42

How to Use Your RIDGID Wood Lathe (continued)

Long Spindles

A long turning can be worked in short sec-

tions, with joints arranged to be at shoul-

ders where they will not be noticed.

Long thin work that is likely to whip while

turning should be supported at one or two

places by a backstick. This is easy to

make. A simple one consists of a short

length of wood mounted vertically in an

extra tool rest, and notched so that it can

be used to support the spindle from

behind.

Faceplate & Chuck Turnings

Planning The Work

Make a layout first, to provide a visual pat-

tern to follow while working the turning.

Patterns can be laid out in the same man-

ner as spindle patterns - or templates can

be made which can be held against the

work for visual comparison. Circles to

locate the various critical points (at which

the contours of the faceplate take distinct

form) can be quickly scribed on the rotat-

ing work by using the dividers.

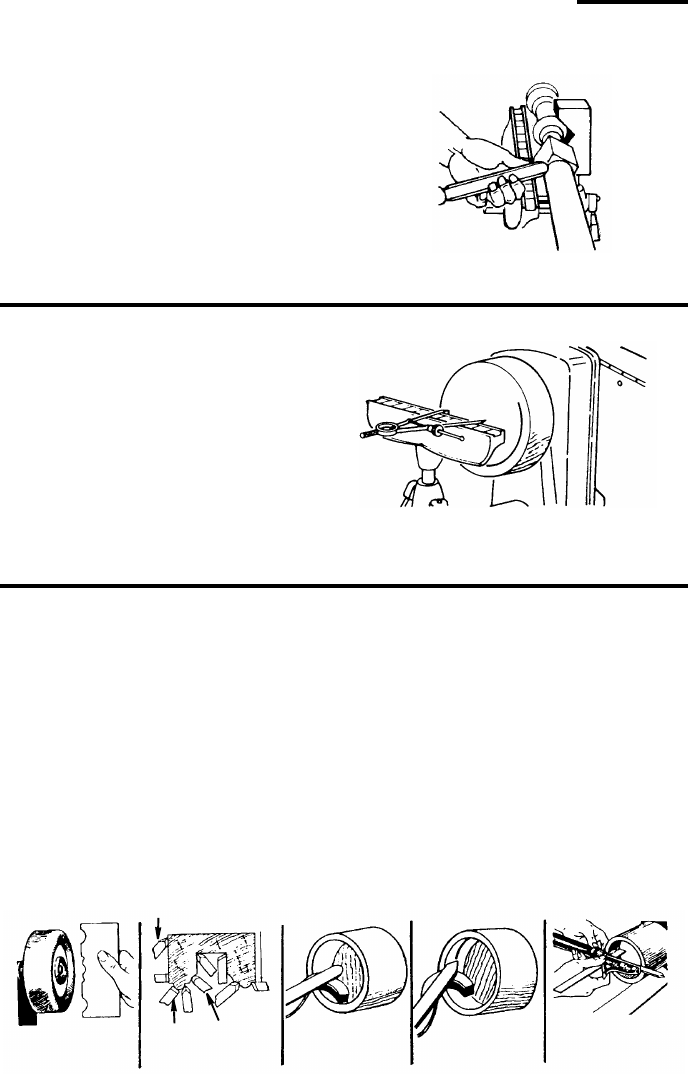

Planning Various Cuts

The circumference of a faceplate turning

is roughed-off and finished in the same

manner that a spindle is worked. Practi-

cally all of the balance of the operations,

however, are done by using scraping

methods. A few of the standard contours

which must often be turned are illustrated

in the accompanying sketch - which also

shows the proper chisels for shaping

these contours. Any roughing-out to depth

that must be done is generally accom-

plished with the gouge held in the scrap-

ing position.

Spear

Skew

Round

Nose

Checking Profile

with Cardboard

Planning

Various Cuts

Round Nose

Chisel

Spear-Point

Chisel

Measuring

Depth

Square

Nose

Template

6489c12wlEhalf_final.fm Page 42 Friday, April 25, 2003 3:40 PM