G0644 15" Open-End Wide Belt Sander

-25-

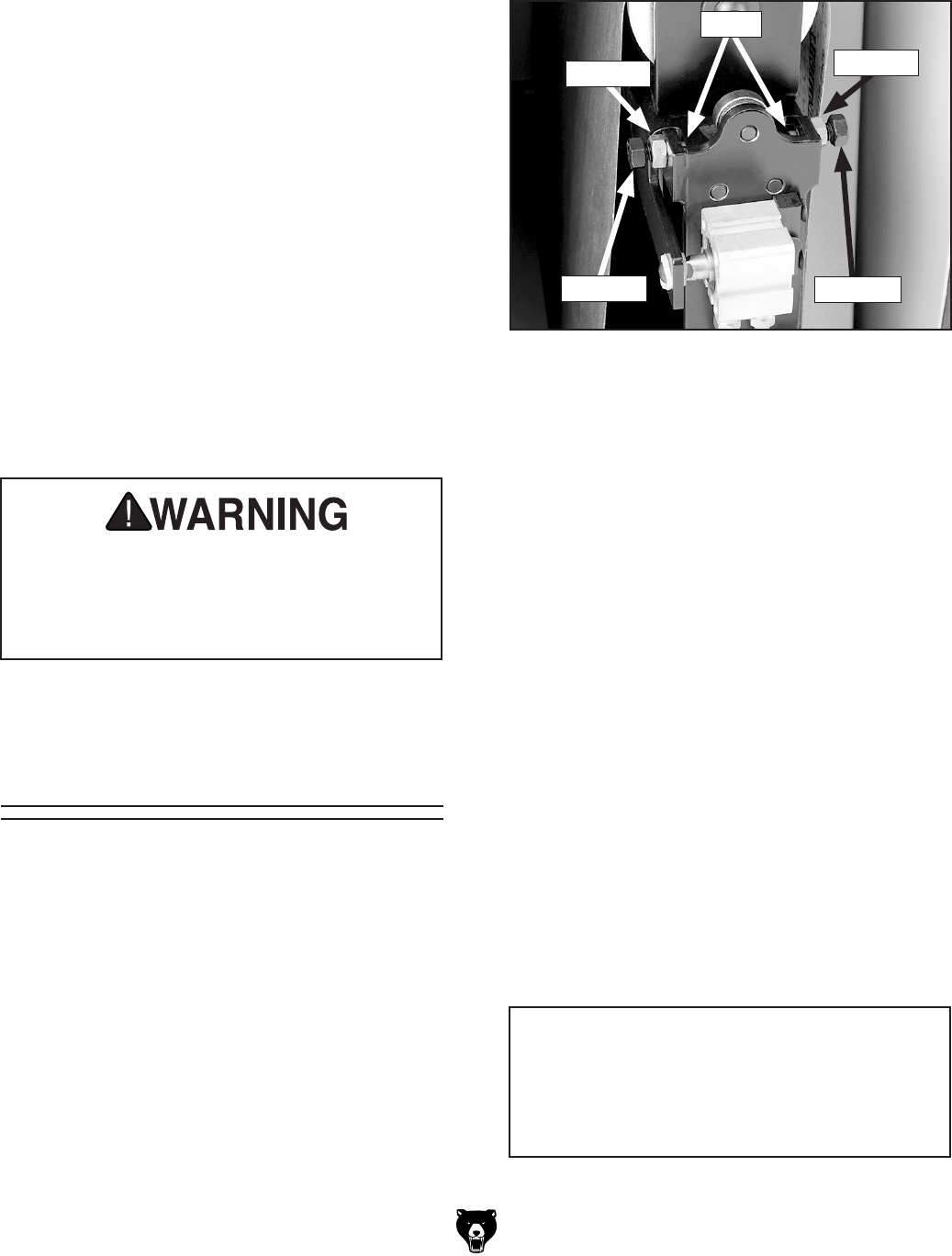

Sanding Belt

Oscillation Rate

To prevent sanding "streaks" in the workpiece,

the sanding belt oscillates from side-to-side on

the sanding drum during operation. This action

is caused by the twisting motion of the upper

sanding roller, and is automatically controlled by

a pneumatic piston and lever system inside the

sanding cabinet.

We recommend that one oscillation cycle (the

movement of the sanding belt from one side to the

other) should be 4–6 seconds.

Note: You will hear a metallic "thump" when the

sanding belt changes oscillation direction. This

noise is normal.

The rate of sanding belt oscillation can be

changed by adjusting the oscillation stops shown

in Figure 25

.

NOTICE

The sanding belt oscillation system requires

compressed air connected to the machine

and adjusted to 57 PSI. Without this com

-

pressed air, the sander will not operate.

To adjust the sanding belt oscillation rate:

1. DISCONNECT THE SANDER FROM

POWER!

2. Open the sanding belt access door and iden-

tify the oscillation stops shown in

Figure 25.

3. Use a 12mm wrench to loosen the oscillation

stop jam nuts, and adjust the oscillation stop

hex bolts equally in or out to change the oscil

-

lation rate.

Note: The farther in towards the center you

adjust the hex bolt, the slower the sanding

belt will oscillate for that direction of move

-

ment. Experiment to find the right oscillation

rate for your operation.

4. Re-tighten the jam nuts, and close the access

door.

5. Connect the machine to power, start the

sanding motor, and check the oscillation rate.

Repeat Steps 1–4 if necessary.

Figure 25. Sanding belt oscillation stops.

Jam Nut

Jam Nut

Hex Bolt

Hex Bolt

Stops

• When sanding workpieces with irregular

widths, take very light sanding passes to pre

-

vent gouges. As the width of the workpiece

decreases, the load on the sanding motor will

reduce and the sanding drum will speed up,

causing a gouge.

• DO NOT edge sand boards. This can cause

boards to kickback, and may result in serious

personal injury. Edge sanding boards also

can cause damage to the conveyor belt and

sandpaper.

• Feed the workpiece into the sander at an

angle to maximize stock removal and sand

-

paper effectiveness, but feed the workpiece

straight to reduce sandpaper grit scratches

for the finish passes.

• When sanding workpieces with a bow or

crown, place the high point up, which pre

-

vents the workpiece from rocking, and take

very light passes.

DO NOT sand more than one board at a time

side-by-side. Minor variations in thickness

can cause one board to be propelled at a

high speed of rate by the sanding belt and

could result in serious personal injury.