-34-

G0644 15" Open-End Wide Belt Sander

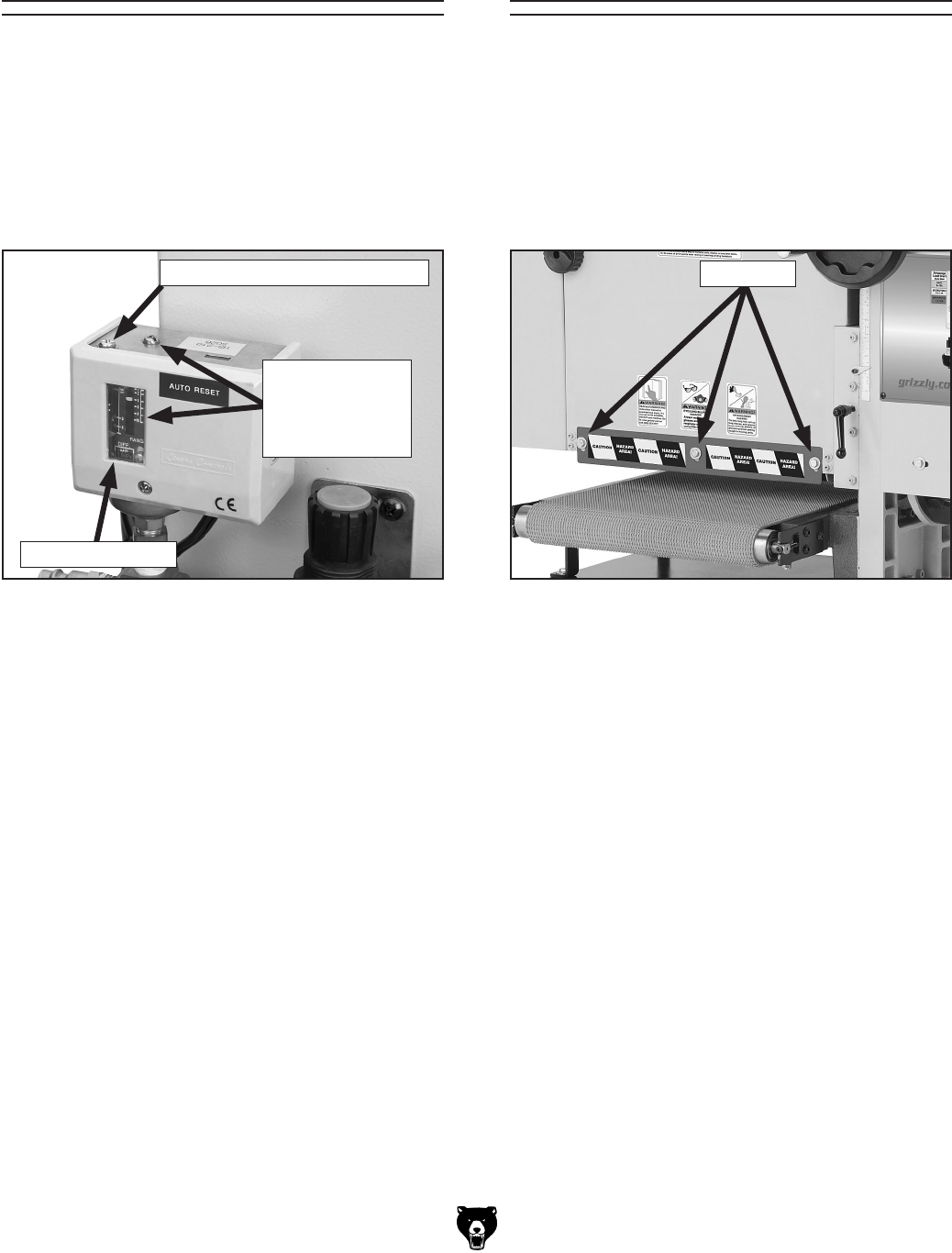

Air Pressure Safety

Switch

The sanding motor safety brake and the sanding

belt oscillation system require at least 57 PSI of

air pressure connected to the machine to oper

-

ate correctly. The air pressure safety switch (see

Figure 36

) measures the amount of air pressure

flowing into the machine. If there is not adequate

air pressure, the air pressure safety switch will not

allow power to flow to the sander.

The air pressure safety switch was calibrated

and set at the factory and should not require any

further adjustment. However, we recommend that

you verify the settings.

The red pointer on the sensitivity scale should be

set at "0" on the scale, which is adjusted with the

sensitivity adjustment screw shown in Figure 36.

The left minimum air pressure scale should read 4

kg/cm

2

, which is adjusted with the related adjust-

ment screw.

air pressure switch

Adjusting Depth Of

Cut Safety Bar

When properly adjusted, prevents the operator

from exceeding the maximum depth depth of cut.

The position of this safety bar (see Figure 37

)

was factory set at approximately

3

⁄64" (0.047")

above the lowest point of the sanding drum. We

recommend that this safety bar remain at this set

-

ting.

To adjust the depth of cut safety bar to the

factory setting:

1. Make sure the sanding drum and conveyor

are parallel (

Page 32).

2. Sand a 15" wide piece of stock until it is flat.

3. DISCONNECT THE SANDER FROM

POWER!

4. Open the sanding belt access door and

remove the sanding belt from the sander.

Figure 37. Depth of cut safety bar.

Hex Bolts

depth of cut safety bar

Figure 36. Air pressure safety switch.

Minimum Air

Pressure

Adjustment

Screw & Scale

Sensitivity Scale

Sensitivity Adjustment Screw