INSTALLING WORK TABLE

NOTE: Apply coat of paste wax ;o the work table.

This will make it alittle easier to feed the work.

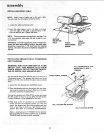

1. Loosen the table positioning screw.

2. Insert the table support rod in the hole in the base

until the edge of the table is approximately 1/16"

from the abrasive disc, Tighten the screw.

NOTE: There is asecond mounting hole in the base. This

is for mounting the table when the belt is used in a ver-

tical position.

WARNING: To avoid trapping the work or fingers be-

tween the table and sanding surface, the table edge

should be a maximum 1/16 inch from the sanding

surface, the table should be completely engaged on

the rod.

/

SECOND

MOUNTING

HOLE TABLE

POSITIONING

SCREW

\

TABLE

SUPPORT

ROD

INSTALLING ABRASIVE BELT-TENSIONING

AND TRACKING

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE REMOV-

ING OR INSTALLING ABRASIVE BELT.

On the smooth side of the abrasive belt you will find a DIRECTIONAL ARROW\

•dl"r - n ,

ectlonal arrow. The abras ve belt must run _,

in the

direction of this arrow so that the splice does not come

apart.

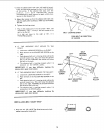

1. Loosen the two abrasive belt LOCKING screws.

2. Place the abrasive belt over the pulleys with the direc-

tional arrow pointing as shown. Make sure the abra-

sivebelt iscentered on both pulleys.

Turning the abrasive belt ADJUSTING screws will cause

the idler pulley to move in or out. When the idler pulley

is moved outward, it puts TENSION on the belt.

3. Place both of the ½" wrenches on the ADJUSTING

screws and pull the wrenches toward you. This will

stretch the abrasive belt. Move the wrenches back and

forth a few times so that you "'get the feet" of the

abrasive belt while it is stretching (TENSIONING).

/

BE LT ADJUSTING SCREWS

Apply a small amount of TENSION to the abrasive

belt by pulling the wrenches toward you, so that the

TENSION feels the same on both wrenches.

PULL WRENCHES IN THIS

DIRECTION TO APPLY

TENSION

BELT LOCKING SCREW

14