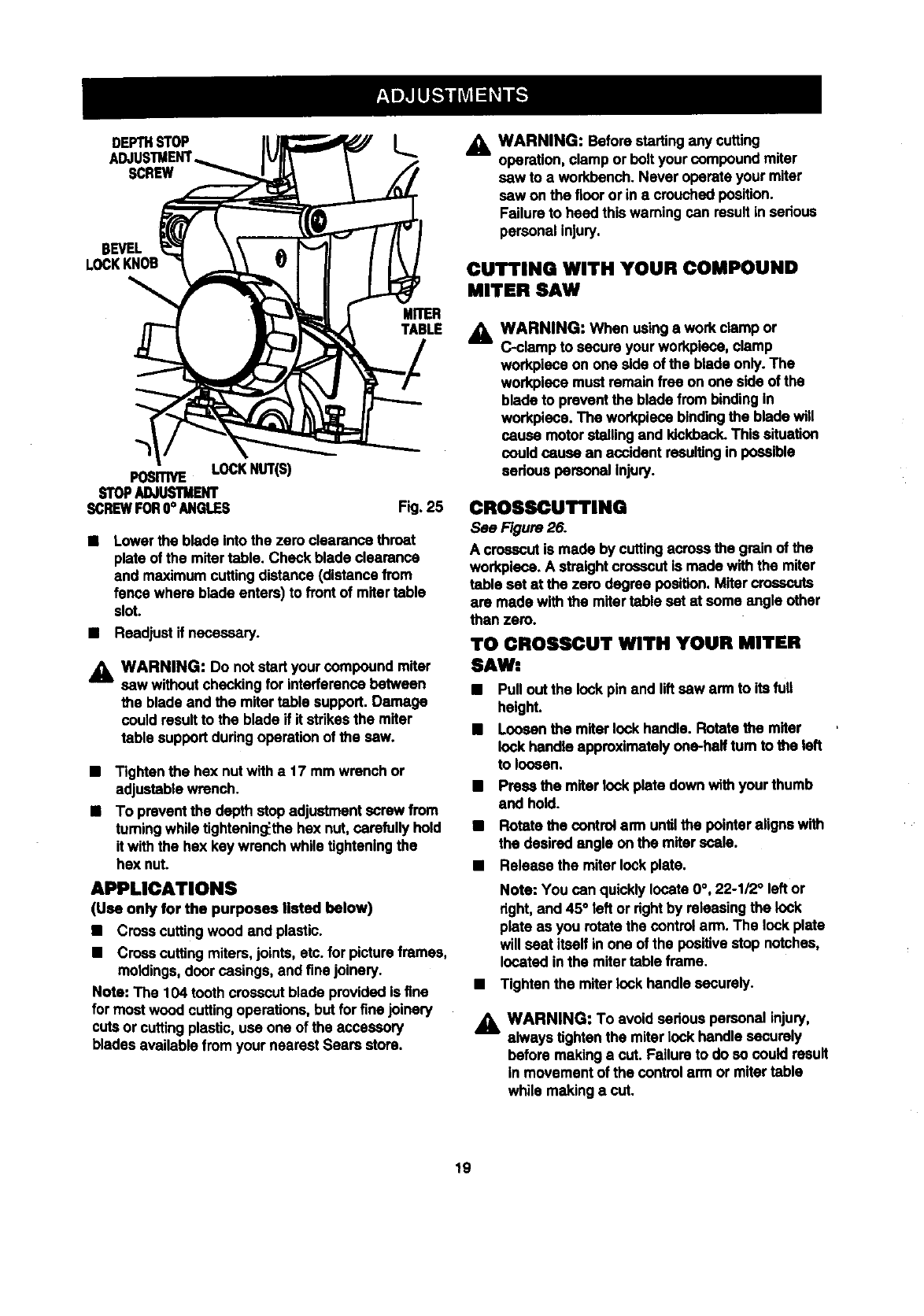

DEPTHSTOP L...

SCREW

BEVEL

MITER

TABLE

POSITIVE LOCKNUT(S)

STOPADJUSTMENT

SCREWFOR0°ANGLES Fig,25

Lowerthe blade intothe zero clearancethroat

plate ofthe mitertable. Check blade clearance

and maximumcuttingdistance(distancefrom

fencewhere blade enters) to front ofmitertable

slot.

• Readjustif necessary.

_k WARNING: Do not startyourcompound miter

sew withoutcheckingfor interferencebetween

the bladeand the mitertable support.Damage

couldresultto the blade if it strikesthe miter

table supportduringoperationofthe saw.

• Tightenthe hex nutwith a 17 mm wrench or

adjustablewrench.

• To preventthe depth stop adjustmentscrew from

tumingwhiletightening_thehexnut,carefullyhold

itwiththe hex key wrenchwhiletighteningthe

hsx nut.

APPLICATIONS

(Use only for the purposes nsted below)

• Crosscuttingwood and plastic.

• Crosscuffingmiters,joints,etc. for pictureframes,

moldings,doorcasings, and fine joinery.

Note: The 104 toothcrosscutblade providedis fine

for mostwoodcuttingoperations,but for fine joinery

cutsor cuffingplastic,use one of the accessory

bladesavailable from your nearest Sears store.

WARNING: Beforestartingany cutting

operation,clamp or bolt yourcompoundmiter

saw to a workbench. Never operate yourmiter

sew on the flooror in a crouchedposition.

Failureto heed this warningcan resultin serious

personalinjury.

CUTTING WITH YOUR COMPOUND

MITER SAW

_, WARNING: When usinga work clamp or

C-clamp tosecure yourworkpieca,clamp

workpieceon one side ofthe blade only.The

workpiscemust remainfree on one side ofthe

blade to preventthe blade frombindingin

workplece. The workpiecebindingthe bladewill

cause motorstallingand kickback.This situation

could cause an accident resultingin possible

sedous personalInjury.

CROSSCUTTING

See Figure26.

A crosscutis made bycuttingacrossthe grain of the

workplace.A straightcrosscutis made with the miter

table set at the zero degree position. Mitercrosscuts

are made withthe mitertable set at some angleother

then zero.

TO CROSSCUT WITH YOUR MITER

SAW:

• Pullout the lockpin and liftsew arm to itsfull

height.

• Loosenthe miterlockhandle. Rotate the miter

lock handle approximatelyone-half tum tothe left

to loosen.

• Pressthe miter lockplate down with yourthumb

and hold.

• Rotate the controlarm untilthe pointer alignswith

the desiredangle on the miterscale,

• Release the miter lockplate.

Note: You can quicklylocate 0°, 22-1/2° leftor

dght, and 45' left or rightby releasingthe lock

plate as you rotatethe control arm. The lock plate

willseat itselfin one of the positivestop notches,

locatedinthe mitertable frame.

• Tighten the miter lock handlesecurely.

WARNING: To avoidsedous personalinjury,

always tightenthe miterlock handle securely

before makinga cut. Failuretodo so couldresult

in movementofthe controlarm or mitertable

while makinga cut.

19