7

Glossary of Terms for Woodworking

Bed

The combination of infeed and outfeed table surfaces

which support the workpiece during a cutting operation.

Bevel/Chamfer

Removing wood along the edge of a board to make that

edge straight, smooth and angled to the board face which

is against the fence.

Cutter Guard

Spring loaded guard or shield covering the cutter head.

Cutter Head

The cutter head is a rotating piece with three adjustable

knives. The cutter head removes material from the work-

piece

Depth of cut

A term used to indicate how deep into the workpiece the

cutter knives will cut.

Fence

The fence is attached to the jointer/planer base. The

fence helps support and guide the workpiece as it is

pushed across the cutter head.

Freehand

Using the tool without holding the workpiece firmly

against the fence and

table. This can let the workpiece

twist and kick back and must never be attempted.

Gum

A sticky, sap based residue from wood products.

Hold-Down/Push-Blocks

They are required for your own safety. They are used to

hold your workpieces against the table and

fence when

planing, rabbeting or jointing.

Infeed Table

The section of the jointer bed upon which the workpiece

is placed before being pushed into the cutter head.

Infeed table height is adjustable which allows the opera-

tor to select the depth of cut.

Jointing

The removal of wood along the edge of a board so as to

make that edge straight, smooth and square to the board

face which is against the fence.

Kickback

An uncontrolled grabbing and throwing of the workpiece

back toward the operator by the rotating cutter head.

Leading End

The end of the workpiece which is pushed into the cutter

head first.

Outfeed Table

The section of a jointer bed which supports the workpiece

after it passes over the cutter head.

Planing

Removing wood from the widest surface or face of a

board so as to make it flat and smooth.

Rabbet

A notch cut into the edge of workpiece.

Resin

A sticky, sap based substance that has hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Throw-Back

Throwing of pieces in a manner similar to a kickback.

Trailing End

The workpiece end last cut by the knives.

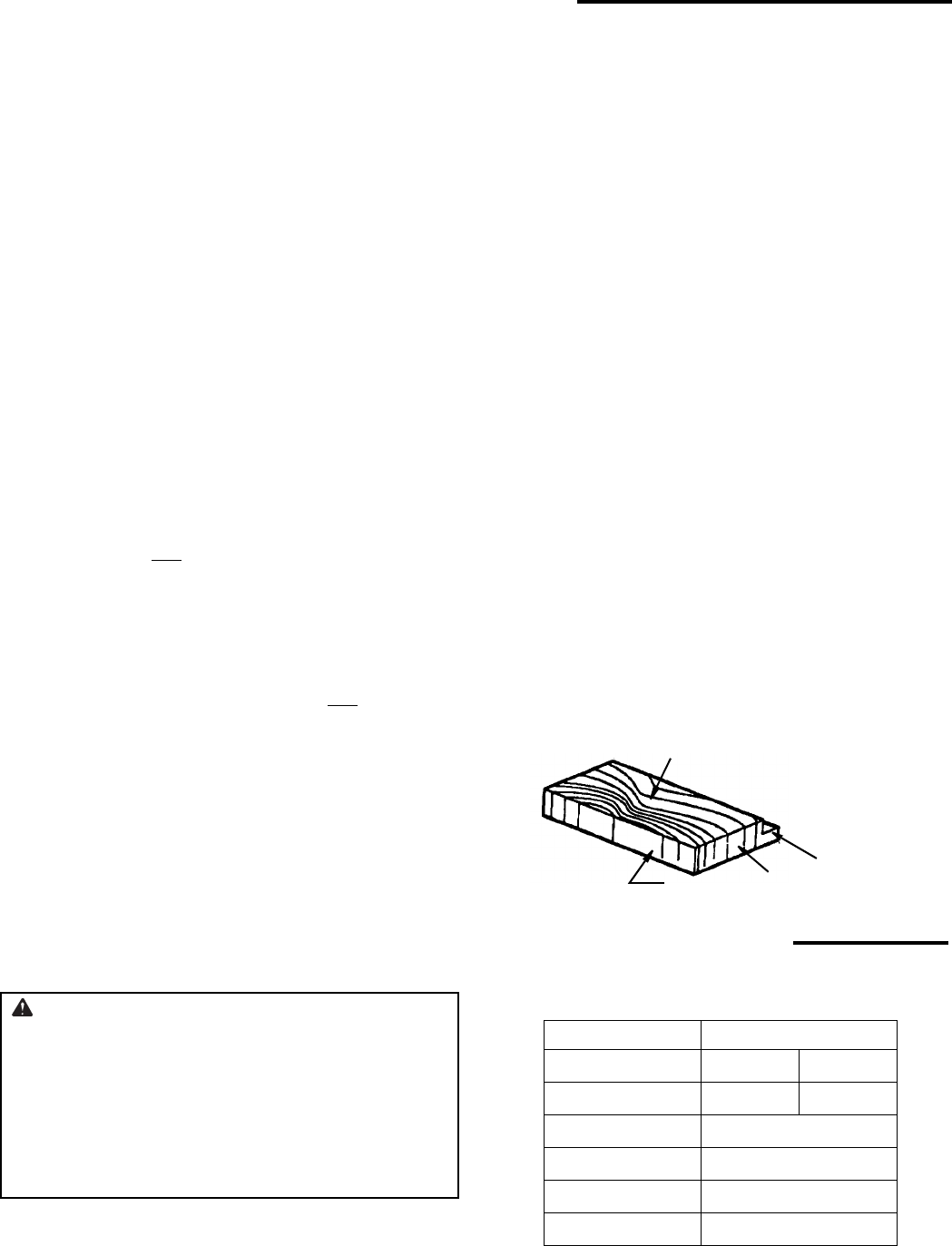

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends and edges.

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of electrical hazards,

fire hazards or damage to the tool, use proper circuit

protection. Your tool is wired at the factory for opera-

tion using the voltage shown. Connect tool to a power

line with the appropriate voltage and a 15-amp branch

circuit. Use a 15-amp time delay type fuse or circuit

breaker. To reduce the risk of shock or fire, if power

cord is worn or cut, or damaged in any way, have it

replaced immediately.

The A/C motor used on this tool is a capacitor start, non-

reversible type, wired at the factory for 110-120V AC, 60 Hz.

operation. Follow the instructions on page 8 to connect the

motor for 220-240V A/C operation.

Face

Edge

End

Rabbet

Rated Horsepower 1

Voltage

110-120 220-240

Amperes

12 6

Hertz (Cycles)

60

Phase

Single

RPM

3450

Rotation of Shaft

Counterclockwise