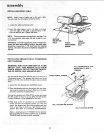

BELT ADJUSTING

SCREW

(ONE ON EACH SIDE)

1. ABRASIVE BELT ADJUSTING SCREWS

cause the idler pulley to move in or out for applying

tension to the abrasive belt or for tracking it. They

are adjusted using the 1/2" wrenches,

See "Assembly" section... "Installing Abrasive Belt".

2. ABRASIVE BELT LOCKING SCREWS lock

the adjustment mechanism after the abrasive belt is

tensioned and tracking properly, They are locked

using the 1/2" wrench.

See "assembly" section . . . "Installing Abrasive

Belt".

BELT LOCKING

SCREW

(ONE ON EACH SIDE)

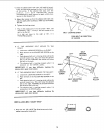

3,

WORK TABLE TILT LOCK SCREW locks

the table. It islocked using the 1/2" wrencn.

a. Using a combination square, check the angle of

the table with the disc.

NOTE: The :ombination square must be "true"--

See start of assembly section on Pg. 6 for checking

method.

b. If the table Js not 90 ° with the disc.., loosen

tilt Ic_ck screw and ti t table,

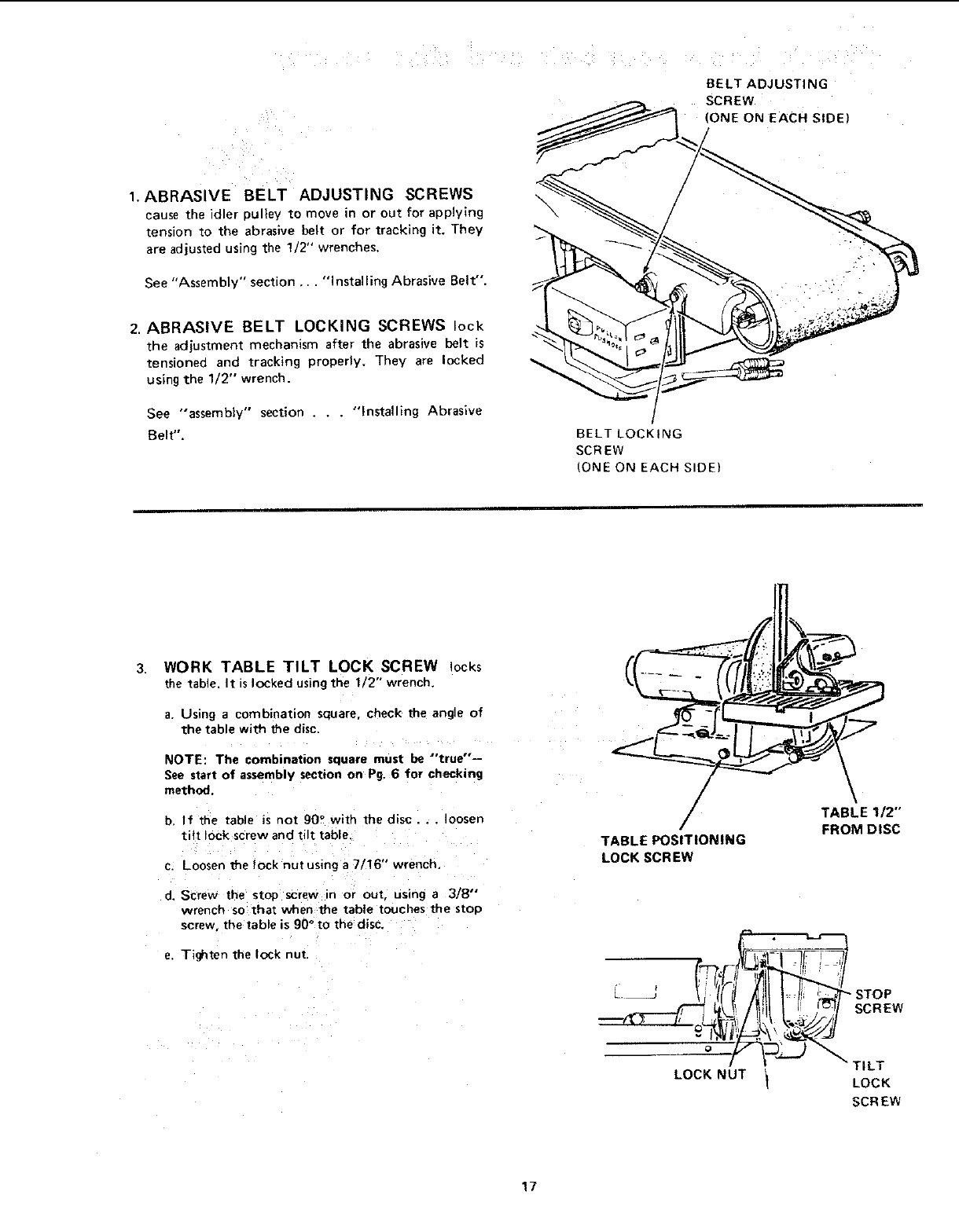

c. Loosen the lock nut using a 7/16" wrench.

d. Screw the atop screw in or out. using a 3/8""

wrench so that when the table touches the stop

screw, the table is 90° to the disc.

e. Tighten the lock nut

/

TABLE POSITIONING

LOCK SCREW

\

TABLE 1/2"

FROM DISC

LOCK NUT

STOP

SCREW

_" TILT

LOCK

SCREW

17