38

How to Use Your RIDGID Wood Lathe (continued)

Cutting Vees

Vee grooves can be cut with either the toe

or heel of the skew. When the toe is used,

the cutting action is exactly the same as in

trimming a shoulder - except that the

skew is tilted to cut at the required bevel.

Light cuts should be taken on first one

side then the other, gradually enlarging

the vee to the required depth and width.

When the heel is used, the skew is

rotated down into the work, using the rest

as a pivot. Otherwise, cutting position and

sequence of cuts is the same. As when

using the toe, it is important that cutting

be done only by extreme end of cutting

edge.

If deep vees are planned, it is quicker to

start them by making a sizing cut at the

center of each vee. Vees can also be

scraped with the spear point chisel or a

three-sided file.

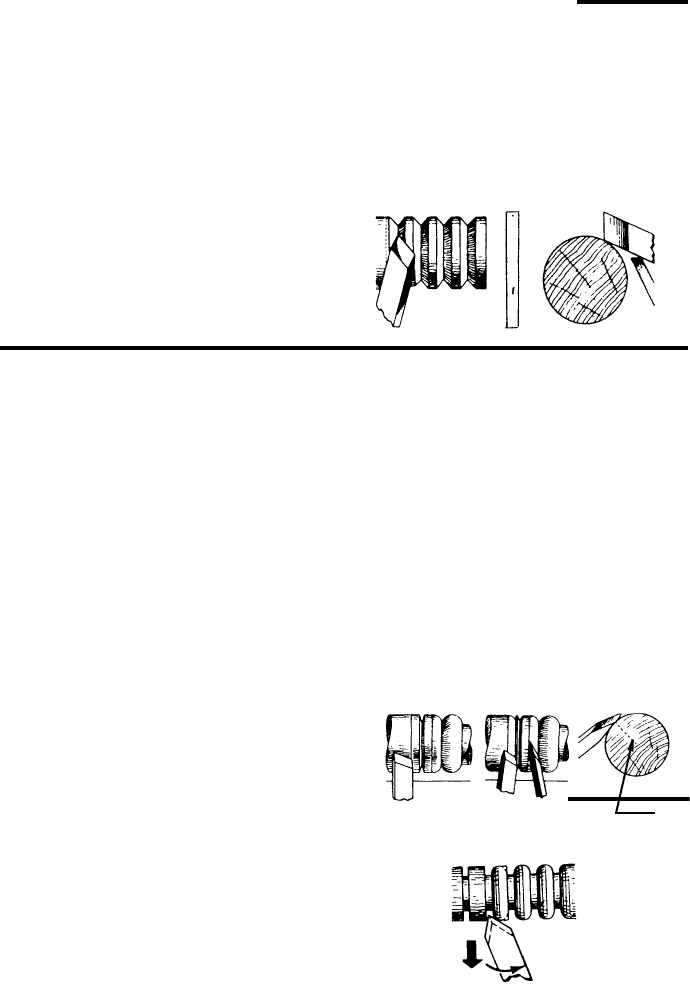

Cutting Beads

This requires considerable practice, First,

make pencil lines to locate the tops (high-

est points) of two or more adjoining

beads. Then make a vee groove at the

exact center between two lines - and

down to the desired depth of the separa-

tion between the beads. Be careful not to

make the groove too wide or you will

remove portions of the desired beads.

The sides of the two adjoining beads are

now cut with the heel of the skew - prefer-

ably 1/2-in. size, unless beads are quite

large. Place skew at right angles with the

work axis, flat against surface and well up

near the top. The extreme heel should be

just inside the pencil line that marks the

top of the bead. Now draw skew straight

back while raising handle slowly - until

edge of the heel at the pencil line starts to

cut.As edge begins to cut, roll skew in the

direction of the vee - so that the exact por-

tion of the edge which started cutting will

travel in a 90° arc down to bottom of the

vee. Upon reaching bottom of the vee, the

skew should be on edge. Reverse the

movements to cut side of the adjacent

bead.

It is important that only the extreme heel

should do the cutting. This means that the

bottom edge of the bevel next to the vee

must at all times be tangent to the arc of

the bead being formed.

Easier beads can be shaped with the

spear point chisel. Use pencil marks and

sizing cuts as before. Push the chisel

straight into each cut and rotate it horizon-

tally to round off the adjacent edges. It

must be moved slightly in the direction of

rotation at the same time, to keep the

point from digging into the adjacent bead.

Start

Second

Position

Finish

Bevel

Tangen

t

To Wor

k

Swing

Tool

Cutting

Beads