TM-499 Page 43

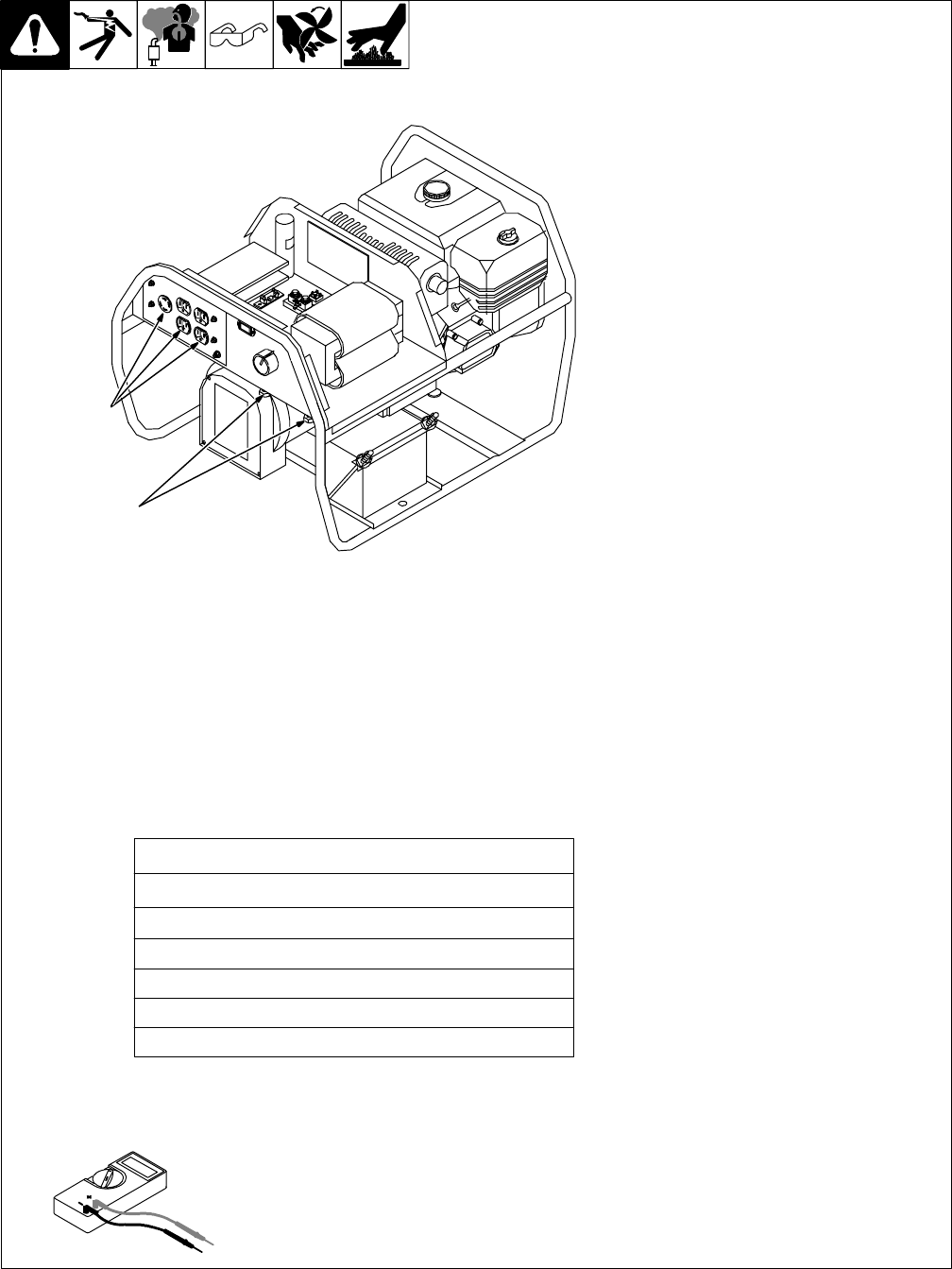

10-8. Checking Unit Output After Servicing

ST-802 524

Start engine.

Move throttle control lever to 60 Hz

position.

1 Weld Output Terminals

Check open-circuit voltage across

weld output terminals. There

should be 68 volts dc present (see

Section 10-2).

2 AC Receptacles RC1, RC2,

And RC3

Move throttle lever to correct

position (50 or 60 Hz) for generator

power. Check voltage at each

receptacle. With no load applied,

voltage should be 10% above

receptacle rating on nameplate.

EXAMPLE: Correct no load voltage

for a 120 volt receptacle should be

132 volts ac.

If generator power or weld output

voltage is incorrect, adjust engine

speed (see Section 7-4 or 7-5).

Y Stop engine. Close fuel

valve.

Allow engine to cool, and complete

pre-operational checks in table.

1

Test Equipment Needed:

Pre-Operational Checks

Wipe engine surfaces clean.

Check labels; replace labels that are unreadable or damaged.

Check and correct any fluid leaks.

Clean weld output and battery terminals. Tighten connections.

Clean outside of entire unit.

Check fuel and oil (see Section 4-4 or 4-5).

2