31

When You Can Cut, and When You

Must Scrape

There are two different approaches to the

work when turning. One approach is

toward a circumference of the workpiece

(for example, turning down the outer sur-

face of a cylinder or the inner wall of a hol-

low round box). In this approach, the

surface being turned travels under the

chisel edge like an endless belt. The sec-

ond approach is toward the diameter of a

workpiece (as when turning the face of a

faceplate turning, or the side of a large

shoulder on a spindle turning). In this

approach the surface being turned rotates

like a disc under the chisel edge. Some-

times the approach will be a combination

of both.

Either a cutting or scraping action can be

used when the approach is toward a cir-

cumference - the shaving is removed like

a peeling from a potato. Scraping, only,

can be used when the approach is toward

a diameter. The reason is obvious when

you consider that faceplate turning practi-

cally always requires removal of wood

across the grain. Wood does not peel

easily across the grain, and attempts to

use cutting methods will likely result in

damage to the work and throwing of the

chisel by the work.

It follows that a cutting action is used for

the general run of spindle turning opera-

tions...while the major part of a faceplate

turning is done by the scraping method.

When a combination approach is to be

used, you will have to judge, by the feel of

the work, when to stop cutting and start

scraping. Never try to cut when it

becomes difficult to hold the chisel

against the roughness of the wood grain.

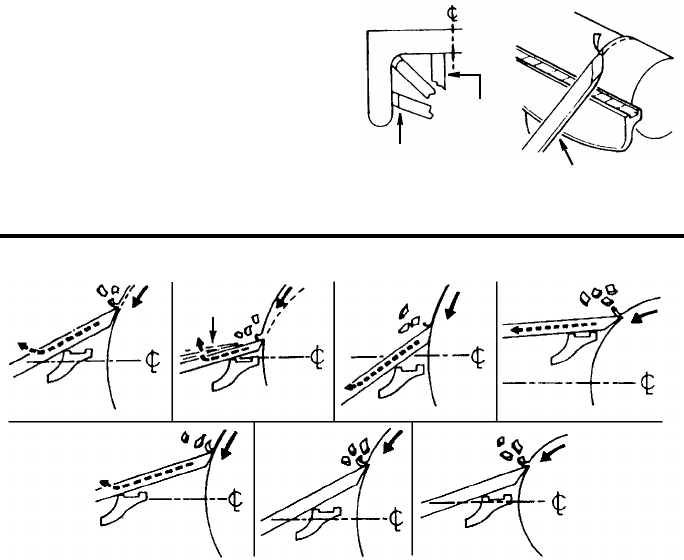

How to Position Tool Rest for Circum-

ference Cutting

When cutting, the object is to pierce the

outer skin of wood to a certain desired

depth, then to hold the chisel steady, with

the bevel edge parallel to the work cir-

cumference, so that it will peel off a shav-

ing at this desired depth. The only sure

method of holding the chisel steady is to

rest the bevel against the work, as shown

in sketch 1. When the tool rest is at the

proper height (sketch 1), the chisel can be

held with the bevel pressed against the

work, and the tool rest will act as a ful-

crum to support the chisel against the

downward force of the revolving work.

Diameter

Approach

Circumference

Approach

Circumference

Approach

Steady

Thrust

Against

Hands

12 3 4

5

6

7

Force

against

work

.

Chisel

cutting

properly

.

Chatter

No support

for

bevel

point

digging

in.

Bevel

Kickback

Kickback

Handle

Kicked Up

Small

Diameter

Rest too low;

chisel too horizontal.

Rest

too low.

Chisel

too high.

Rest too

high

-

chise

l

too high

on work

.

Rest too distant-chisel too

high, point too far from rest.

Large

Diameter