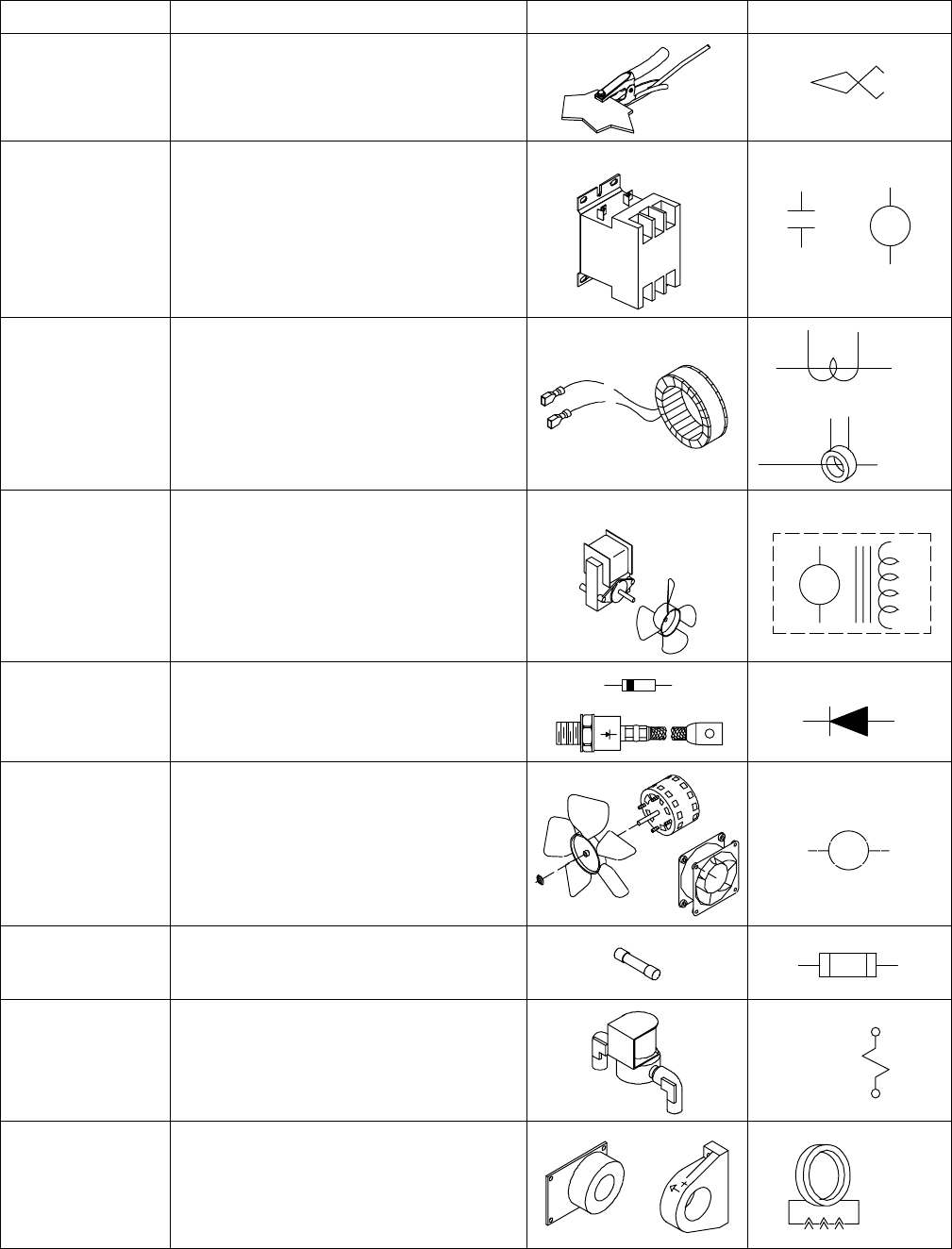

PART NAME CIRCUIT SYMBOLPICTUREFUNCTION

CLAMP A spring-loaded connection device. A good

example would be the “work clamp” used to

connect the weld cable from a power source

to the workpiece that will be welded.

CONTACTOR A heavy duty relay. Usually used to make

and break the welding arc or primary power.

W

COIL

NRM OPEN

POINTS

W

CURRENT

TRANSFORMER

A transformer that produces an AC voltage

used for measuring purposes. The primary

winding is in series with the circuit carrying

the current to be measured. Its main use in

engine-driven equipment is to activate the

“Automatic Idle” circuit by sensing welding

current or auxiliary power current.

CT1

OR

CT1

DASHED LINE A dashed line between parts means there is

a mechanical connection between these

parts. When a dashed line boxes in parts,

this means the parts make up an option or

are combined into one part. In all cases,

dashed lines do not conduct electricity. The

picture shown is a combination fan motor and

transformer in one part.

FM

DIODE A device that allows current to flow in one

direction only. Most common use is to

change AC to DC.

D1

FAN MOTOR This device provides cooling of the internal

parts of a welding power source.

FM

FUSE A protection device, usually an enclosed

piece of wire that melts and breaks the circuit

when the current exceeds the fuse rating.

F1

GAS OR WATER

SOLENOID

(VALVE)

These are electromechanical devices used to

start or stop the flow of shielding gas or

water.

GS1

OR

WS1

HALL DEVICE Produces a small DC voltage proportional to

the current it is sensing (usually welding

current). This feedback signal can be used to

regulate the welding output (line voltage

compensation). It may even be used to drive

an ammeter.

HD1