82.

INSTALLING A MOLDING HEAD SET

A

Molding Head Set may be used to add a variety of decorative

edges to a wood work piece. These edges are commonly seen on

trim moldings and furniture.

To reduce the risk of injury, always disconnect

p

lug from power source before changing

blades.

To reduce the risk of injury, always use the

Bosch Molding Table Insert No.TS1009.

Never

m

ake molding head cuts without this insert. Do not use molding

head sets larger than 7” diameter and with cutters wider than 1”.

Never set molding cutters to any bevel angle other than the vertical

0

° angle. Follow all warnings and instructions shown here and

those that accompany your molding head set. Failure to comply

with these warnings may result in serious bodily injuries.

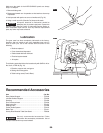

NOTE: Leave the inner washer in its original sawing position.

Install molding head, then outer washer, and then arbor nut. Check

that all cutters and the arbor nut are securely tightened. Some

molding head sets come with an additional thick washer/spacer;

this part is not used on the 4100 table saw.

1.Disconnect plug from power source. Raise saw blade to

maximum height.

2. Remove the Barrier Guard Assembly and Anti-Kickback Device

(see page 26). Lower and lock the Riving Knife in its lowest

position.

3. Remove standard table insert plate.

4. Remove the arbor nut and only the outer blade washer and saw

blade (see page 30).

NOTE: Leave inner blade washer on arbor

shaft.

5. Place molding head against inner washer (with cutters facing to

front of saw). Then place on the outer washer and tighten arbor

nut on arbor shaft.

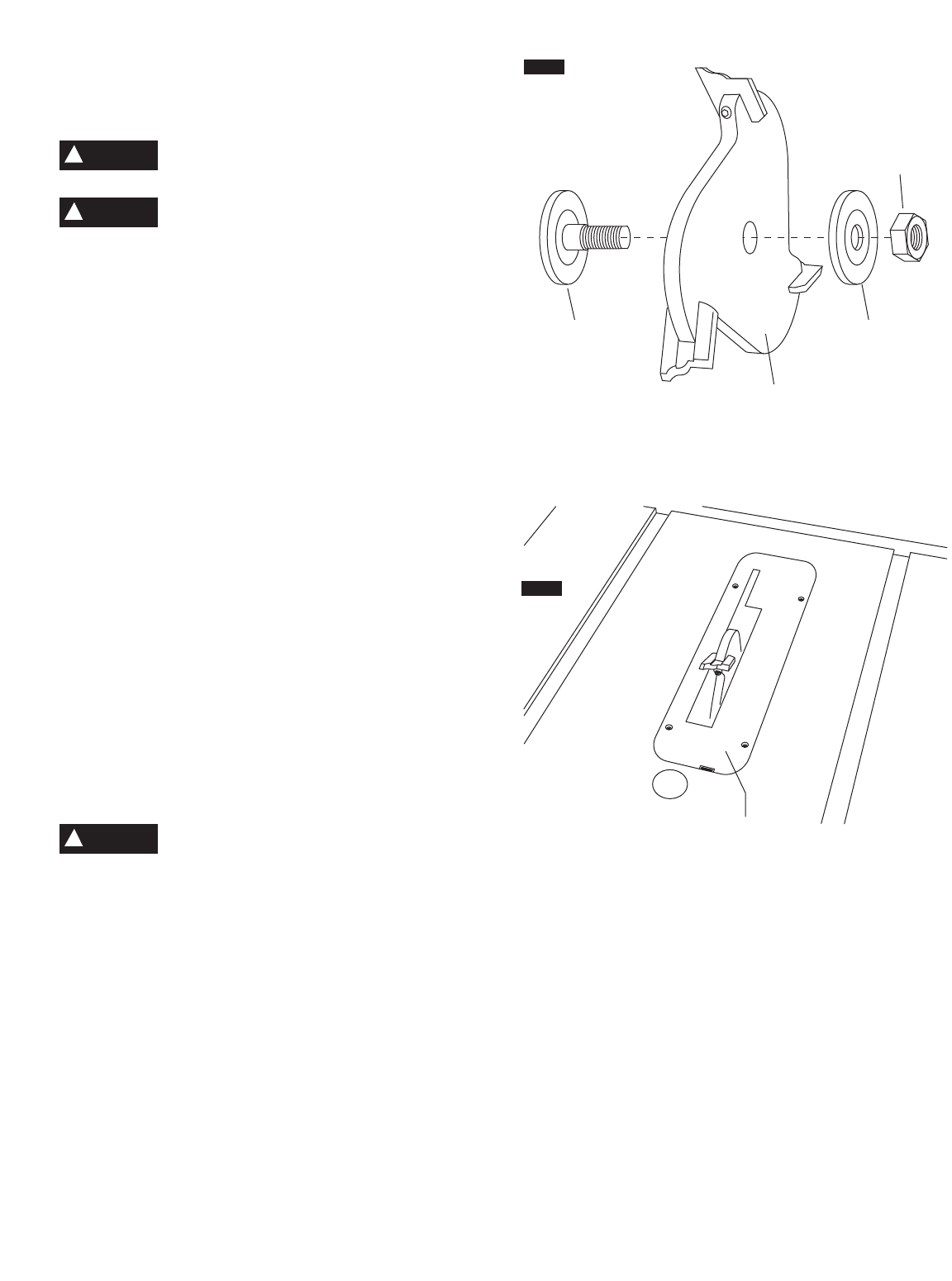

6. Lower the cutters below the table top and insert the Bosch

Molding Table Insert (TS1009) (Fig. 72). Raise the cutters to the

desired depth of cut (above the insert). Check that the tool is not

plugged into a power source; then carefully rotate the cutters by

hand to make sure all components are tightly held and no

interferences exist.

7. Plug saw into power source. Using scrap wood, make practice

molding cuts and adjust height accordingly.

To reduce the risk of injury, never pass your

hands over the cutting molding head cutters.

Molding cuts are non-thru (blind) cuts. Many times the cutters can

not be seen during cutting. See page 76 for instructions on non-

thru sawing. The work piece must be held against the saw's fence

as it is being fed. An auxiliary fence should be attached to the

saw's fence (see page 72). Never make freehand cuts. Whenever

possible, use push sticks and push blocks for molding cutting (see

page 74). Use feather boards and hold-downs, attached to the

table or fence (See page 76).

IMPORTANT: Follow all instructions

and warnings that come with your molding head set.

RETURNING SAW TO NORMAL THRU-CUTTING

After completing your Molding cutting, be sure to return the inner

and outer washers to the original positions (see page 30 for

details). It is important that the original equipment washers are in

the proper positions so that the saw blade always aligns with the

permanently installed riving knife.

WARNING

!

WARNING

!

WARNING

!

FIG. 71

I

NNER BLADE WASHER

R

ONDELLE DE LAME

INTERIEURE

ARANDELA INTERIOR

DE LA HOJA

M

OLDING HEAD

E

NSEMBLE DE LAMES A

M

OULURER

F

RESA DE MOLDURAR

O

UTER WASHER

RONDELLE EXTERIEURE

ARANDELA EXTERIOR

ARBOR NUT

ECROU DE FIXATION DE

L

'ARBRE

T

UERCA DEL EJE

P

ORTAHERRAMIENTA

MOLDING TABLE INSERT

PLAQUE AMOVIBLE DE

TABLE POUR MOULURAGE

ACCESORIO DE INSERCIÓN

DE LA MESA DE MOLDURAR

FIG. 72