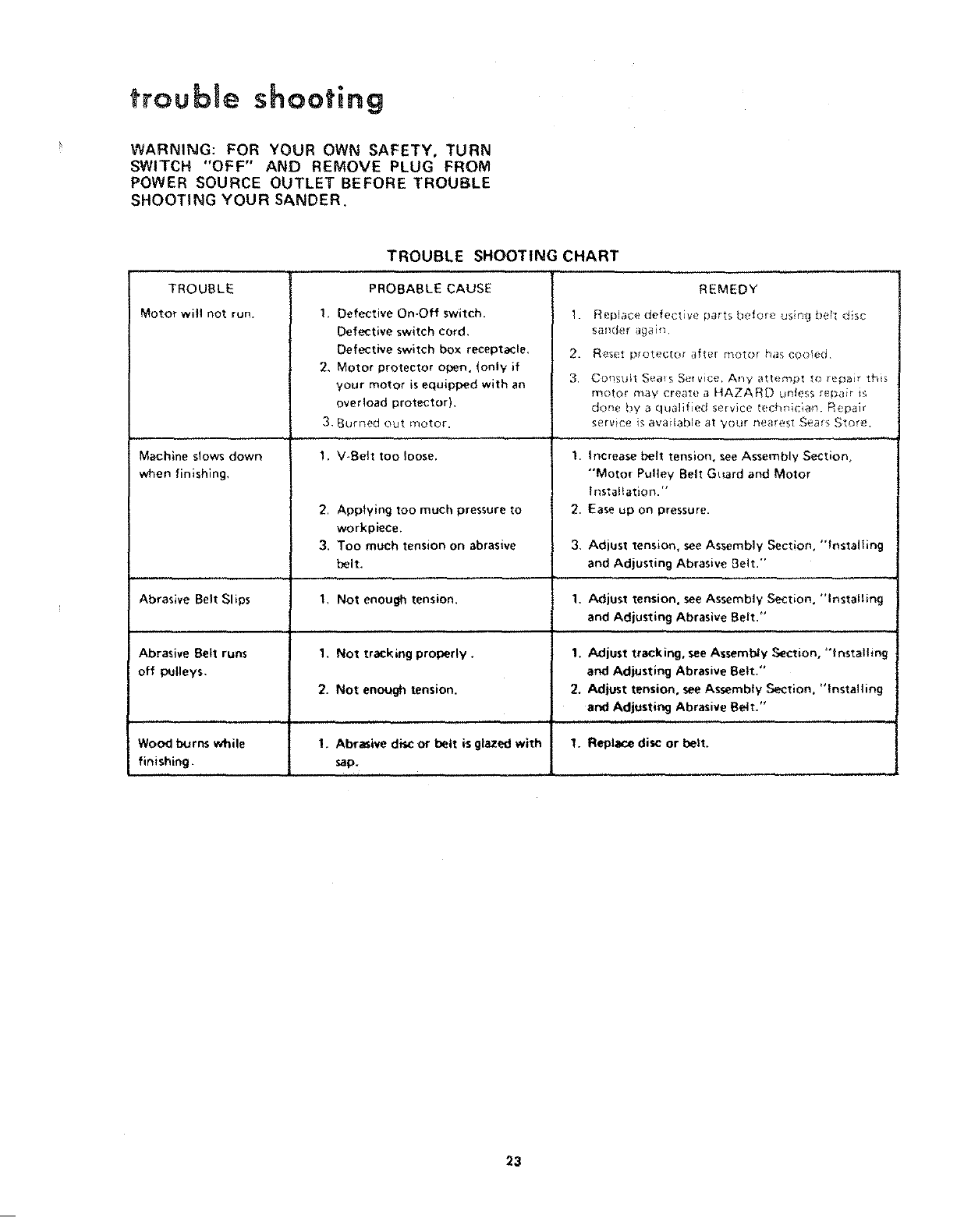

trouble shooting

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE TROUBLE

SHOOTING YOUR SANDER,

TROUBLE SHOOTING CHART

TROUBLE

Motor wd! not run.

Machine slows down

when finishing,

Abrasive Belt Slips

Abrasive Belt runs

off pulleys.

Wood burnswhile

finishing.

PROBABLE CAUSE

1, Defective On-Off switch.

Defective switch cord.

Defective switch box receptacle,

2, Motor protector open, (only if

your motor is equipped with an

overload protector),

3. Burr_ed out motor.

1. V-Belt too loose.

2. Applying too much pressure to

workpiece.

3. Too much tension on abrasive

belt.

1, Not enough tension.

1. Not tracking properly.

2. Not enough tension.

1. Abrasive disc or belt is glazed with

sap.

1.

2.

3.

REMEDY

Replace defective pa_ts before ,4sing b!!l_ dsc

sai_(ler agai_

Reset p_otector after motor has cooled

Coqsuit S_!a!s S_!TvI(;e, Ally attemt.)t ._olepa_ this

motor may £reate a HAZARD urtfe_s r_;t_air ts

clon_ by a qualified service techr_icia_. Repair

service is available at your nearest Sears Store.

1. Increase belt tension, see Assembly Section,

"Motor Pulley Belt Gtlard and Motor

InstaUation."

2. Ease up on pressure.

3, Adjust tension, see Assembly Section, "fnstaliing

and Adjusting Abrasive _3elt."

1. Adjust tension, see Assembly Section, "Installing

and Adjusting Abrasive Belt."

1, Adjust tracking, see Assembly Section, "'Installing

and Adjusting Abrasive Belt."

2. Adjust tension, see Assembly Section. "Installing

and Adjusting Abrasive Belt."

t. Replace dis(: or belt.

23