G1022 Series Table Saws -47-

V-Belt

The sealed ball bearings in the motor and

throughout the Model G1022 require no mainte-

nance during their lifetime. When they do wear

out, replacements can be obtained through the

Grizzly Parts Department.

Lubricate the areas indicated below every 12

months:

BLADE ANGLING TRUNNION—The front and

back trunnions each have a semi-circle groove

that needs to be lubricated with an automotive

wheel bearing grease.

BLADE HEIGHT TRUNNION—The blade height

trunnion pivots on a steel rod. This should be

lubricated with 6 or 7 drops of light machine oil.

WORM GEARS (

Figure 58)—

These should be

lubricated with an automotive wheel bearing

grease.

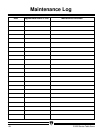

Lubrication Table

The table is made from cast iron. If preventative

measures are not taken, the table surface will rust.

Regularly wipe sawdust from the table to prevent

rust causing moisture from becoming trapped

against the table. Regular applications of products

like SLIPIT

®

will prevent rust as the saw is used on

a daily basis. For long term storage, use products

such as Boeshield T-9

®

. Both of these products

are available in the Grizzly catalog.

Inspect the V-belt regularly for tension and wear.

Check the pulleys to ensure they are correctly

aligned. Refer to Section 5: Set Up beginning on

Page 23 for instructions on adjusting the V-belt.

Figure 58. Worn gear lubrication points.

Lubrication Points