maintenance

WARNING: FOR YOUR OWN SAFETY, TURN

SW|TCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE ADJUST-

ING, MAINTAINING, OR LUBRICATING

YOUR FINISHING MACHINE.

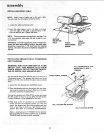

Keep your machine and your workshop clean. The dust

traos around the abrasive disc and the abrasive belt are

designed to deflect most of the fine dust. They should be

connected to a Mac for most efficient dust removal

WARNING: DO NOT ATI'ACH AVACWHEN FINISHING

IRON DR STEEL. THE SPARKS COULD IGNITE THE

DEBRIS AND CAUSE A FIRE,

(f power cord ts worn or cut, or eamaged in any way

have _treplaced immediately.

Frequently blow oat any dust that may accumulate

inside the moto_

A coat of automobge-type wax applied to the work-

table wd{ make it a little easier to feed the work while

finishing,

Do not apply wax to the abrasive belt table because the

belt could Dick uD the wax and deposit it on the pulleys,

causing the'belt to sli_.

MOTOR MAINTENANCE AND

LUBRICATION

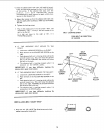

1 The bearings, in both end stllelds Of the motor, have been

lubricated at the factory with correct lubricant No other

part of the motor reautres lubrtcabon

2 Re-lubricate motor bearings in accordance with the

instructions ontne nameplate Be sure to wipe off dirt or

grit if present around od hole capsto prevent anypossibd_ty

of foreign material eontaminapng the oil wicks that supply

the bearings with oil Use a good grade of rrled{um weight

mineral ell. SUCh as automobde engine oil, SAE 20.

3 If disassembl_ of [ne motor is necessary, it should be

returned to your nearest Sears retad or mall order store {n

order to prevent vo=dtng the guarantee

NOTE: The s[_eea of thts motor cannot be regulated or

changed

4. Ever. effort should De made to prevent fore=gn material

from entering me motor. When operated under conddlons

_KetVtO Dermtt accumulatlor3s of (Just, dirt, or waste wdh_ n

the motor a visual insDection should be made at frequent

mterva=s Accumulations of dr,/dust can usually be blown

out successful[,.

NOTE: Motors usedon wood-working tools are parbcularly

Suscepttble TOthe accumulatton of sawdust and wood ch=ps

and should be blown out or "vacuumed" frequently to

prevent nterference WITh normal motor ventilabon and

proper ouerat=on ot the centrifugally-operated starting

SWlta[1,

lubrication

The BEARINGS in this machine are packed with grease at

the factory. They requtre no further lubrication.

Periodically lubrlcate the cams and shafts in the idler pulley

mechanism with Silicon Spray.

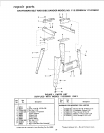

SEARS RECOMMENDS THE

FOLLOWING ACCESSORIES

ITEM CAT. NO.

Steel Stand .............................. 9-22213

Caster Set ....................... 9-22222, 9-22221

Miter Gauge ............................. 9-29929

Pressure*Sensitive cement .................... 9-2220

Abrasive Belts and Disc .............. SEE CATALOG

Steel Legs ............................. 9-22236

Power Tool Know How Handbooks

Radial Saw .............................. 9-2917

Table Saw .............................. 9-2918

Sears may recommend other accessories not listed in the

manual, See your nearest Sears store or catalog department

for other accessories. Do not use any accessory unless you

have received and read complete instructions for its use.

i i¸

_'i " i i_ ,ii i_i_

22